7

must be inserted through the lid of the left (wash) pail. Models with a Manual Rinse feature have

another tube which needs to be inserted through the lid of the right (rinse) pail.

•

Move the pails into the cabinet and re-connect the Suction Pipe of the left pail to the Drain Valve.

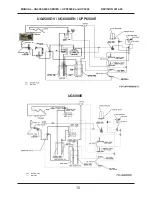

For Units Where Pails are Included (see below and next page)

SOLVENT PAIL SETUP (continued)

For Units Where Pails are Included (see picture on previous page)

PLASTIC PAILS

•

Disconnect the Suction Pipe (if not already disconnected) from the Drain Valve (make sure it is in

the closed, horizontal, position) by pressing the button and pulling down.

•

Bring out PAIL NO.2 and remove the Suction Pipe (and Manual Wash Suction Tube if there is

one).

•

Bring out PAIL NO. 1 and remove the Caps from both pails.

• Fill PAIL NO. 2 with 3 about Gal (11 L) of clean solvent.

•

Fill PAIL NO. 1 with 5 about Gal (19 L) of clean solvent (about 1“ below the overflow pipe).

•

Re-install the Caps onto the pails (the one with the tube goes on PAIL NO. 2).

•

Put PAIL NO. 1 and the Riser back into the cabinet.

•

Re-insert the Suction Pipe (and Manual Wash Suction Tube if there is one) into PAIL NO. 2

•

Put PAIL NO. 2 back into the cabinet and re-insert the Overflow Pipe.

•

Re-connect the Suction Pipe to the Drain Valve by pressing the button and pushing up.

•

Turn the Drain Valve handle to the open position (vertical) and close the Door.

METAL PAILS - OPTIONAL (see picture below)

•

Place two pails in front of the unit with the labels facing you and remove caps from both pails.

•

Pour 5 Gal (19 L) of solvent into Rinse Solvent Pail and 3 Gal (11 L) into Wash Solvent Pail.

•

Turn Handle of Drain Valve to closed (horizontal) position and disconnect the Suction Pipe (if not

already disconnected) by pressing the button and pulling down.

•

Bring Rinse Pump and, if present, Manual Wash Suction Tube to outside of Base Cabinet.

•

Insert the Suction Pipe into the Wash Pail and the Rinse Pump into the Rinse Pail.

•

If present, insert Manual Wash Suction Tube into the hole of Rinse Solvent Pail.

SOLVENT PAIL SETUP - METAL PAILS

MANUAL - UG4000-6000 UPP6500E and UP6000

REVISION 2014-09