P14772

P23480

P14776

P14777

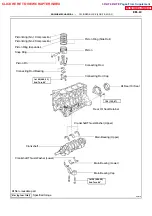

Plastigage

--

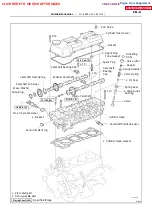

ENGINE MECHANICAL

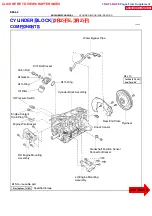

CYLINDER BLOCK (2RZ--FE, 3RZ--F)

EM--65

1 6 . CHE CK CO NNE CTI NG RO D THRUS T CLE ARANCE

Using a dial indicator, measure the thrust clearance while mov-

ing the connecting rod back and forth.

Standard thrust clearance:

0.160 -- 0.312 mm (0.0063 -- 0.0123 in.)

Maximum thrust clearance:

0.35 mm (0.0138 in.)

If the thrust clearance is greater than maximum, replace the

connecting rod assembly. If necessary, replace the crankshaft.

1 7 . RE MO V E CO NNE CTI NG RO D CAP S AND CHE CK

O I L CLE ARANCE

(a)

Check the matchmarks on the connecting rod and cap are

aligned to ensure correct reassembly.

(b)

Remove the connecting rod cap nuts.

(c)

Using a plastic--faced hammer, lightly tap the connecting

rod bolts and lift off the connecting rod cap.

HINT:

Keep the lower bearing inserted with the connecting rod cap.

(d)

Cover the connecting rod bolts with a short piece of hose

to protect the crankshaft from damage.

(e)

Clean the crank pin and bearing.

(f)

Check the crank pin and bearing for pitting and scratches.

If the crank pin or bearing is damaged, replace the bearings. If

necessary, grind or replace the crankshaft.

(g)

Lay a strip of Plastigage across the crank pin.

(h)

Install the connecting rod cap with the 2 nuts.

Torque:

1st 45 N

∙

m (460 kgf

∙

cm, 33 ft

∙

lbf)

2nd Turn 90

˚

NOTICE:

Do not turn the crankshaft.

(i)

Remove the 2 nuts and connecting rod cap.

(See procedure (b) and (c) above)

CLICK HERE TO VIEW CHAPTER INDEX

Pages From Supplement

3RZ-F,3RZ-FE