ϭϵ

2. Lamp Status

The ECC will display each individual lamp status indicators in the form of Light Emitting Diodes (LEDs)

located on the display plate behind the window on the front door. The LEDs glow green when the lamp is

on. An extinguished LED indicates a possible lamp problem.

If the LED goes off, then it may mean that a lamp is no longer functioning. However, it may also indicate a

problem with the LED, the lamp’s corresponding ballast or a problem located within the lamp holder.

3. Runtime Monitoring

A digital non-resettable time meter has been integrated into the display plate of the ECC. This elapsed

runtime meter (ERTM) tracks operational hours on the system as a whole. It does not track individual lamp

run hours nor does it indicate when to service. The runtime meter is a tool to help track running hours to

help operators know when it is time to change lamps.

Operators should keep tracking logs in order to know when it is time to change lamps. Lamps need to be

changed every 10,000 hours (one year). UV lamps lose intensity over time and the system is designed to

provide proper dosage up to 10,000 hours of lamp life. Running the lamps more than 10,000 hours could

result in improper UV dosage.

b) Viewport

For models not equipped with a UV Monitor, a viewport has been installed on the UV chamber. The

purpose of a viewport is to safely verify lamp operation without the potential exposure to UV rays. The

viewport assembly consists of a viewport, sight glass, foam washer and an O-ring.

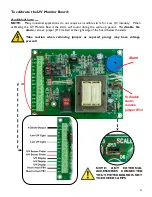

c) Lamp Out Alert (Optional)

Lamp out alert ballast(s) are used to connect an external control (PLC or SCADA) to the enclosure. The

Lamp Out Alert ballast contains relay contacts which provides a signal to the external control via lamp on /

lamp fault conditions. The enclosure has been wired with two red terminal blocks that is specifically for this

operation. An external control signal from a PLC or SCADA unit can be wired to the terminal blocks for a

closed circuit/open circuit condition for external control logic.

To operate, the circuit starts at one of the terminal blocks and runs to the incoming contact of the lamp out

relay of the first ballast and across the closed circuit contacts on the relay. From the outgoing relay contact

of the first ballast, the wires are fed to the incoming contact on the next ballast and across the closed circuit

contacts of the next ballast and so on to the last ballast (according to the number of lamps in the unit) and

fed back to the second red terminal block. In the normal operating state with all lamps lit, the circuit is

closed. If any of the lamps in the circuit fails, the corresponding lamp out relay will switch states, the chain

will be broken, and the circuit will be open. An external control signal from a PLC or SCADA unit can be

wired to the terminal blocks for a closed circuit/open circuit condition for external control logic.

Warning!

Control signal may not exceed 32V AC, 50V DC, 50mA current

Содержание LEOPARD UV Series

Страница 2: ......

Страница 6: ......

Страница 35: ......

Страница 40: ...Replacement Parts List Electrical Enclosure Leopard Series Short Long Chambered Systems...

Страница 43: ...Model Number __________ Serial Number __________...

Страница 44: ...d Z s K D s s hs Y W K K Z K Z K t W W Z s s hs D Z s Z hs hs...

Страница 46: ...EKd...

Страница 47: ......