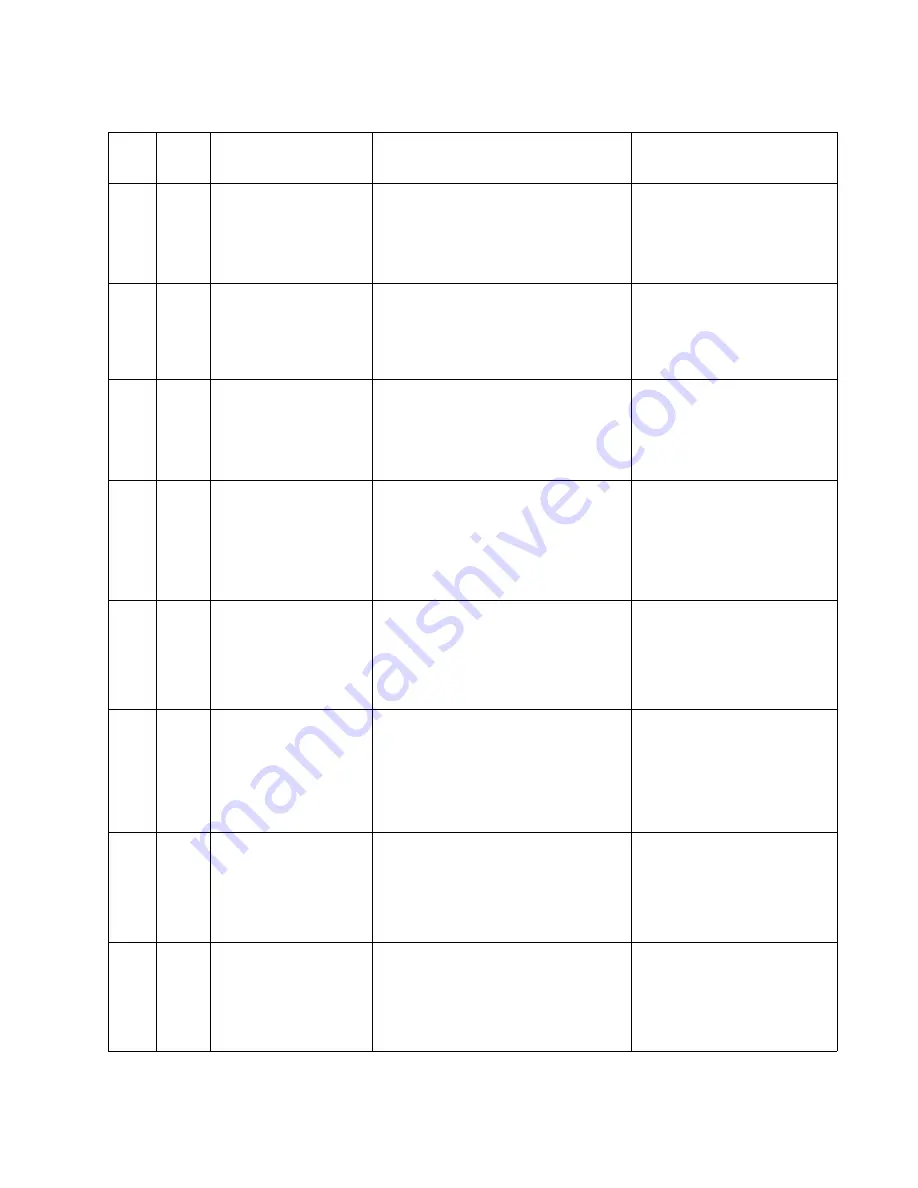

Diagnostic information

2-19

922

.44

Hot roll timed out in

trying to reach the final

lamp detection

temperature. Fuser

page count between

400,000 and 499,999.

• Low wattage or incorrect lamp.

• Bad thermistor, circuit, or cabling.

• Fuser not receiving sufficient AC

power.

• Poor supply line voltage.

Go to

“922.xx—Cold fuser

check” on page 2-89

.

922

.45

After hot roll lamp

detection, did not roll

over to steady state

control in time. Fuser

page count between

400,000 and 499,999.

The control code has been lost.

Go to

“922.xx—Cold fuser

check” on page 2-89

.

922

.46

Hot roll did not reach

operating temperature in

time (new enhanced

control). Fuser page

count between 400,000

and 499,999.

• Low wattage or incorrect lamp.

• Bad thermistor, circuit, or cabling.

• Fuser not receiving sufficient AC

power.

• Poor supply line voltage.

Go to

“922.xx—Cold fuser

check” on page 2-89

.

922

.47

Fuser has taken too long

to reach desired

temperature after

increasing interpage

gap. Fuser page count

between 400,000 and

499,999.

• Low wattage or incorrect lamp.

• Bad thermistor, circuit, or cabling.

• Excessive load on the fuser.

• Fuser not receiving sufficient AC

power.

• Poor supply line voltage.

Go to

“922.xx—Cold fuser

check” on page 2-89

.

922

.52

Hot roll took too long to

reach the beginning

lamp detection

temperature. Fuser

page count stopped at

500,000 to preserve

data.

• Low wattage or incorrect lamp.

• Bad thermistor, circuit, or cabling.

• Fuser not receiving sufficient AC

power.

• Poor supply line voltage.

Go to

“922.xx—Cold fuser

check” on page 2-89

.

922

.53

Hot roll reached final

lamp detection

temperature but took

longer than largest time

in lookup table. Fuser

page count stopped at

500,000 to preserve

data.

• Low wattage or incorrect lamp.

• Bad thermistor, circuit, or cabling.

• Fuser not receiving sufficient AC

power.

• Poor supply line voltage.

Go to

“922.xx—Cold fuser

check” on page 2-89

.

922

.54

Hot roll timed out in

trying to reach the final

lamp detection

temperature. Fuser

page count stopped at

500,000 to preserve

data.

• Low wattage or incorrect lamp.

• Bad thermistor, circuit, or cabling.

• Fuser not receiving sufficient AC

power.

• Poor supply line voltage.

Go to

“922.xx—Cold fuser

check” on page 2-89

.

922

.55

After hot roll lamp

detection, did not roll

over to steady state

control in time. Fuser

page count stopped at

500,000 to preserve

data.

The control code has been lost.

Go to

“922.xx—Cold fuser

check” on page 2-89

.

Service error codes (9

xx

.

xx

) (continued)

Error

code

Sub

codes

Display text

Description

Action

Содержание e-STUDIO500P

Страница 1: ...PRINTER P N 12G9609 e STUDIO500P ...

Страница 10: ...x Service Manual ...

Страница 15: ...Laser notices xv Japanese Laser Notice ...

Страница 16: ...xvi Service Manual Korean Laser Notice ...

Страница 22: ...1 2 S ervice Manual Configured model The following illustration shows a standard network printer ...

Страница 43: ...Diagnostic information 2 7 ...

Страница 159: ...Diagnostic information 2 123 ...

Страница 160: ...2 124 Service Manual ...

Страница 161: ...Diagnostic information 2 125 ...

Страница 181: ...Diagnostic aids 3 17 ...

Страница 205: ...Pages 3 42 through 3 44 have been removed from this document intentionally Diagnostic aids 3 41 ...

Страница 286: ...Connector locations and connections 5 1 5 Connector locations and connections Connections System board ...

Страница 297: ...5 12 Service Manual ...

Страница 298: ...Connector locations and connections 5 13 ...

Страница 299: ...5 14 Service Manual ...

Страница 301: ...6 2 Service Manual ...

Страница 303: ...7 2 Service Manual Assembly 1 Covers ...

Страница 305: ...7 4 Service Manual Assembly 2 Frame 1 ...

Страница 307: ...7 6 Service Manual Assembly 3 Frame 2 ...

Страница 309: ...7 8 Service Manual Assembly 4 Frame 3 ...

Страница 311: ...7 10 Service Manual Assembly 5 Printhead ...

Страница 313: ...7 12 Service Manual Assembly 6 Paper feed autocompensator ...

Страница 315: ...7 14 Service Manual 4061 xx0 Assembly 7 Paper feed multipurpose feeder ...

Страница 317: ...7 16 Service Manual Assembly 8 Paper feed alignment ...

Страница 319: ...Page 7 19 has been removed from this document intentionally 7 18 Service Manual ...

Страница 320: ...7 20 Service Manual Assembly 10 Integrated 500 sheet paper tray ...

Страница 322: ...7 22 Service Manual Assembly 11 Drives Main drive and developer drive ...

Страница 324: ...7 24 Service Manual Assembly 12 Hot roll fuser ...

Страница 326: ...7 26 Service Manual Assembly 13 Transfer charging ...

Страница 328: ...7 28 Service Manual Assembly 14 Electronics power supplies ...

Страница 330: ...7 30 Service Manual Note ...

Страница 332: ...7 32 Service Manual Assembly 16 Electronics shields ...

Страница 336: ...7 36 Service Manual Assembly 19 Cabling diagrams 3 ...

Страница 338: ...7 38 Service Manual Assembly 20 Cabling diagrams 4 ...

Страница 340: ...7 40 Service Manual Assembly 21 Cabling diagrams 5 ...

Страница 342: ...7 42 S ervice Manual THE FOLLOWING PAGE 7 43 HAS BEEN OMITTED FROM THIS MANUAL INTENTIONALLY ...

Страница 347: ...7 48 S ervice Manual Pages 7 49 through 7 57 of this manual have been omitted intentionally ...

Страница 348: ...7 58 Service Manual Assembly 35 High capacity feeder 1 ...

Страница 350: ...7 60 Service Manual Assembly 36 High capacity feeder 2 ...

Страница 354: ...7 64 S ervice Manual Pages 7 65 thru 7 70 ofthis manual were omitted intentionally ...

Страница 362: ...I 8 Service Manual ...

Страница 370: ...I 16 Service Manual ...