7 Parameters of Image Processing

18 / 41

7

Parameters of Image Processing

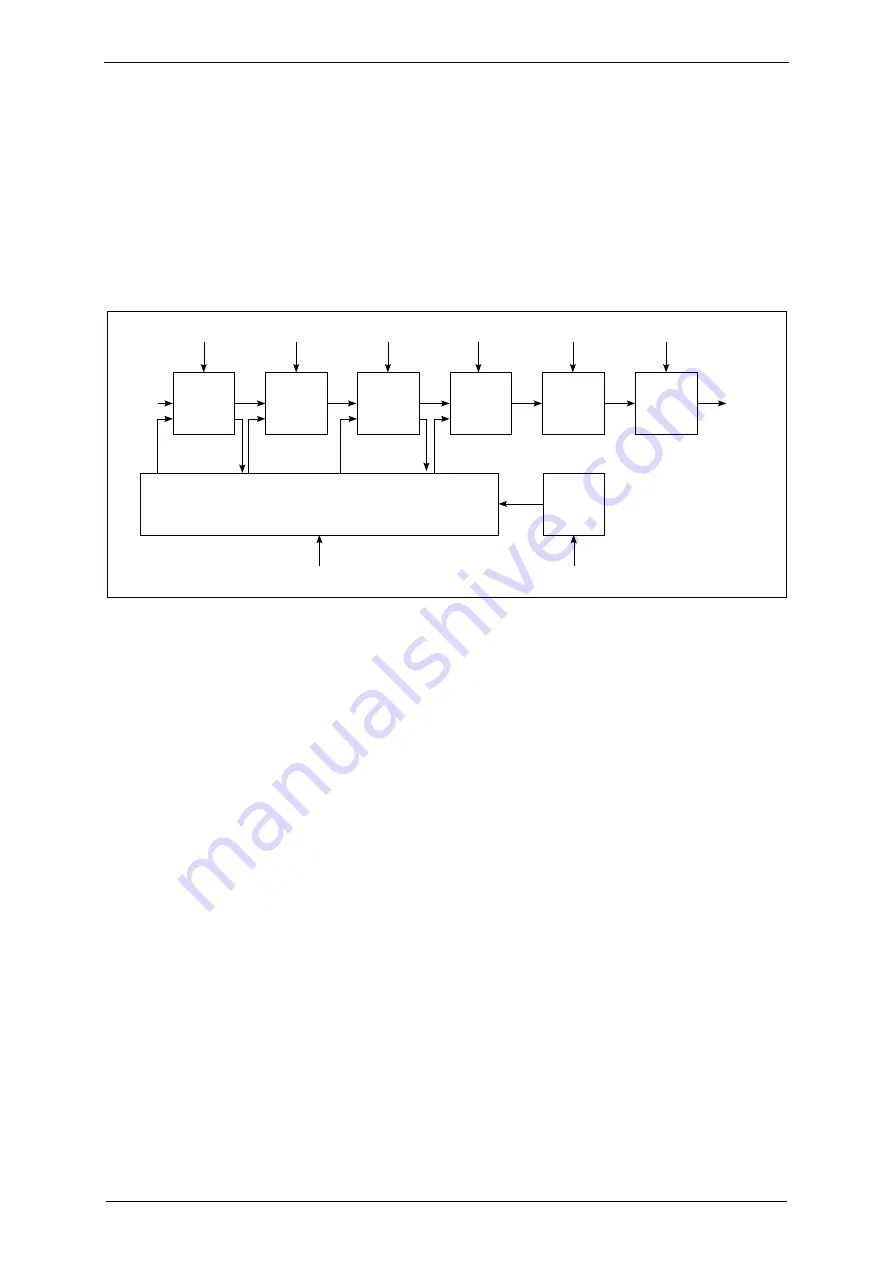

This chapter explains the function of the IRC-320 firmware. It is related to the individual modules of

image processing and shows in what way the user can control these modules via the serial Interface.

7.1

Image Processing Chain

Due to the fact that the uncorrected sensor image from the microbolometer sensor is very

inhomogeneous and that each sensor element has its own characteristic curve, an individual

adjustment of each pixel is necessary. The standard firmware of the IRC-320 contains a chain of

correction modules which undertake these tasks in real time.

LUT

Integrator /

Image Store

Two Point

Correction

Bad Pixel

Correction

Drift

Compensation

Output

(CL, GigE)

Input

(Camera

Raw Data)

E,J,K,N

F

m,n,o,p

H

Correction Data

Memory Access Module

S

(C)

(A,B)

(H/U,A,B)

(H/U)

Flash Memory

Access Module

A,B,C

Background

Subtr

Integrator /

Image Store

M,U

(U/H)

(U/H)

D,G

Each module can have various parameters which control the operation mode. In the sketch above and

as well within the text of this manual, these parameters are always marked by “

Courier

” font in

order to highlight them to be parameters (or commands) adjustable via the serial Interface.

For fast access all available correction data (e.g. reference images for the two point correction and bad

pixel correction control data) are copied from the non-volatile flash memory into a correction data

memory (SDRAM) when starting the camera. From this point the correction data is available for real-

time image correction. The image data from the camera head is shifted through the correction modules

and the corresponding correction data is applied. Some modules may also write new data back to the

correction memory – but currently only to the SDRAM and not to the non-volatile Flash memory.

The main correction modules are in detail:

1.

Two Point Correction

2.

Background Correction

3.

Bad Pixel Correction

4.

Drift Compensation

5.

Look Up Table (LUT)

With help of the

two point correction

(likewise “Gain Offset Correction”) the normally distinctive

underground structure of the microbolometer sensor can be equalized. The gain and the offset for each

pixel of the input image can be adapted to the set values on the basis of two reference images so that in

the optimum case no image structure is discernible.

The IRC-320 models feature an electromechanical shutter. In conjunction with the second correction

module in the chain – the

background correction

– the image quality can additionally be enhanced.

The shutter is closed to acquire a temporary background correction image. This image is subtracted

from the two point corrected image data to reduce the remaining fixed pattern noise.

VDS Vosskühler GmbH

IRC-320