Installation

RT-SVX24J-EN

49

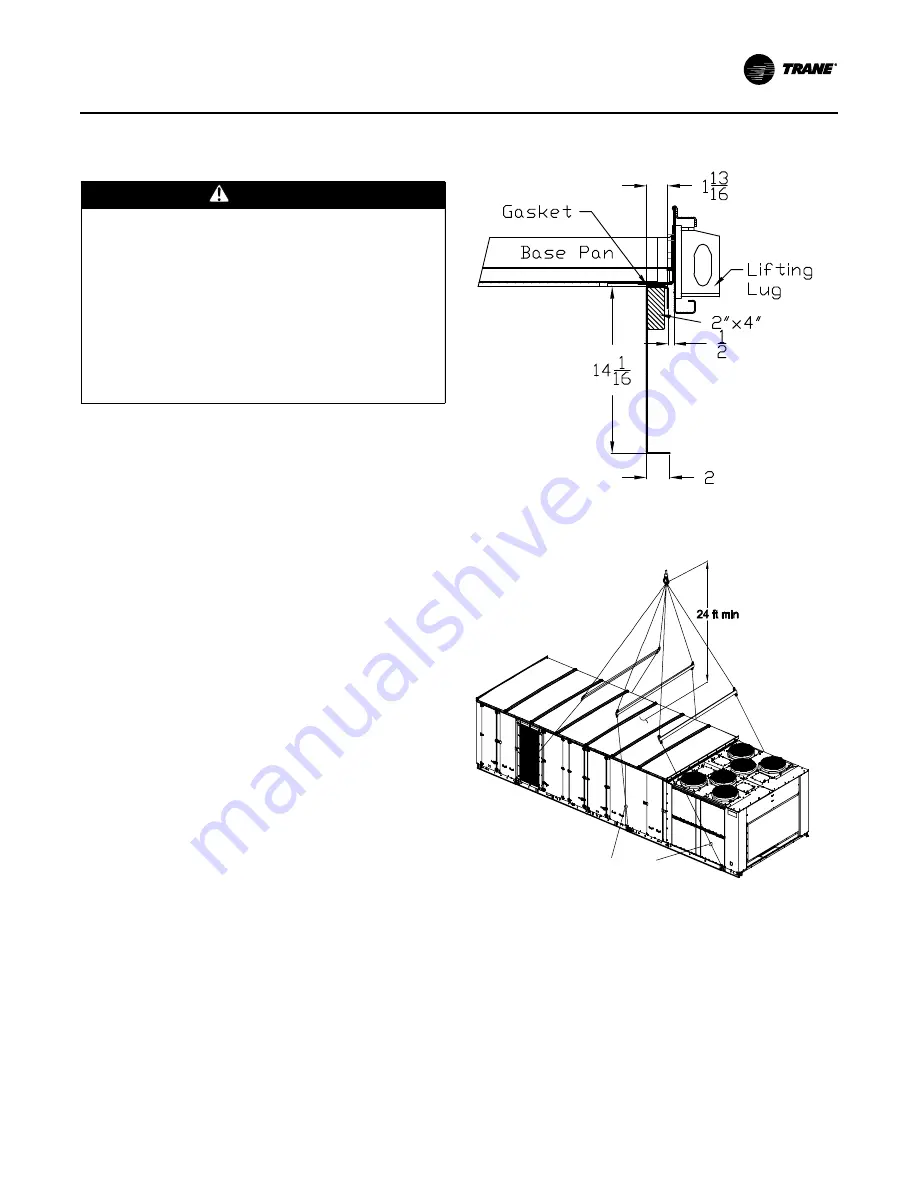

Unit Rigging and Placement

1. To configure the unit Center-of-Gravity, utilize TOPSS

or contact the local Trane sales office.

2. Attach adequate strength lifting slings to all lifting lugs.

The figures beginning with

Figure 20, p. 49

show the

minimum distance between the lifting hook and the

top of the unit and illustrate the installation of spreader

bars to protect the unit and to facilitate a uniform lift.

Table 12, p. 42

lists typical approximate minimal unit

operating weights. To determine additional

component weight, see

Table 13, p. 42

3. Test lift the unit to ensure it is properly rigged and

balanced, make any necessary rigging adjustments.

4. Lift the unit and position it over the curb and pedestal.

(These units have a continuous base rail around the air

handler section which matches the curb.

5. Align the base rail of the unit air handler section with

the curb rail while lowering the unit onto the curb.

Make sure that the gasket on the curb is not damaged

while positioning the unit. (The pedestal simply

supports the unit condenser section)

A cross section of the juncture between the unit and the

roof curb is shown in

Figure 19

.

WARNING

Heavy Objects!

Ensure that all the lifting equipment used is properly

rated for the weight of the unit being lifted. Each of the

cables (chains or slings), hooks, and shackles used to

lift the unit must be capable of supporting the entire

weight of the unit. Lifting cables (chains or slings) may

not be of the same length. Adjust as necessary for even

unit lift. Other lifting arrangements could cause

equipment or property damage. Failure to follow

instructions above or properly lift unit could result in

unit dropping and possibly crushing operator/

technician which could result in death or serious injury.

Figure 19. Curb cross section

Figure 20. Typical unit rigging—one-piece unit with three

lifting lugs per side

(a)

One piece unit with three

lifting lugs per side

Turnbuckle or

Chain Adjustment

for each lug

Содержание SEHJ090-162

Страница 40: ...Dimensional Data 40 RT SVX24J EN Figure 13 Evaporative condenser water connection locations RIGHT SIDE VIEW ...

Страница 48: ...Installation 48 RT SVX24J EN Figure 18 Ductwork conversion ...

Страница 58: ...Installation 58 RT SVX24J EN Figure 36 5 Connected tubes 6 install panels Connected tubes 5 6 ...

Страница 75: ...Installation RT SVX24J EN 75 Figure 51 Hot water coil piping Figure 52 Steam coil piping ...

Страница 87: ...Installation RT SVX24J EN 87 Figure 57 Typical field wiring diagram for 90 to 162 ton CV control options ...

Страница 89: ...Installation RT SVX24J EN 89 Figure 59 Typical field wiring diagram for 90 to 162 ton VAV control options ...