EM09D--01

P14798

P14800

A02035

EM0365

Front

Thrust

Direction

Axial

10 mm

(0.39 in.)

Middle

1

2

2

1

Direction

10 mm

(0.39 in.)

A

C

B

P14783

EM--70

--

ENGINE MECHANICAL

CYLINDER BLOCK (2RZ--FE, 3RZ--F)

INSPECTION

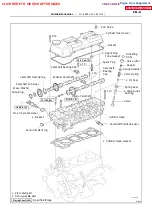

1. REMOVE GASKET MATERIAL

Using a gasket scraper, remove all the gasket material from the

top surface of the cylinder block.

2 . CLE AN CY L I NDE R BLO CK

Using a soft brush and solvent, thoroughly clean the cylinder

block.

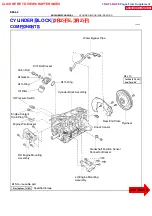

3. INSPECT TOP SURFACE OF CYLINDER BLOCK FOR

FLATNE S S

Using a precision straight edge and thickness gauge, measure

the surfaces contacting the cylinder head gasket for warpage.

Maximum warpage:

0.05 mm (0.0020 in.)

If warpage is greater than maximum, replace the cylinder block.

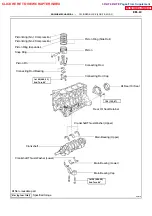

4. INSPECT CYLINDER FOR VERTICAL SCRATCHES

Visually check the cylinder for vertical scratches.

If deep scratches are present, rebore all the 4 cylinders. If nec-

essary, replace the cylinder block.

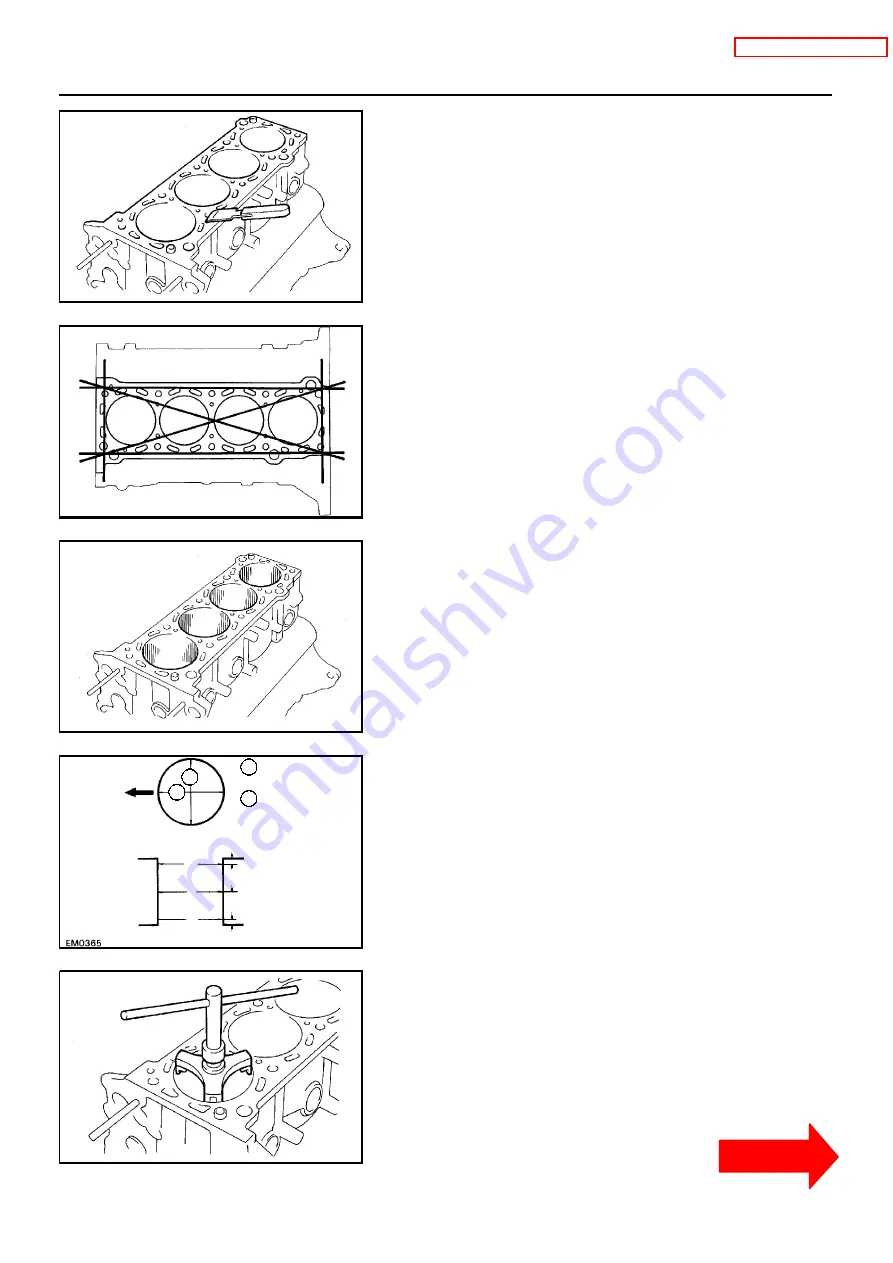

5. INSPECT CYLINDER BORE DIAMETER

Using a cylinder gauge, measure the cylinder bore diameter at

positions A, B and C in the thrust and axial directions.

Standard diameter:

94.990 -- 95.003 mm (3.7400 -- 3.7403 in.)

Maximum diameter:

95.06 mm (3.7425 in.)

If the diameter is greater than maximum, rebore all the 4 cylin-

ders. If necessary, replace the cylinder block.

6 . RE MO V E CY LI NDE R RI DG E

If the wear is less than 0.2 mm (0.008 in.), using a ridge reamer,

grind the top of the cylinder.

CLICK HERE TO VIEW CHAPTER INDEX

Pages From Supplement

3RZ-F,3RZ-FE