22

EMR

3

- Truck Installations

EMR4 Terminal & Fueling Depot Installation

Installing The Interconnect Box (IB)

Figure 14. Display Head Cable Connections

Installing The Interconnect Box (IB)

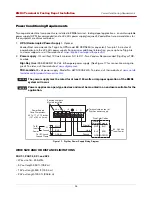

NATIONAL ELECTRICAL CODE COMPLIANCE

The following information is for general reference and is not intended to replace recommended National Electric

Code (NEC) procedures. It is important for the installer to understand that electrical equipment and wiring located

in Class I, Division 1 and 2 installations shall comply with the latest appropriate articles found in the National

Electric Code (NFPA 70) and the Automotive and Marine Service Station Code (NFPA 30A).

GROUNDING

Proper grounding of the EMR equipment is essential for several reasons. First, in a typical installation, grounding

prevents hazardous voltages from being present on the equipment. Secondly, grounding prevents the build-up of

static charge on the equipment. Either of these conditions could be very hazardous when in the proximity of

explosive mixtures found at fuel supply depots and terminals. Proper grounding requires that a very low impedance

connection be made to the earth. At the distribution panel, this is accomplished by means of a dedicated

conductor buried in the earth. It is imperative that all local, regional and national regulations are followed when

connecting to the grounding system.

ENS1J-489

ENS1J-489

-L00100

-L00100

BOURNS

BOURNS

VR ENCODER

VRENC

ODER

P/N

P/N

331884-001

331884-001

331933-001331933-001

I.S.

I.S.

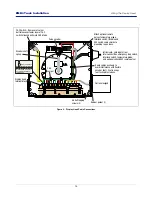

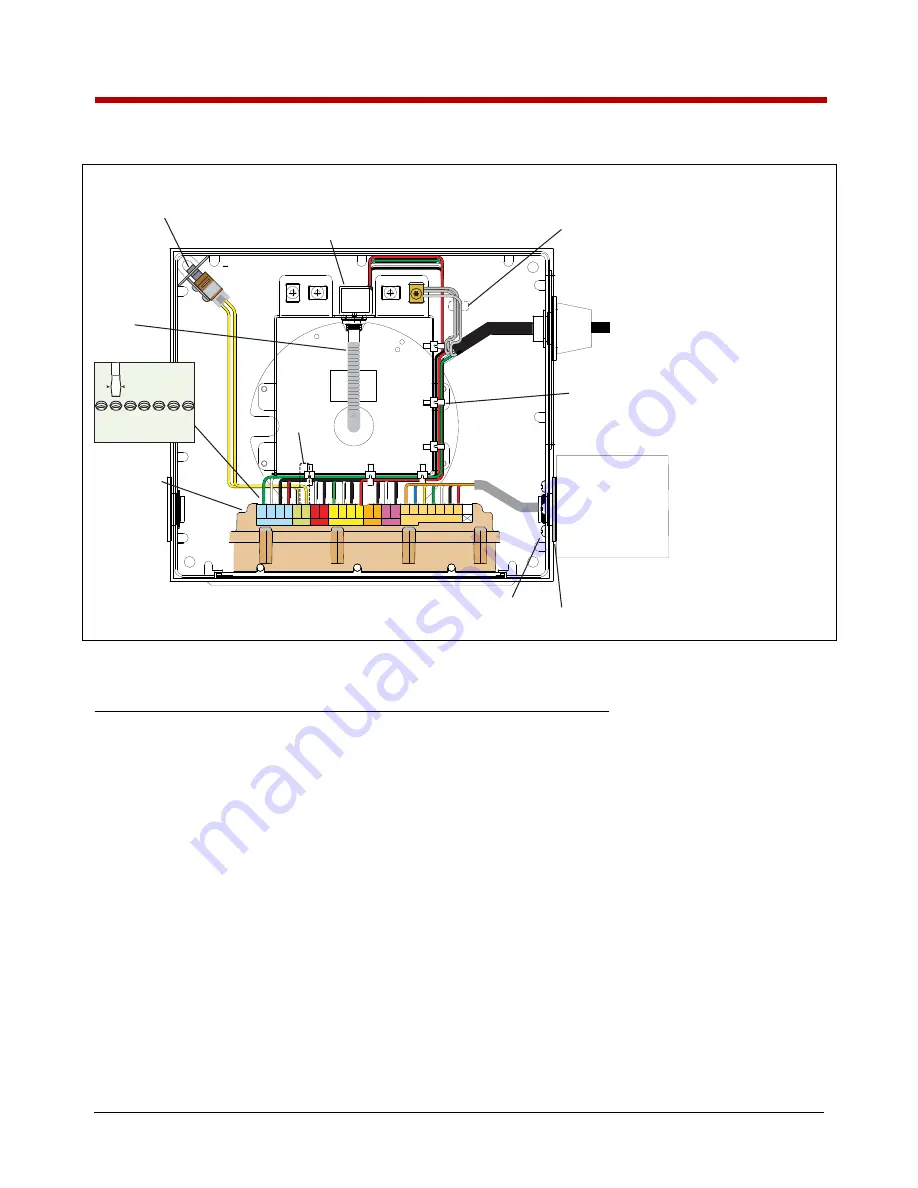

Intrinsically-safe inputs from

Interconnect Box, emergency stop switch,

interlock switch, temperature probe,

and optional series 8452 remote pulser

Route cables as shown to

avoid interference with flexible

encoder shaft. Use tie wraps

to attach cables to base.

Pulse encoder

Optional keypad

Encoder shaft

spring

C&C

Jumper

Display head

terminal block

Attach optional remote

pulser, temperature probe,

interlock switch, and

ESS switch cable shields to

grounding lug on base.

9/64” (3.5mm) max.

Note: Maximum screwdriver

size for attaching wires to

terminal block.

C&C Switch - Removal of corner

bolt releases actuator lever of C&C

switch allowing entry into C&C Mode

#6 Self tapping

screws (3)

Rubber gasket (1)

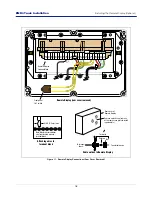

INTERCONNECT BOX

1000 RPM ENCODER

OPTIONAL KEYPAD

TEMP PRB

INTERLOCK

STOP SW

C & C SW

BLK

GND

RED

PWR

YEL

+

YEL

GND

WHT

+

BLK

GND

GRN

CHA

WHT

CHB

BLK

GND

RED

+5V

WHT

+

BLK

GND

WHT

+

BLK

GND

ORA

KP8

BLU

KP7

YEL

KP6

GRN

KP5

WHT

KP4

BLK

KP3

RED

KP2

NOT

USED

GRN

IB-A

WHT

IB-B