Maintenance Instructions

H37i

Checking and Servicing

62

Fuel Lines and Clamps

NOTE:

The engine fuel injection system is pres-

surized and should only be serviced by a Walker

dealer or authorized Briggs & Stratton service

dealer.

Every year,

inspect the fuel supply lines from the

tank(s) to engine for deterioration or damage.

Also, inspect the fuel line

clamps for tightness.

Good preventive maintenance calls for complete

replacement

of fuel lines and clamps

every two

(2) years.

Engine Starter

Yearly or every 500 hours

disassemble and clean

the solenoid shift starter. Refer to the Briggs &

Stratton Service Manual for this procedure or con-

tact an authorized Briggs & Stratton engine dealer

to perform this service.

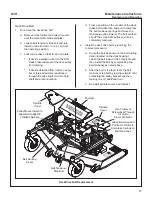

Transmission Control Setting

On a

yearly

interval or when an out-of-adjustment

condition is observed, check the transmission

control for proper function as follows:

Neutral-Park

With the mower parked on level ground, start and

run the engine, first at idle and then normal operat-

ing speeds. With the FSC in the

NEUTRAL-PARK

position, there should be no movement of either

drive tire. If the tire(s) are “creeping” forward or

reverse, refer to

Adjustments for Transmission

Control Step 3 - Neutral Function Adjustment on

page 71.

Straight Ground Tracking

Check for straight ground track by driving on a

smooth, level surface with hands off the steering

levers. Set the FSC at different speeds and

observe if the mower moves in a straight line (use

a cement joint or other line on the ground for refer-

ence). If the machine is drifting to the right or left,

refer to

Adjustments for Transmission Control Step

5 - Straight Tracking Adjustment on page 72.

Blade Brake Action

WARNING

It is important to check and maintain blade

brake action for safe operation of the ma-

chine.

Check the function of the cutter blade brake by

engaging the blade clutch (PTO), operating the

engine at full throttle, then disengaging the clutch

and measuring how quickly the blades stop.

Watch the rotation of the blade drive shaft as a

visual indi cation that movement has stopped. If

the brake is

working properly, all rotation will

stop five (5) seconds after disengagement

of

the clutch. If the brake system malfunctions—

blades do not stop in five (5) seconds—adjust or

repair the brake before operating the mower.

Refer to

Adjustments for Clutch Disengagement/

Brake Action

Step 2 - Blade Brake Band Adjust-

ment on page 76

.

PTO U-Joints

The PTO U-joints should be inspected

yearly

for

looseness and wear. If either is noticed, the

respective shaft or tube should be replaced. A

worn U-joint can cause vibration and extensive

damage to the PTO and the whole machine.