25

5. TSC Console

TSC Console is a management tool combining the Printer Management, Diagnostic Tool, CommTool and Printer Webpage settings,

which enables you to adjust printer’s settings/status; change printers’ settings; download graphics, deploy fonts, graphics, label

templates or upgrade the firmware to the group of printers, and send additional commands to printers at the same time

.

※

Printer firmware version before A2.12 will only use 9100 Port as command port; Printer firmware after A2.12 will use

6101 Port as command port.

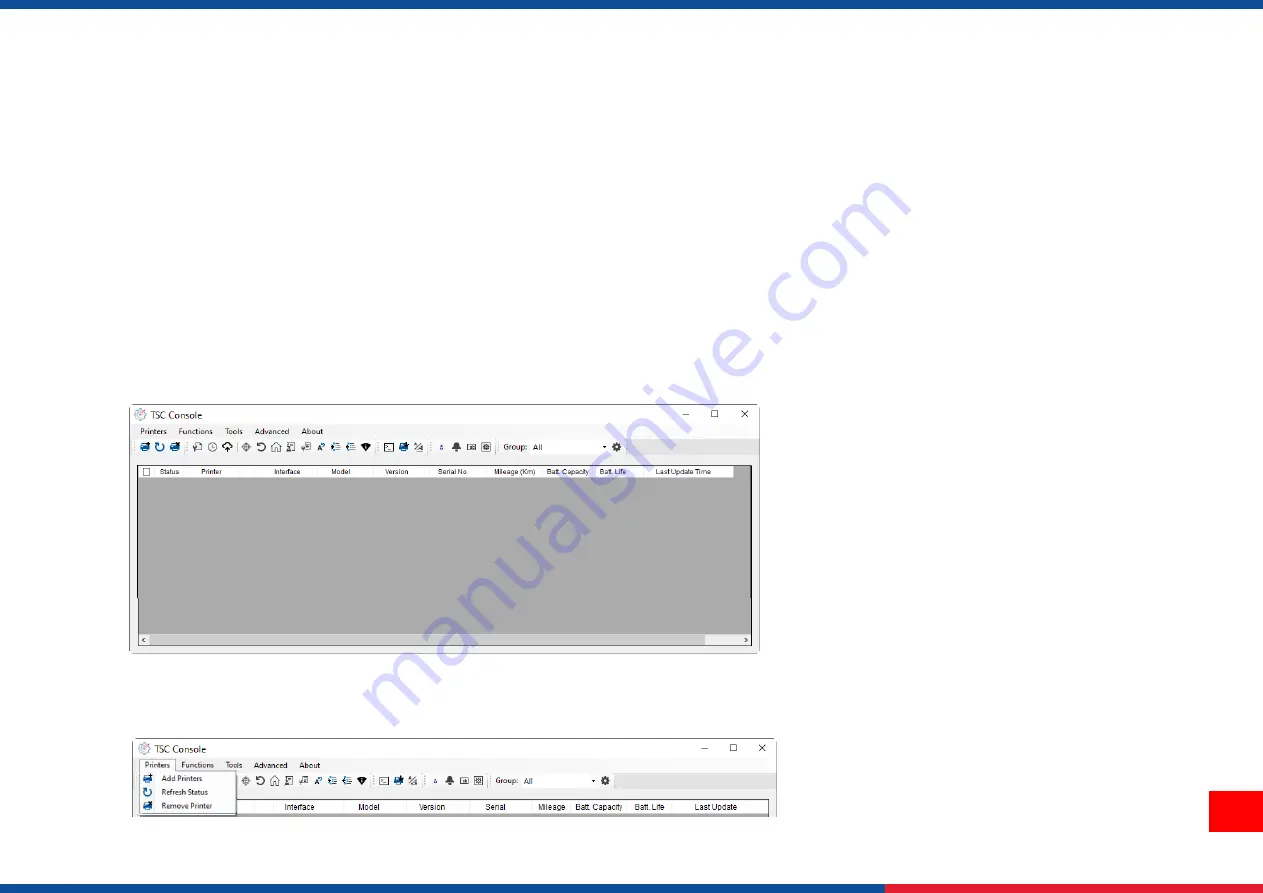

5.1 Start TSC Console

1.

Double click TSC Console icon to start the software.

2.

Manually add the devices by clicking

Printer > Add Printers

.

Содержание TTP-244 Pro Series

Страница 40: ...36 9 Revise History Date Content Editor ...

Страница 41: ......