1. INTRODUCTION AND DESCRIPTION OF EQUIP-

MENT

The TIRFOR

®

machine is a hand-operated lifting and

pulling machine. It is versatile, portable and multi-pur-

pose, not only for pulling and lifting but also for lowering,

tensioning and guying.

The originality of the TIRFOR

®

machine is the principle

of operation directly on the wire rope which passes

through the mechanism rather than being reeled onto a

drum of a hoist or conventional winch. The pull is

applied by means of two pairs of self-energised jaws

which exert a grip on the wire rope in proportion to the

load being lifted or pulled. A telescopic operating lever

fitted to either the forward or the reverse lever transmits

the effort to the jaw mechanism to give forward or rever-

se movement of the wire rope.

The machine is fitted with a hook or anchor pin, depen-

ding on the model, so that it can be secured quickly to

any suitable anchor point.

TIRFOR

®

machines, intended for lifting and pulling

materials, are available in two ranges each with three

models of different capacities :

– T-500D range for light duty applications (with safety

release catch),

– TU range for heavy duty applications (with safety

release catch).

Each machine is supplied with a telescopic operating

handle, and usually with a 20 m standard length of spe-

cial TIRFOR

®

wire rope fitted with a safety hook and

wound onto a metal reeler. Longer or shorter lengths of

wire rope are available on request.

This manual together with a guarantee card are sup-

plied with each machine, as well as the CE declaration

of conformity.

IMPORTANT : TIRFOR

®

wire rope has been

specially designed to meet the particular require-

ments of the TIRFOR

®

machine.

The manufacturer does not guarantee the safe ope-

ration of machines used with wire rope other than

TIRFOR

®

wire rope.

2. RIGGING ARRANGEMENTS

Various ways of rigging are shown in Figs. 2.1, 2.2, 2.3

and 2.4. Figs. 4 and 5 show particular arrangements

(one forbidden and the other recommended).

The machine may be anchored to a fixed point with the

wire rope travelling towards the machine (Figs. 2.1, 2.2,

2.3), or travel along the wire rope, with the load, the wire

rope itself anchored to a fixed point

(Fig. 2.4).

In example 2.2, the maximum working load of the pulley

and the anchor point should be equal to or greater than

twice the load.

N.B. Whatever the rigging arrangement, and if the

machine is anchored directly to a fixed point, ensure

4

GB

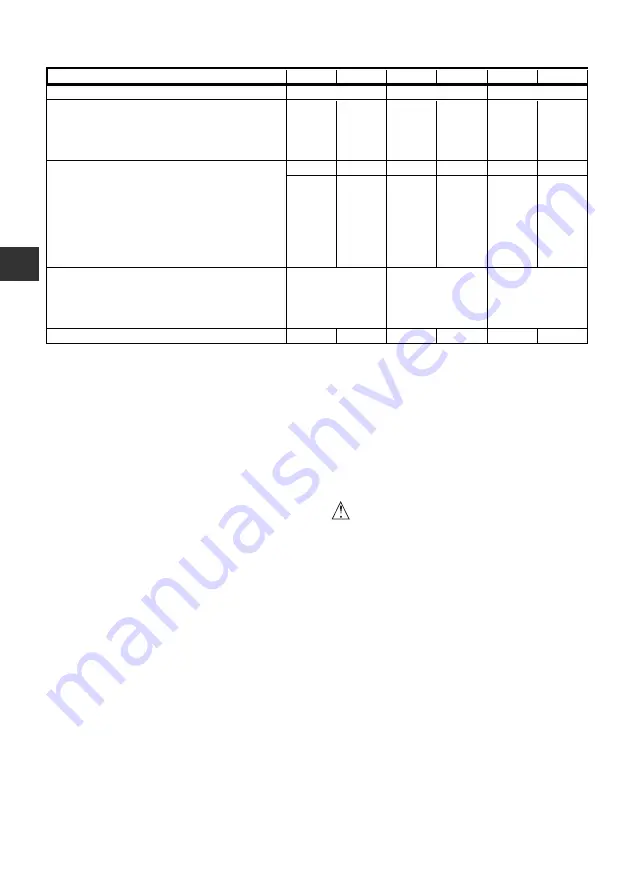

TECHNICAL DATA

* Including end fittings of the wire rope.

** One complete cycle of the operating lever at maximum working load.

MODEL

TU-8

T-508D

TU-16

T-516D

TU-32

T-532D

Maximum working load

t

Weight :

4

2

7

2

5

,

3

1

8

1

6

,

6

4

,

8

g

k

e

n

i

h

c

a

m

telescopic operating handle

kg

1

1

2,4

2,3

2,4

2,3

standard 20 m of wire rope, complete

kg

6,1

6,1

13,1

13,1

26,6

26,6

Total weight of standard equipment

kg

15,5

13,7

33,5

28,9

56

52,9

Machine dimensions :

0

2

6

6

7

6

0

3

5

0

6

6

0

2

4

7

2

5

m

m

h

t

g

n

e

l

length with optional hook

mm

–

550

–

650

860

840

5

5

3

0

3

3

5

1

3

0

3

3

0

5

2

5

6

2

m

m

t

h

g

i

e

h

0

3

1

6

5

1

7

2

1

0

4

1

9

9

8

0

1

m

m

h

t

d

i

w

telescopic handle : closed/extended

cm

51/77

40/69

68/119

65/115

68/119

65/115

TIRFOR wire rope

diameter

mm

guaranteed breaking strain*

daN

weight per meter

kg

Rope travel (forward/reverse)**

mm

70/76

46/63

56/70

42/57

30/48

18/36

4000

8000

16000

0,25

0,5

1

0,8

1,6

3,2

8,3

11,5

16,3