12

2�8 OPERATING SAFETY

1.

Please remember it is important that you

read Chipper / Shredder. Clean or replace all

safety signs if they cannot be clearly read and

understood. They are there for your safety, as

well as the safety of others. The safe use of

this machine is strictly up to you, the operator.

2.

All things with moving parts are potentially

hazardous. There is no substitute for a cau

-

tious, safe-minded operator who recognizes

potential hazards and follows reasonable

safety practices. The manufacturer has

designed the BXMC Chipper / Shredder to

be used with all its safety equipment properly

attached, to minimize the chance of accidents.

Study this manual to make sure you have all

safety equipment attached.

3.

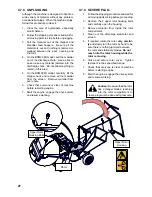

Close and secure rotor cover before operat

-

ing.

4.

Close and secure all guards, deflectors and

shields before starting and operating.

5.

Read and understand operator's manual

before starting. Review safety instructions

annually.

6.

Personal protection equipment including hear

-

ing protection, hard hat, safety glasses, safety

shoes, and gloves are recommended during

assembly, installation, operation, adjustment,

maintaining, repairing, removal, or moving.

Do not allow long hair, loose-fitting clothing, or

jewellery to be around moving parts.

7.

Never place any part of your body where it

would be in danger if movement should occur

during assembly, installation, operation, main

-

tenance, repairing, unplugging or moving.

8.

Before servicing, adjusting, repairing or

unplugging:

perform the "safe condition"

procedure:

•

disengage the drive

•

shut off the engine

•

ensure components have stopped moving�

•

remove spark plug cable

•

turn fuel valve off�

•

block & chock the wheels

9.

Do not run machine inside a closed building to

prevent asphyxiation from engine exhaust.

10.

Use care when feeding material into chipper.

Do not send metal, bottles, cans, rocks, glass

or other foreign material into wood chipper.

If foreign material enters chipper, stop using

the machine,

perform the "safe condition"

procedure�

Inspect machine for damaged or loose parts

before resuming work.

11.

Never use alcoholic beverages or drugs which

can hinder alertness or coordination while

operating this equipment. Consult your doc

-

tor about operating this machine while taking

prescription medications.

12.

During transport, do not allow riders on this

machine at any time. There is no safe place

for any riders.

13.

Never allow children or unauthorized people

to operate or be around this machine.

14.

Do not reach into rotor or feed hopper open

-

ings when the engine is running. Install and

secure access covers before starting engine.

15.

Keep the working area clean and free of de

-

bris to prevent tripping. Operate only on level

ground.

16.

Do not point discharge at people, animals or

buildings. Rotor can expel wood chips fast

enough to cause injury.

17.

Do not move or transport chipper when the

rotor is turning.

18.

Do not exceed a safe travel speed when

transporting.