22

OPERATING MANUAL

VERSION 07/2017

ORDER NUMBER DOC 2349369

8

CLEANING AND MAINTENANCE

8.1

CLEANING

8.1.1 CLEANING STAFF

Cleaning work should be undertaken regularly and carefully by qualified and trained staff.

They should be informed of specific hazards during their training.

The following hazards may arise during cleaning work:

- Health hazard from inhaling solvent vapors

- Use of unsuitable cleaning tools and aids

8.1.2 FLUSHING AND CLEANING THE SPRAY GUN

The spray gun and the device must be

cleaned and flushed daily. The cleaning

and flushing agents used must be

compatible with the working material.

Note:

Methylene chloride is not recommended

as an agent for flushing or cleaning the

spray gun or other system components.

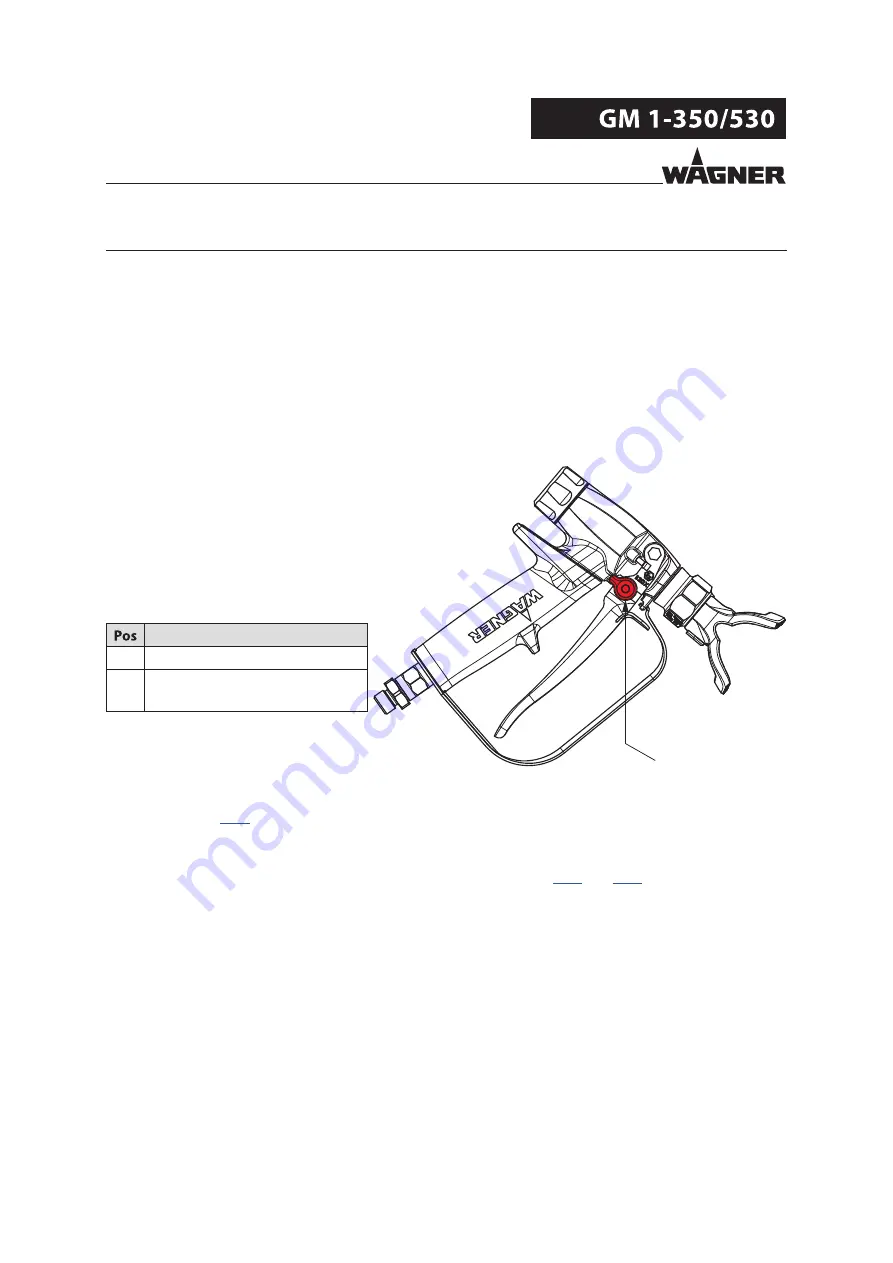

Description

1

Product inlet

2

Locking device in secured

position

B_5045

1

2

1. Relieve the pressure on the spray gun and product pressure generator in accordance

with Chapter

2. Secure the spray gun with the locking device.

3. Connect the solvent supply.

4. Disassemble the Airless nozzle and clean it separately (see Chapter

and

).

5. Raise the pressure of the rinsing agent supply to a maximum of 4 MPa; 40 bar; 580

psi, unlock the spray gun and thoroughly rinse it.

6. Relieve the pressure on the spray gun and product pressure generator.

7. Secure the spray gun with the locking device.

8. Clean the gun body with a cleaning agent recommended by the lacquer

manufacturer. Clean the trigger locking device area.

9. Dry with a cloth or a blow gun.