190

RT-SVX36G-EN

Maintenance

Always consult local codes for water treatment and waste water removal requirements. Consult a

water treatment expert for water analysis and chemical treatment methods and recommendations

for specific applications.

If deemed necessary after consultation with local water experts, there are various means of water

treatment available which can be field installed.

Copper Coil Cleaning

With proper water treatment, scale should not form on the coil, and coil cleaning should not be

required. In the event that scale starts to form on the coil, it is imperative that it is removed

immediately. The formation of scale can greatly reduce the performance and reliability of the coil.

To remove any scale that forms use only 100% citric acid based cleaners such as “Now” or other

pure citric acid products.

Important:

Do not use HCL-, muriatic acid, or ammonia-based cleaners as they can adversely

affect copper.

Do not power wash condenser fan. See RT-SVB83*-EN for additional information.

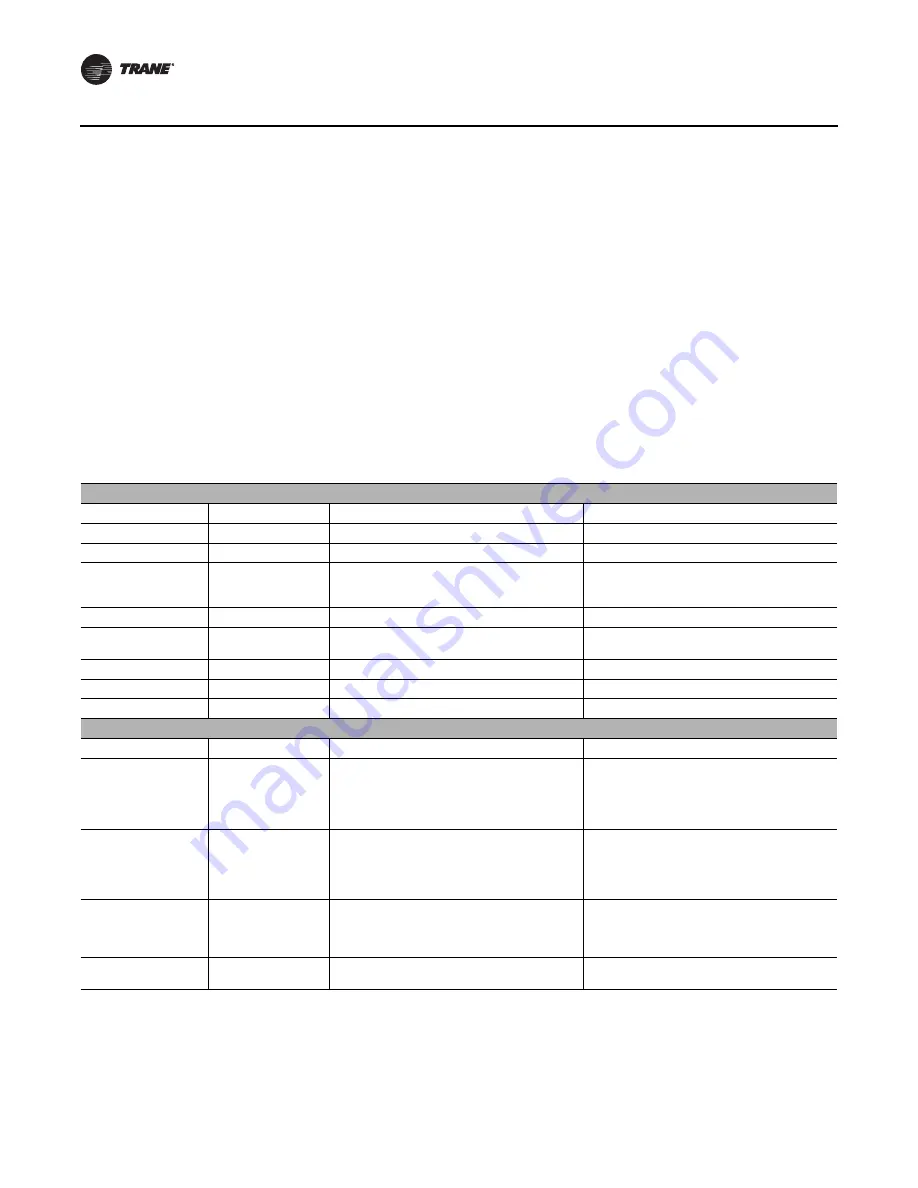

Table 70. Evaporative Condenser Models—Maintenance and Troubleshooting

Maintenance Schedule

Component

Action

Frequency

Comments

Fan Motor

None Required

Non-grease bearings

Sump Pump

Inspect/Clean

1 – 2 times per year

Clean inlet openings to pump

Sump

Inspect/Clean

1 – 2 times per year depending on water

hardness and unit run time

Sump can be drained and hosed out using hose

bib provided at water fill solenoid valve.

Vacuuming scale out is an alternate method.

Sump Float Switch

Inspect

1 – 2 times per year

Float should be free for full float travel

Sump Float

Make Up Valve

Inspect for proper

water level

1 – 2 times per year

Spray Nozzles

Inspect/Clean

1 – 2 times per year

Inspection through access panel

Conductivity Sensor

Inspect/Clean

1 – 2 times per year

Clean sensor to ensure accurate readings

Conductivity Controller

Inspect/Recalibrate

1 – 2 times per year

Recalibrate controller

Troubleshooting

Component

Problem

Check

Fix

Fan Motor

Does not run

Condenser Fan Relay closure and control voltage

indicating a call from compressor control panel

for the condenser fan to operate. Sump Pump

Overload Trip. Fan Motor Overload Trip. Fan fuse

trip.

Check each motor overload and reset if

necessary. Check amp draw for each leg.

Sump Pump

Does not run

Sump Pump Overload Trip Low Water Level or

faulty float switch. Unit in ‘Dry Mode’ Operation

Reset – check amps on each leg to determine if

faulty motor. Check and clean debris around float

switch. Check Ambient thermostat setting and

mode of operation (close on rise). See section 2

for T’stat setup instructions.

Sump Pump

Low Flow

Pump may be operating backwards or impeller

inlet may be slightly blocked.

Change pumping direction by changing any two

legs to the pump motor. Disconnect Power and

remove pump to inspect for possible impeller

obstruction.

Spray Nozzle

Dry area on coil

Check for proper spray pattern over each

quadrant.

Remove debris from clogged nozzle.

Содержание IntelliPak SAHL Series

Страница 47: ...RT SVX36G EN 47 Installation Figure 16 Unit rigging Figure 17 Typical unit base and roof curb cross section...

Страница 65: ...RT SVX36G EN 65 Installation Figure 30 Hot Water Piping 90 130 Ton Figure 31 Steam Coil Piping 20 36 Ton...

Страница 86: ...86 RT SVX36G EN Installation Figure 38 Field connection diagram notes for 20 89 ton CV or VAV applications...

Страница 87: ...RT SVX36G EN 87 Installation Figure 39 Typical field wiring diagram for 20 89 ton VAV control option 2307 9177...

Страница 88: ...88 RT SVX36G EN Installation Figure 40 Typical field wiring diagram for 20 89 ton VAV control option...

Страница 173: ...RT SVX36G EN 173 Startup Checklists Figure 88 Dry bulb changeover map...

Страница 175: ...RT SVX36G EN 175 Maintenance Figure 89 Unit internal fuse replacement data for air handling units...