6

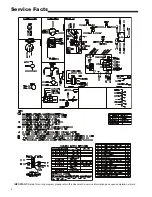

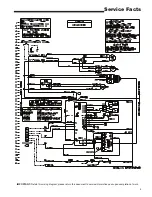

Service Facts

Sequence of Operation

Operation of the unit heating or cooling cycles is controlled

by the setting of the comfort control. Once the comfort control

is set to either HEAT or COOL, unit operation is automatic. A

fan setting on the comfort control also provides for continuous

operation of the indoor fan when desired. The fan, when set

to ON provides continuous operation, while AUTO provides

operation during the heating or cooling cycles. CONTINU-

OUS fan mode during COOLING operation may not be ap-

propriate in humid climates. If the indoor air exceeds 60%

relative humidity or simply feels uncomfortably humid, it is

recommended that the fan only be used in the AUTO mode.

Heating Cycle

Comfort Control call for heat ( 2-stage thermostat)

Call for 1st stage only:

(R) and (W1) thermostat contacts close signaling the control

module (IGN) to run its self-check routine. After the control

has verified that the pres sure switch (PS) contacts are open,

the limit switch (TCO) contacts are closed, and the flame

rollout (FL) switch is closed, the induced draft blower (CBM)

will be energized on high speed for approximately 5 seconds.

After the induced draft blower (CBM) has come up to speed,

the control will verify that the pressure switch (PS) contacts

are closed and switch the induced draft blower to low speed

for 20 second prepurge. The gas valve (GV) is ener gized

in the first stage to permit gas flow and the spark igniter (IP)

is energized. The flame detector (FD) confirms that igni tion

has been achieved within the 7 second trial period.

As the flame detector confirms that ignition has been

achieved the delay to indoor fan on period begins timing and

after approximately 45 seconds, the indoor blower motor

(IDM) will be energized at low speed and will continue to run

during the heating cycle.

Call for 2nd stage after 1st stage:

(R) and (W2) thermostat contacts close signaling a call

for second stage heat. The induced draft motor (CBM) is

energized on high speed and the gas valve on second stage.

After approximately 30 seconds the control energizes the

indoor blower on high speed.

2nd stage satisfied, 1st stage still called:

(R) and (W2) opens, the induced draft blower is reduced to

low speed the gas valve is reduced to first stage. After about

30 seconds the indoor blower motor is reduced to low speed.

1st stage satisfied:

(R) and (W1) opens, the gas valve (GV) will close. The

induced draft blower (CBM) will be de-energized after

approximately 5 seconds postpurge. The indoor blower

motor (IDM) will continue to run for the fan off period (field

selectable 60 or 90 seconds [by jumpers]), then will be de-

energized by the control module.

Comfort Control call for heat (1-stage Comfort Control)

(R) and (W1/W2) (jumped) thermostat contacts close

signaling a call for heat. 1st stage sequence of operation

remains the same as above. 2nd stage heat has a 10 minute

delay from the time of 1st stage ignition.

Comfort Control satisfied:

Safety Sequences

This product is equipped with safety devices to protect against

abnormal conditions.

The temperature limit switch (TCO) is located on the blower

barrier, and can be accessed through the blower compart-

ment. This automatic reset device protects against exces sive

supply air temperature. If this device opens, the gas valve

is immediately closed and will not permit operation until the

limit switch closes.

The rollout switch (RO) is located in the gas compartment

near the inlet of the burners. This is a manual reset device

designed to protect against any form of flame rollout. If this

device is opened the gas valve is immediately de-energized

and the control (IGN) will lockout the system. The rollout switch

(RO) must be reset before operation is allowed to continue.

The pressure switch (PS) is located in the upper right side

of the gas compartment. This automatic device assures

adequate combustion air pressure. If pressure against the

induced draft blower outlet becomes excessive, the pressure

switch will react and shut off the gas valve, until acceptable

combustion pressure is again available.

If the control (IGN) does not sense flame within the first trial

for ignition period, the gas valve will be de-energized. The

control (IGN) will initiate a 60-second interpurge. Following

the interpurge, the control will perform a second ignition

attempt. If the second try is not successful, the control will

start another 60-second interpurge. After the interpurge, a

third attempt will be tried. If the third try is not successful, the

control will lock out.

If loss of flame occurs during a heating cycle, the control

(IGN) will close the gas valve and cycle through the ignition

trial as stated above.

If control lock out occurs, the control (IGN) will retry a complete

ignition sequence in 1 hour.

The control (IGN) can be reset by removing power to the unit

or by turning the thermo stat from ON to OFF for approximately

three seconds, then back ON.

Cooling Cycle

With the comfort control set to COOL and the fan set to

AUTO, the com pressor contactor (CC) and the indoor fan

motor (IDM) are energized.

The energized compressor contactor (CC) completes the cir-

cuit to the compressor (CPR) and a secondary circuit to the

outdoor fan motor (ODM). If the compressor safety controls

are closed, the compressor (CPR) will operate with the outdoor

fan motor (ODM). The indoor fan motor (IDM) will operate.

The thermostat will continue to cycle the compressor and

fans to maintain the desired temperature.

With the comfort control fan set to ON, the indoor fan mo-

tor (IDM) will continue to run regardless of compressor and

condenser fan operation.

(R) and (W1/W2) (jumped) contacts open signaling the control

module to close the gas valve and de-energize the induced

draft blower after approximately 5 second postpurge. The I.D.

blower motor will continue to operate at the current speed for

60 or 90 seconds after the flames are extinguished .

Содержание 4YCY4036B-SF-1H

Страница 9: ...9 Service Facts...

Страница 12: ...Trane 6200 Troup Highway Tyler TX 75707 01 13...