8.1 Siting, installation

Siting conditions for open flue operation (appliance type B)

Type B

23

and B

33

In rooms where

air contamination from halogenated hydrocar-

bons or organosilicon compounds (e.g. siloxanes)

may occur,

such as hairdressing salons, printing shops, chemical cleaners, labo-

ratories, etc., the Vitodens may only be operated as a room sealed

system.

If in doubt, please consult us.

Never install the Vitodens in areas subject to very dusty conditions.

The installation location must be kept free from frost and must be

adequately ventilated.

Provide a condensate drain and a discharge pipe for the safety valve

in the installation room.

The max. ambient temperature of the system must not exceed

35 °C.

If these instructions are not observed, any consequential appliance

damage directly related to any of these causes is excluded from our

warranty.

a

When installing in Austria, observe all current safety regulations

as defined by ÖVGW-TR Gas (G1), ÖNORM, ÖVGW, ÖVE and

locally applicable standards.

Multi boiler systems with flue systems under negative pressure

Systems with several Vitodens with separate hydraulic connections

require a flue gas cascade suitable for negative pressure or individ-

ual flue gas routing for each boiler.

Installation room

Permissible:

■ Siting gas equipment on the same floor

■ Living space with interconnected room air supply

■ Ancillary rooms with interconnected room air supply (larders, base-

ments, utility rooms, etc.)

■ Ancillary rooms with vents to the outside: Ventilation air/extract air

150 cm

2

or 2 × 75 cm

2

each at the top and bottom of the same

wall, up to 35 kW

■ Attic rooms, but only with adequate minimum chimney height, acc.

to DIN 18160 – 4 m above inlet (negative pressure operation).

Not permissible:

■ Stairwells and communal hallways. Exception: In detached and

two-family houses of low height, top edge of floor in the top storey

< 7 m above ground level.

■ Bathrooms and toilets without outside windows with shaft ventila-

tion

■ Rooms where explosive or flammable materials are stored

■ Rooms that are ventilated mechanically or via individual duct sys-

tems to DIN 18117-1

Observe all local fire regulations.

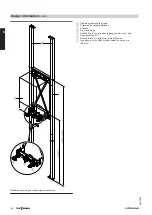

Connection on the flue gas side

The connection piece to the chimney should be as short as possible.

Therefore position the Vitodens as close to the chimney as possible.

The flue should be designed to be as straight as possible. If bends

are unavoidable, do not arrange these one after the other. The entire

flue gas path must be able to be checked and cleaned as required.

No special protective measures or clearances towards combustible

objects, such as furniture, packaging or similar, need to be taken/

observed. The surface temperatures of the Vitodens and the flue

system do not exceed 85 °C at any point.

For further details, see the technical guide on flue systems for the

Vitodens.

Extractors

When installing appliances with extraction to the outside (cooker

hoods, extractor fans, etc.), ensure that air extraction will not create

negative pressure inside the installation room. A return flow of flue

gases could result if the ventilation system and the Vitodens are

operated simultaneously. In such cases, install an

interlock circuit

.

Safety equipment for the installation room

Viessmann heat generators are tested and approved in accordance

with all safety regulations and are therefore fail-safe. Unpredictable

external factors may, in the rarest of cases, lead to the potentially

harmful escape of carbon monoxide (CO). For this case, we recom-

mend using a CO limiter.

Siting conditions for room sealed operation (appliance type C)

Type C

13x

, C

14(3x)

, C

33x

, C

43x

, C

53x

, C

63x

, C

83x

or C

93x

according to

TRGI 2018

The Vitodens can be installed for

room sealed

operation

independ-

ent

of the size and ventilation of the installation room.

Installation room

Suitable siting locations include:

■ Recreational rooms and other living spaces

■ Unventilated ancillary rooms

■ Cabinets (open at the top)

■ Recesses without compulsory clearance towards combustible

materials

■ Attic rooms (pitched attics and long panes) where the balanced

flue pipe can be routed directly through the roof

The installation room must be free from the risk of frost.

The max. ambient temperature of the system must not exceed

35 °C.

Provide a condensate drain and a discharge pipe for the safety valve

in the installation room.

Electrical interlocks for extractors (extractor hoods, etc.) are not

required with room sealed operation.

Connection on the flue gas side

The flue should be designed to be as short and straight as possible.

If bends are unavoidable, do not install them directly one after

another. The entire flue gas path must be able to be checked and

cleaned as required.

Since the flue pipe connection for room sealed operation is surroun-

ded by combustion air (coaxial pipe), no clearances towards com-

bustible materials need be maintained.

Ventilation air ducts with which oil or solid fuel boilers were previ-

ously used must not contain any sulphur or soot deposits on the

inner surfaces.

Sulphur and soot deposits cause operating faults.

If thorough cleaning is not possible, a balanced flue pipe must be

laid through the shaft. Alternatively, lay separate ventilation air and

flue gas pipes.

Viessmann accepts no liability for damages caused by a failure to

observe these stipulations.

Close off and seal any other connection apertures with appropriate

materials.

This does not apply to any cleaning or inspection apertures that are

provided with chimney cleaning covers and that are identified with an

appropriate test mark.

For further details, see the technical guide on flue systems for the

Vitodens.

Design information

94

VIESMANN

VITODENS

8

5853906

Содержание Vitodens 200-W B2HE

Страница 154: ...154 VIESMANN VITODENS...

Страница 155: ...VITODENS VIESMANN 155 5853906...