P24397

KNK

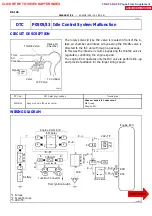

E5 Connector

FI6510

FI6511

A00068

KNK signal waveform

0.5V/

Division

0.5V/

Division

0V

0V

5 m sec./Division

200 sec./Division

--

DIAGNOSTICS

ENGINE (2RZ--FE, 3RZ--FE)

DI--135

INSPECTION PROCEDURE

HINT:

Read freed frame data using hand--held tester. Because freeze frame records the engine conditions when

the malfunction is detected, when troubleshooting it is useful for determining whether the vehicle was run-

ning or stopped, the engine warmed up or not, the air--fuel ratio lean or rich, etc. at the time of the malfunction.

1 Check continuity between terminal KNK of engine ECU connector and body

ground.

PREPARATION:

(a) Remove the glove compartment

).

(b)

Disconnect the E5 connector of engine ECU.

CHECK:

Measure resistance between terminal KNK of engine ECU con-

nector and body ground.

OK:

Resistance: 1 M

Ω

or higher

Reference: INSPECTION USING OSCILLOSCOPE

S

With the engine racing (4,000 rpm) measure between ter-

minal KNK of engine ECU and body ground.

HINT:

The correct waveform is as shown.

S

Spread the time on the horizontal axis, and confirm that

period of the wave is 151

µ

sec.

(Normal mode vibration frequency of knock sensor:

6.6 kHz).

HINT:

If normal mode vibration frequency is not 6.6 kHz the sensor is

malfunctioning.

NG

CLICK HERE TO VIEW CHAPTER INDEX

Pages From Supplement

3RZ-F,3RZ-FE