A01991

A01992

A02359

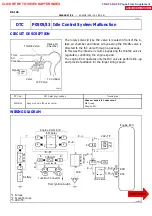

G2+, NE signal waveforms

5V/

Division

5V/

Division

G2+

NE

G2+

NE

20 m sec./Division (Idling)

10 m sec./Division (Idling)

DI--138

--

DIAGNOSTICS

ENGINE (2RZ--FE, 3RZ--FE)

INSPECTION PROCEDURE

HINT:

S

Read freed frame data using hand--held tester. Because freeze frame records the engine conditions

when the malfunction is detected, when troubleshooting it is useful for determining whether the vehicle

was running or stopped, the engine warmed up or not, the air--fuel ratio lean or rich, etc. at the time

of the malfunction.

S

Perfrom troubleshooting of DTC P0335/12 first. If no trouble is found, troubleshoot the following me-

chanical system.

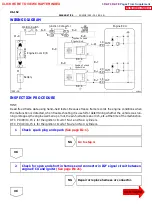

1 Check resistance of crankshaft position sensor

Reference: INSPECTION USING OSCILLOSCOPE

During cranking or idling, check between terminals G2+ and

NE--, NE+ and NE-- of engine ECU

HINT:

The correct waveforms are as shown.

NG

Replace crankshaft position sensor.

OK

2 Check for open and short in harness and connector between engine ECU and

crankshaft position sensor

NG

Repair or replace harness or connector.

OK

CLICK HERE TO VIEW CHAPTER INDEX

Pages From Supplement

3RZ-F,3RZ-FE