18

110332-02 - 6/22

PHTM II

Installation, Operating & Service Instructions

7

General Venting

(continued)

6. CPVC/PVC vent starter kits are available. Kits

include 30 in. (760 mm) CPVC pipe, 90° short

CPVC elbow, PVC coupling (vent terminal), 90°

short PVC elbow (air terminal), and 2 terminal

screens. Components in these kits are not

ULC-S636 listed and are therefore not usable in

Canada.

A. 2 in. kit: 107039-01

B. 3 in. kit: 107039-02

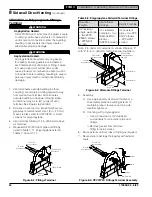

7. Allow for 3/8 in. (9.5 mm) of thermal

expansion per 10 ft. (3.0 m) of CPVC/PVC pipe. If

a straight run of pipe exceeds 20 ft. (6.0 m) and

is restrained at both ends, an offset or expansion

loop is required per Figure 7-15. If a straight

horizontal run of pipe exceeds 20 ft. (6.0 m) and

is restrained at one end with an elbow at the other,

ensure hanger or guide is not less than Y in from

elbow per Figure 7-15. Thermal expansion fittings

not permitted.

8. All air piping may be PVC.

9. Vent and air can be up-sized to 3 in. for

longer runs. If upsizing to 3 in. vent material, the

following is required:

A. 2 in. CPVC vent piece (max 12 in. 305 mm)

(field supplied).

B. 2 in. x 3 in. CPVC increaser (field supplied,

Lasco 9829-338, Spears 829-338C or IPEX

9829338 or equivalent).

C. 3 in CPVC/PVC vent starter kit (purchased

separately, see above).

D. Similar PVC fittings for air intake.

NOTICE:

Increaser must be installed in vertical

section of pipe. See Figure 7-13.

10. Cut pipe squarely and debur inside and

outside of pipe ends after cutting.

11. Dry fit all vent and air components before

cementing any joints.

12. Use field supplied primer and cement

appropriate for materials being joined. Follow

primer and cement instructions to join pipe

and fittings.

13. Clean all pipe ends and fittings with

appropriate primer before cement. Apply

primer to both pipe and fitting socket before

applying cement.

14. Boiler vent connector is gasketed. Lubricate

gasket with soapy water, insert pipe until it

bottoms out, and tighten clamp.

15. Boiler air connector in PVC socket fitting. Drill

7/32 in. (5.5 mm) hole in air connector. Drill

1/8 in. (3.2 mm) hole in air pipe to align with hole

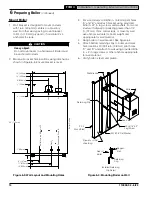

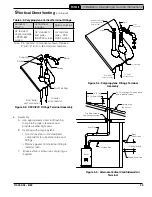

At least 30in. (760mm)

of CPVC pipe and one

CPVC elbow required

between boiler and PVC

vent piping.

PVC coupling may

be used to join CPVC

to PVC vent pipe.

Clamp

To vent

termination

From air

termination

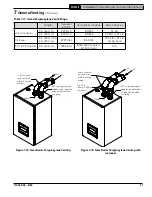

Max. 12in. (305mm)

2in. CPVC pipe

3in. X 2in. CPVC

Increaser

At least 30in. (760mm) of

CPVC pipe and one CPVC

elbow required between

boiler and PVC vent piping.

PVC coupling may

be used to join CPVC

to PVC vent piping.

3in. X 2in. PVC

Increaser

Clamp

Max. 12in. (305mm)

2in. PVC pipe

To vent

termination

From air

termination

Figure 7-12: Near Boiler CPVC/PVC Venting

Figure 7-13: Near Boiler CPVC/PVC Venting with

Increaser

Note: Length of 2 in. pipe is counted toward 30 in.

CPVC requirement.

in connector. Insert pipe into air connector and

use #10 x 1 in. sheet metal screw to secure. Seal

joint between air connector and pipe with RTV

silicone.

16. To the extent possible, slope horizontal air

piping towards outdoors.