8. Purge unit.

9. Check oil pressure 18–22 psi.

Run

Top View

Change

Filter

Drain

General Lubrication

The only chiller component that requires periodic lubri-

cation is the external vane linkage assembly and Rotary

oil valve. Lubricate the vane linkage shaft bearings and

rod end bearings as needed with a few drops of light-

weight machine oil.

Consider placing a bead of silicon caulk around the top

of the oil filter shut off valve if the chiller is located in a

wet, dusty or corrosive environment.

The CenTraVac inlet guide vane tang operators should

be serviced annually with R-123 and R514A compatible

grease. Use only Trane approved R-123 and R514A com-

patible grease:

LUB00033 (16 oz. standard grease gun cartridge)

LUB00063 (3 oz. mini grease gun cartridge)

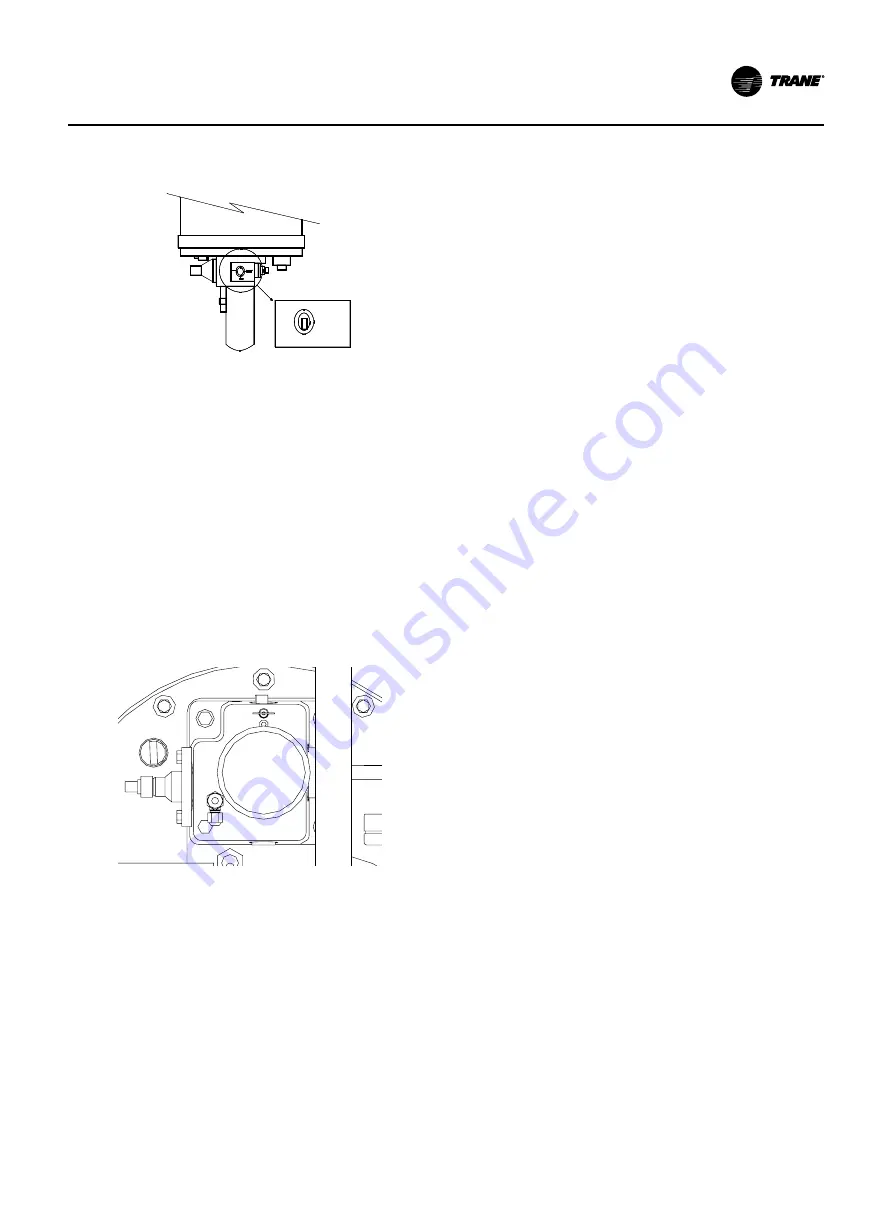

Service for the 1st Stage Tang Operator

All Units Except Extended Capacity Chillers with

1470 or 1720 Compressors

1. The chiller must be off.

2. Carefully remove any insulation that may have been

placed over the two lubrication ports of the tang op-

erator base. This insulation will need to be replaced

after the service is complete.

3. Note the position of the tang operator arm, note the

placement of spacing washers etc., then disconnect

the linkage rod from the tang operator arm. Manually

move the tang operator arm and note the amount of

effort required to operate the assembly.

4. Loosen but DO NOT REMOVE the 1/16” NPT lubrica-

tion port plug that is highest on the assembly.

5. Loosen and remove the remaining lower 1/16” NPT

plug.

6. Using a grease gun with an appropriate fitting, insert

ONLY Rheolube grease into the open port until clean

grease is seen to appear around the threads of the

plug in the opposite port.

7. Tighten the plug that was loosened in

Step 4

. Tighten

the plug to hand tight plus 1/4 to 1/2 turn.

8. Remove the grease fitting, if used.

DO NOT LEAVE GREASE FITTINGS INSTALLED.

If grease fittings have been used for this procedure

then they MUST BE REMOVED before returning the

unit to service. Grease fittings are not vacuum-tight

and will become a leak path.

9. Using a clean wooden dowel or other similar tool,

remove excess grease from the remaining open lu-

brication port.

10. Clean and then lightly coat the threads of the plug

with Rheolube grease and re-install it into the lubri-

cation port. Tighten the plug to hand tight plus 1/4 to

1/2 turn.

11. Before reconnecting the vane linkage, grasp the tang

operator arm and manually operate the vane assem-

bly. If it is now difficult to move, then the tang oper-

ator may have become hydraulically locked because

of excess grease in the assembly. This situation could

cause damage to the O-rings of the assembly. If this

occurs then remove one of the lubrication plugs,

remove some of the grease, then re-install the plug.

12. Reconnect the linkage to the tang operator arm.

Ensure the spacer washers between the linkage and

the arm are properly placed and that the assembly

does not bind. Re-install any insulation that was cut

or removed. The unit may be restarted.

Service for the 1st and 2nd Stage Tang

Operators

Extended Capacity Chillers with 1470 or 1720 Com-

pressors.

The 1st and 2nd stage rotary inlet guide vane tang oper-

ators of the extended capacity chillers also require peri-

odic lubrication, at least annually, with Trane approved

R-123 and R514A compatible grease. These actuators

have two 1/8” NPT plugs located 180 degrees apart, with

one on the top and the other on the bottom of the oper-

ator base. Use the same procedure as described above,

except that it will be necessary to temporarily disconnect

the vane actuators from the tang operator arms in order

to test for a hydraulically locked condition.

RELEASED 10/Mar/2020 06:59:20 GMT