25

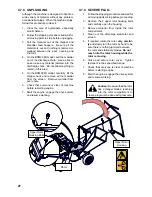

4�7�5 CHIPPING / SHREDDING

Before beginning work, it may be helpful to sort

the material into separate piles for chipping and

shredding. The chipper has a

3" (76 mm)

diameter

maximum capacity and the shredder has a

3/4" (19

mm)

diameter maximum capacity

Always wear personal protective equipment (

PPE)

whenever operating the machine. This includes

but is not limited to a hard hat, protective shoes

with slip resistant soles, protective goggles or

face shield, heavy gloves, hearing protection and

protective clothing.

Do not place metal, bottles, cans, rocks, glass

or other solid material into the wood chipper. If

something like this gets into the machine, stop the

machine immediately for a detailed inspection.

If opening up any guards for inspection, always

put the machine in

safe condition

:

• disengage the drive

• shut off the engine

• ensure components have stopped moving�

• unplug spark plug cable

• turn fuel valve off

• block & chock the wheels

Inspect machine for damaged or loosened parts,

repair or replace parts as required before resum

-

ing work.

Chipper Feed

When the rotor is up to speed:

• Carefully slide the wooden material into the

chipper feed hopper and move it into the

rotor. As you begin to feed, the rotor will tend

to draw the material through.

• Do not force the material with into the

hopper and rotor, slow steady pressure is

best.

• If the rotor begins to slow down, stop and let

the rotor get back up to speed, then restart

feeding.

• Do not reach into the feed hopper further

than the hopper opening, to avoid contact

the blades on the rotor.

• Use a stick or branch to push any piece of

material into the rotor that does not move

on its own and stops in the hopper.

• Any remaining tree, brush or limb less than

3/4 (19 mm) in diameter or very bushy, can

be fed through the shredder.

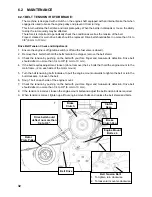

Shredder Feed

When the rotor is up to speed:

• Place the leafy/wooden material into the

shredder feed hopper until the hopper is full.

• Use the shredder feed control handle on the

side of the hopper to open the feed gate.

You can control how much and how fast

the material is delivered into the shredder

by varying the gate opening.

• If the shredder begins to slow down, stop

and let the shredder get back up to speed,

then restart feeding.

• Do not reach into the shredder feed hopper

further than the gate to avoid contact with

the knives on the rotor.

• Use a stick or branch to push any piece of

material into the knives that does not move

on its own and stops in the chipper housing.

• Release the handle and the gate will close.

Ensure the gate is closed between feeds

to keep flying material contained in the

shredder housing.

Do not prop open the

gate�

Z94120

Caution:

Do not

reach into the feed

hopper at any time,

use a stick or branch to push

any piece of material into the

rotor that does not move on

its own. If the jam persists

then stop the engine and wait

for the rotor to stop and then

clear the jam.

Do not chance getting

your hand caught in the

rotor�