71

Maintenance: Drive SX, DP-S

A

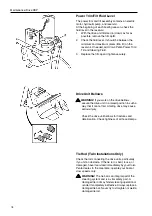

Oil draining and filling. DP-S drive

1.

Place drive unit in the run (down) position. Remove

propellers and mounting hardware. Please refer to

the "Propellers" chapter.

NOTE!

Removing DuoProp propellers require the use of

special tools.

2.

Remove the oil drain plug (B) (below propeller

shaft) and the oil level dipstick (A).

3.

Allow the drive unit to drain completely. Dispose of

used oil in accordance with any applicable

environmental regulations.

4.

To fill the drive unit, remove the three screws

securing the rear cover to access the oil level plug

(C). Remove oil level plug.

5.

Fill drive unit with oil through the oil drain plug

location (B). Fill slowly to purge air. The drive unit

is properly filled when the oil appears at the oil

level plug hole. For oil quality and capacity: Please

refer to the "Technical Data" chapter.

NOTE!

If unable to fill the drive unit through oil drain

plug (B), the drive can be filled by trimming it up a few

degrees and filling through the oil level plug (C).

6.

When filled to the proper level, install oil level

dipstick and oil level plug first to prevent

excessive oil loss, then the oil drain plug. Tighten

oil level and drain plugs securely. Reinstall oil level

plug, and place drive in the run (down) position.

Remove dipstick (A) and check oil level. Reinstall

dipstick and tighten securely.

7.

Install propellers. Install rear cover and tighten

screws securely. Check oil level with the dipstick,

oil must appear on the full range of dipstick. Add

oil if required through the dipstick hole.

NOTE

! If drive unit was filled through the oil level plug

(C), wait 15 minutes before checking oil with dipstick.

This will help ensure all air is purged from the oil cavity.

Leave dipstick (A) loose during waiting period.

Содержание D3-110i

Страница 1: ...OPERATOR SMANUAL D3 130A D3 160A D3 190A D3 110i D3 130i D3 160i D3 190i ...

Страница 103: ......

Страница 104: ...7745859 English 12 2005 ...