Maintenance

g012785

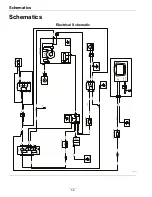

Figure 32

1.

Positive (+) cable on discharged battery

2.

Positive (+) cable on booster battery

3.

Negative (–) cable on the booster battery

4.

Negative (–) cable on the engine block

5.

Booster battery

6.

Discharged battery

7.

Engine block

4.

Connect the other end of the positive cable to the

positive terminal of the booster battery.

5.

Connect the black negative (–) cable to the other

terminal (negative) of the booster battery.

6.

MAKE THE FINAL CONNECTION ON

THE ENGINE BLOCK OF THE STALLED

VEHICLE (NOT TO THE NEGATIVE POST)

AWAY FROM THE BATTERY. STAND BACK.

7.

Start the vehicle and remove the cables in the

reverse order of connection (the engine block

(black) connection is the first to disconnect).

Check for Loose Hardware

Service Interval: Before each use or daily

1.

Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2.

Visually inspect machine for any loose hardware

or any other possible problem. Tighten hardware

or correct the problem before operating.

Service Air Cleaner

Service Interval: Before each use or

daily—Check air cleaner;

replace if dirty. (May need

more often under severe

conditions.)

Every 100 hours—Replace

the dual element air

cleaner element.

1.

Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2.

See the Engine Owner's Manual for maintenance

instructions.

Change Engine Oil

Service Interval: After the first 5 hours

Every 100 hours (May

need more often under

severe conditions.)

1.

Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2.

Drain oil while engine is warm from operation.

3.

The oil drain plug is located on the left side of

the engine.

Place pan under machine to catch oil. Remove

drail oil plug to open and allow oil to drain and

reinstall valve when complete.

4.

Clean around oil fill cap and remove cap. Fill to

specified capacity and replace cap.

5.

Use oil recommended in the

Check Engine Oil

Level

section.

Do Not

overfill. Start the engine

and check for leaks. Stop engine and recheck oil

level.

6.

Wipe up any spilled oil from engine deck

mounting surfaces.

Check Hydraulic Oil and

Tank Level

Service Interval: Every 40 hours

1.

Stop engine and wait for all moving parts to stop,

and remove key. Engage parking brake.

2.

Remove the knee pad.

3.

Clean area around oil overflow tank and remove

cap. Oil level should be between the “add” and

“full” marks on the tank bracket (see Figure 33);

if not, add hydraulic oil. Replace tank cap and

tighten until snug. Do Not overtighten.

45

Содержание Z-SPRAY JUNIOR Series

Страница 1: ...Z SPRAY JUNIOR SERIES For Serial Nos 411 294 212 Higher Part No 4505 818 Rev A...

Страница 60: ...Notes 60...

Страница 61: ...Notes 61...

Страница 62: ...Service Record Date Description of Work Done Service Done By 62...

Страница 63: ...63...