5 Application Examples

5.1 Motor Overload Protection

The thermal model used for motor overload in the MCD

500 has two components:

•

Motor windings: These have a low thermal

capacity and affects the short term thermal

behaviour of the motor. This is where the heat is

generated by the current.

•

Motor Body: This has a large thermal capacity and

affects the long term behaviour of the motor. The

thermal model includes considerations for the

following:

•

Motor current, iron losses, winding

resistance losses, motor body and

winding thermal capacities, cooling

during run and cooling at standstill.

•

The percentage of the rated capacity of

the motor. This sets the displayed value

for the winding model and is affected

by the motor FLC setting amongst

others.

NOTE

1-1 Motor FLC

should be set to the motor's rated FLC. Do

not add the overload rating as this is computed by the

MCD500.

The thermal overload protection used in MCD500 has a

number of advantages over the thermal relays.

•

The effect of fan cooling is accounted for when

the motor is running

•

The actual full load current and locked rotor time

can be used to more accurately tune the model.

The thermal characteristics of the windings are

treated separately from the rest of the motor (ie.

the model recognises that the windings have low

thermal mass and high thermal resistance).

•

The winding portion of the thermal model

responds very rapidly compared with the body

portion, meaning the motor can be run closer to

its safe maximum operating temperature while

still being protected from thermal damage.

•

The percentage of motor thermal capacity used

during each start is stored in memory. The starter

can be configured to automatically determine

whether or not the motor has sufficient thermal

capacity remaining to successfully complete

another start.

•

The memory function of the model means that

the motor is fully protected in “warm start”

situations. The model uses data from the real

time clock to account for elapsed cooling time,

even if control power has been removed.

The overload protection function provided by this model is

compliant with a NEMA 10 curve, but will provide superior

protection at low levels of overload due to the separation

of the winding thermal model.

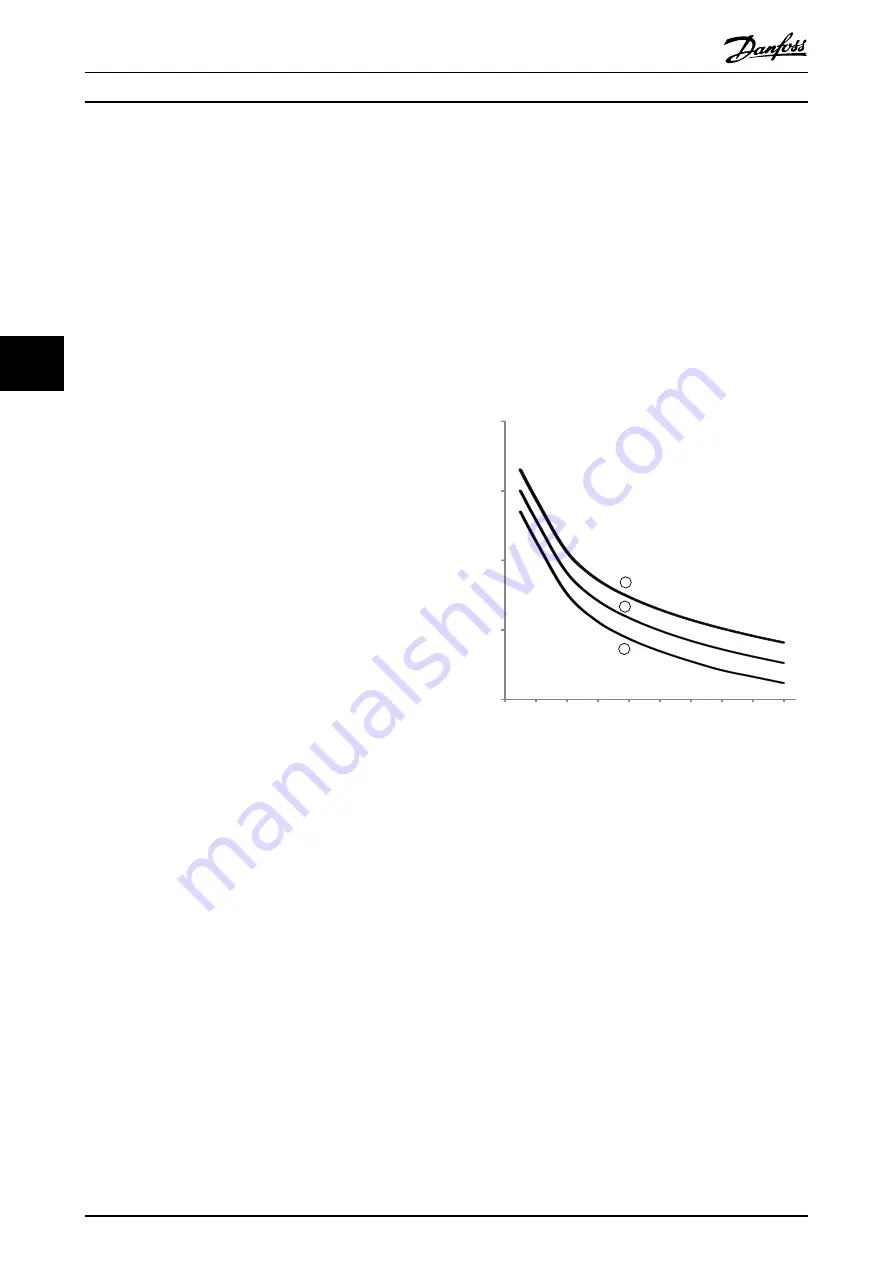

100

200

300

1

10

100

1000

10000

177HA596.10

Time in seconds to reach 100% of thermal model

Current (%motor full load current)

3

1

2

400

500

600

700

800

900 1000

Illustration 5.1

1.

MSTC

1

= 5

2.

MSTC

1

= 10

3.

MSTC

1

= 20

1

MSTC is the Motor Start Time Constant and is defined as

the Locked Rotor Time (in

1-2 Locked Rotor Time

) when the

Locked Rotor Current is 600% of FLC.

5.2 AAC Adaptive Acceleration Control

AAC Adaptive Acceleration Control is a new form of motor

control based on the motor's own performance character-

istics. With AAC, the user selects the starting or stopping

profile that best matches the load type and the starter

automatically controls the motor to match the profile. The

MCD 500 offers three profiles - early, constant and late

acceleration and deceleration.

Application Examples

MCD 500 Operating Instruction

30

MG17K402 - VLT

®

is a registered Danfoss trademark

5

5