32

VERSION 01/2018

ORDER NUMBER DOC 2385674

TOPFINISH Bell 1S

6.5

AIR QUALITY, AIR QUANTITY AND AIR PRESSURE

The required air quality (see Chapter

) must be complied with, to ensure a long life

for the high-speed rotary atomizer. Furthermore, every kind of air contamination impacts

negatively on the spray and/or paint result.

The air filter should be fitted as close as possible to the valves and/or applicator The filter

units must be regularly checked and cleaned/replaced as required.

Do not use PTFE tape and adhesives in the supply pipe for the bearing air because they

may cause damage to the air bearing.

The air bearing must either be operated using a WAGNER controller or monitored on site

using an air filter (5 µm). The WAGNER controller contains the safety technology needed.

The bearing air (BA) has to be supplied separately without a shut-off valve supplied by the

customer. In accordance with local requirements, equip the mains air supply with a shut-

off valve supplied by the customer if required. If necessary, this shut-off valve could be shut

off if a fire alarm sounds or under other conditions.

The air supply to the bearing air, on the other hand, must be ensured at all times. A drop in

the bearing air (BA), with the hollow shaft rotating, may damage the air bearing. In extreme

cases, total loss of the air bearing is possible.

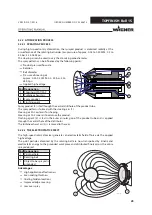

P_06099

Mains air

Shut-off valve (supplied by the customer)

Bearing air (BA)

Control cabinet

TOPFINISH Bell 1S

The bearing air (BA) should only be shut off if the bell plate is stationary. In this case,

WAGNER recommends a delay time of 200 s in the chain of stopping the bell plate and

shutting down the bearing air. The WAGNER controller includes this safety interlock and

monitors the bearing air (BA) by means of a pressure switch and the air hose (BAM) as an

input into the pressure switch.

If pressure fluctuations or power cuts occur more frequently, we would recommend

integrating an additional buffer tank to supply air for the bearing air. This buffer tank

should have a capacity of at least 25 l.

Opening of the product valves by means of an interlock should only be possible as of a

speed of 10,000 rpm.