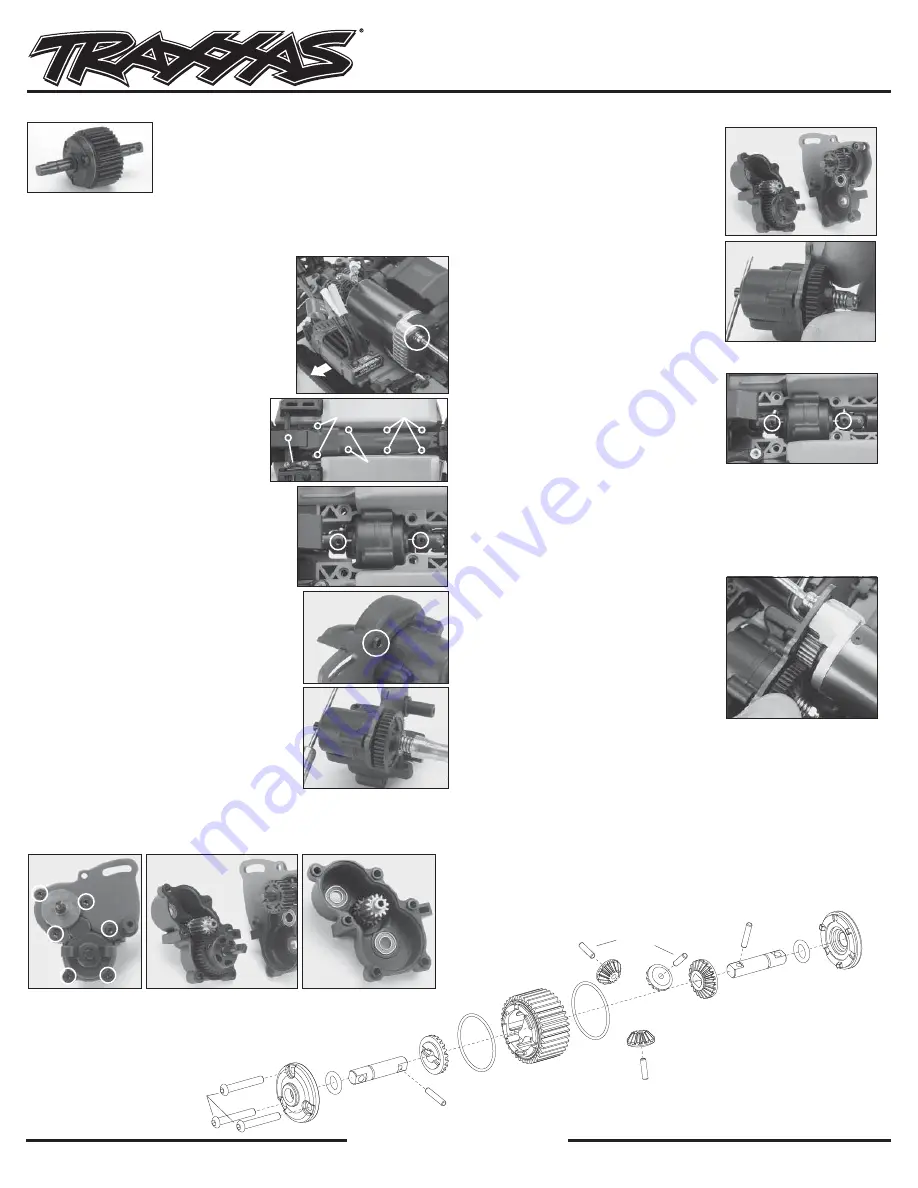

1/16th Scale Slash and E-Revo Center Differential Kit

www.TRAXXAS.com

Traxxas, 6200 Traxxas Way, McKinney, TX 75070, Phone: 972-265-8000, Fax: 972-265-8011, e-mail: [email protected]

KC1896-R00 130613

Covers Part #7014

Note:

This 1/16-scale Slash/E-Revo center differential

comes assembled with 50K differential fluid and is

tunable by changing fluid thickness. The 50K fluid is

recommended for best all-around performance.

Tools needed:

1.5mm hex wrench, 2.0mm hex wrench,

2.5mm hex wrench, Traxxas 4-way nut driver

Remove transmission from the vehicle:

1. Disconnect the three motor wires from

the ESC; then, open the right side battery

compartment door to slide the ESC out away

from the motor. Remove the silver 3x8mm

cap head screw from the motor (A). Pull the

motor toward the rear to remove it from the

chassis.

Note:

The ESC only needs to be shifted

over far enough to remove the motor.

2. Turn the chassis upside down to access

the center skid plate. Remove the

screws from the center skid plate, as

indicated in photo B: (4) 3x8mm button

head screws, (2) 3x10mm button head

screws, (2) 3x15mm button head screws,

and (1) 3x12mm countersunk screw from the

steering bell crank. Remove the center skid

plate from the chassis.

3. Remove each screw pin from the front and

rear output yokes exiting the transmission

(C). Pull the yokes away from the transmission

to release the transmission from the top of

the chassis.

Install the differential into the transmission:

1. Remove the gear cover by removing the 2x6mm

cap head screw from the motor plate (D).

2. Insert a 1.5mm hex driver into the hole in

the input shaft and use a 4-way nut driver to

remove the spur gear and slipper spring from

the input shaft of the transmission (E).

3. Remove the (6) 2x12mm countersunk screws

from the transmission case (F); then, separate

the transmission halves to access the output

gear and shaft assembly (G). Remove the output

gear and shaft assembly (H).

4. Insert the center differential in the

transmission case half (I). Reconnect the

transmission halves together, making sure

the gears are aligned correctly. Secure

the transmission halves together with (6)

2x12mm countersunk screws.

5. Slide the spur gear onto the input shaft

along with the slipper spring (J); then,

thread the 3.0mm nylon lock nut onto

the shaft. Adjust the slipper nut to allow

the spur gear to slowly spin on the shaft

while the shaft is locked with the 1.5mm

hex wrench.

Note:

This adjustment is

approximately ¾-turn from snug (spring

collapsed).

Reinstall the transmission

1. Set the transmission back on the chassis.

Attach the center drive shaft yokes to the

output shafts. Secure the output yokes

with the (2) screw pins (K).

2. Attach the center skid plate to the

chassis; then, secure it with the same

screws.

Note:

The front end of the center skid plate must fit under the front

skid plate before securing the 3x12mm countersunk steering bell crank screw.

3. Slide the motor/motor mount assembly back onto the motor plate. Set

the gear mesh (L), and then secure the motor with the silver 3x8mm cap

head screw.

Setting gear mesh:

Loosen the motor

screw just enough to shift the motor on

the motor plate. Press the pinion gear

up against the spur gear until the gear is

hard to turn. Gently slide the pinion gear

away from the spur gear until there is just

a small amount of play between the two

gears, and then tighten the motor screw

(L).

4. Reconnect the motor wires; then, slide

the ESC back toward the motor until it stops. Close the right side battery

door; then, secure the gear cover to the motor plate with the same

2x6mm cap head screw.

A

C

B

D

E

I

J

F

G

H

If you have questions or need technical assistance, call Traxxas at

1-888-TRAXXAS

(1-888-872-9927) (U.S. residents only)

3x12mm

3x12mm

3x15mm

3x15mm

3x10mm

3x10mm

3x8mm

3x8mm

7014

2x13 BCS

7014

7014

7014X*

7014

7014X*

7014

7014X*

7014

7014X*

7014

7014X*

7014

7014X*

7014

7014

7014

7014

7014

1.5x6 PIN

7014

1.5x6 PIN

7014

1.5x8 PIN

7014

1.5x8 PIN

K

L

*

Note:

7014X is a rebuild kit that contains

the differential O-rings and gear covers.