76

Straightening the crankshaft

To assess straightness, the crankshaft must be support-

ed under main bearings 1 and 7 and main bearing 4

checked for out-of-round.

Below 0.2 mm

No straightening.

Between 0.2

Careful straightening, not more

and 0.7 mm

than necessary.

Above 0.7 mm

Replace crankshaft.

Straightening reduces fatigue resistance and should

therefore be avoided. The nitro-carburized bearing sur-

face has a tendency to crack at the fillets between the

bearing races and the webs.

Flywheel

Checking

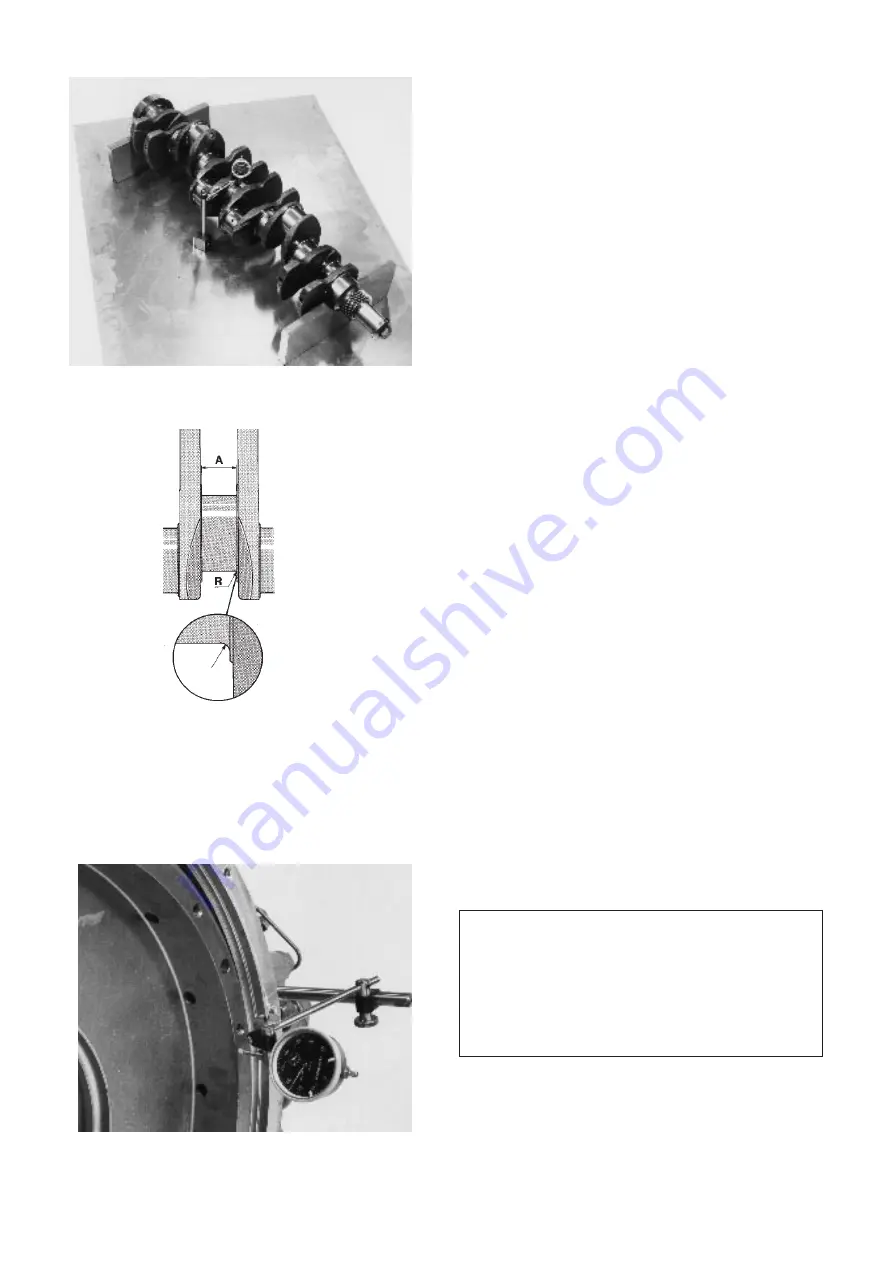

Crank the flyhweel to get max. throw. It must not

exceed 0.15 mm.

If the throw is greater than this, remove the fly-

wheel and check the contact surfaces for dirt or un-

evenness.

Machining

Damaged bearing surfaces should be lapped. If this is

not enough, replace the crankshaft or machine it. A ni-

tro-carburized crankshaft must be be ground more than

to second undersize, unless the nitro-craburizing treat-

ment is repeated. After treatment, bearing surfaces and

fillets should be lapped to a surface finish of 0.002 mm.

Grinding nicks or sharp edges are not permitted, as

they may cause fracture. The width measurement “A”

for the pilot bearing is particularly important. Refer to

“Specifications”.

After machining, thoroughly clean the crankshaft. Re-

check for cracks, using the magnetic power test method

and de-magnetize. Clean and flush all oil drillings.

NOTE!

It is most important that the fillets are ground to the

right shape and size. They should be between 3.75–

4.00 mm. Use a radial template for the measuring.

Measuring radius 150 mm

Содержание DH10A 245

Страница 1: ...Service Manual Buses Section 2 20 27 Engine DH10A 245 285 345 350 360 TP 16031 1 ...

Страница 31: ...30 Adjust in the supports on the lift unit as shown in the pictures below ...

Страница 59: ...58 Cylinder block crank mechanism ...

Страница 162: ...Volvo Bus Corporation TP 16031 1 English 2500 06 97 Printed in Sweden by Novum Grafiska AB 97 24296 Göteborg Sweden ...