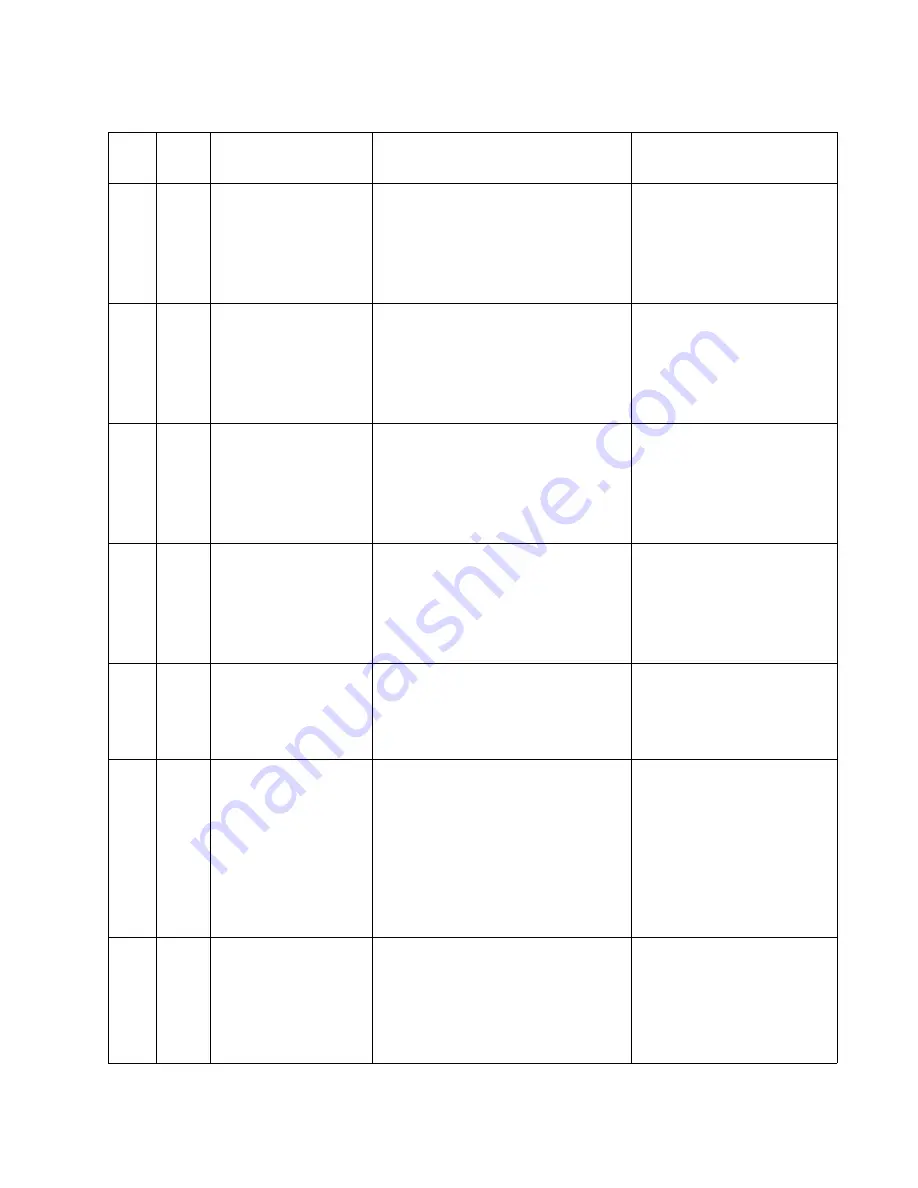

Diagnostic information

2-9

920

.01

Hot roll took too long to

heat up after

transitioning to new

enhanced mode

(standby control only.

Fuser page count

between 0 and 99,999.

• Bad thermistor, circuit or cabling.

• Fuser not receiving sufficient AC

power.

• Poor supply line voltage.

• Low wattage or incorrect lamp.

• Incorrect hot roll.

Go to

“920.xx—Cold fuser

service check” on page 2-87

.

920

.02

Hot roll fell too far below

the desired temperature

while in standby. Fuser

page between 0 and

99,999.

• Bad thermistor, circuit or cabling.

• Fuser not receiving sufficient AC

power.

• Poor supply line voltage.

• Low wattage or incorrect lamp.

• Incorrect hot roll.

Go to

“920.xx—Cold fuser

service check” on page 2-87

.

920

.03

Hot roll too cool when

checking for slope

change in standby.

Fuser page count

between 0 and 99,999.

• Bad thermistor, circuit or cabling.

• Fuser not receiving sufficient AC

power.

• Poor supply line voltage.

• Low wattage or incorrect lamp.

• Incorrect hot roll.

Go to

“920.xx—Cold fuser

service check” on page 2-87

.

920

.04

Hot roll too cool when

heating to desired

temperature after slope

change (standby control

only). Fuser page count

between 0 and 99,999.

• Bad thermistor, circuit or cabling.

• Fuser not receiving sufficient AC

power.

• Poor supply line voltage.

• Low wattage or incorrect lamp.

• Incorrect hot roll.

Go to

“920.xx—Cold fuser

service check” on page 2-87

.

920

.06

Fuser is not increasing

in temperature even

though the lamp has

been on for an extended

time. Fuser page count

between 0 and 99,999.

• Fuser is not receiving AC power.

• Poor supply line voltage.

Go to

“920.xx—Cold fuser

service check” on page 2-87

.

920.

.07

Fuser has been below

the desired temperature

for too long while media

is in the nip. Fuser page

count between 0 and

99,999.

• Bad thermistor, circuit, or cabling.

• Very noisy thermistor signal.

• Fuser not receiving AC power.

• Poor supply line voltage.

• Excessive load on the fuser.

• Low voltage or incorrect lamp.

• Abrupt change in temperature that

has disrupted control.

• Incorrect hot roll.

Go to

“920.xx—Cold fuser

service check” on page 2-87

.

920

.11

Hot roll took too long to

heat up after

transitioning to new

enhanced mode. Fuser

page count between

100,000 and 199,999.

• Bad thermistor, circuit, or cabling.

• Very noisy thermistor signal.

• Fuser not receiving AC power.

• Poor supply line voltage.

• Low voltage or incorrect lamp.

• Incorrect hot roll.

Go to

“920.xx—Cold fuser

service check” on page 2-87

.

Service error codes (9

xx

.

xx

) (continued)

Error

code

Sub

codes

Display text

Description

Action

Содержание e-STUDIO500P

Страница 1: ...PRINTER P N 12G9609 e STUDIO500P ...

Страница 10: ...x Service Manual ...

Страница 15: ...Laser notices xv Japanese Laser Notice ...

Страница 16: ...xvi Service Manual Korean Laser Notice ...

Страница 22: ...1 2 S ervice Manual Configured model The following illustration shows a standard network printer ...

Страница 43: ...Diagnostic information 2 7 ...

Страница 159: ...Diagnostic information 2 123 ...

Страница 160: ...2 124 Service Manual ...

Страница 161: ...Diagnostic information 2 125 ...

Страница 181: ...Diagnostic aids 3 17 ...

Страница 205: ...Pages 3 42 through 3 44 have been removed from this document intentionally Diagnostic aids 3 41 ...

Страница 286: ...Connector locations and connections 5 1 5 Connector locations and connections Connections System board ...

Страница 297: ...5 12 Service Manual ...

Страница 298: ...Connector locations and connections 5 13 ...

Страница 299: ...5 14 Service Manual ...

Страница 301: ...6 2 Service Manual ...

Страница 303: ...7 2 Service Manual Assembly 1 Covers ...

Страница 305: ...7 4 Service Manual Assembly 2 Frame 1 ...

Страница 307: ...7 6 Service Manual Assembly 3 Frame 2 ...

Страница 309: ...7 8 Service Manual Assembly 4 Frame 3 ...

Страница 311: ...7 10 Service Manual Assembly 5 Printhead ...

Страница 313: ...7 12 Service Manual Assembly 6 Paper feed autocompensator ...

Страница 315: ...7 14 Service Manual 4061 xx0 Assembly 7 Paper feed multipurpose feeder ...

Страница 317: ...7 16 Service Manual Assembly 8 Paper feed alignment ...

Страница 319: ...Page 7 19 has been removed from this document intentionally 7 18 Service Manual ...

Страница 320: ...7 20 Service Manual Assembly 10 Integrated 500 sheet paper tray ...

Страница 322: ...7 22 Service Manual Assembly 11 Drives Main drive and developer drive ...

Страница 324: ...7 24 Service Manual Assembly 12 Hot roll fuser ...

Страница 326: ...7 26 Service Manual Assembly 13 Transfer charging ...

Страница 328: ...7 28 Service Manual Assembly 14 Electronics power supplies ...

Страница 330: ...7 30 Service Manual Note ...

Страница 332: ...7 32 Service Manual Assembly 16 Electronics shields ...

Страница 336: ...7 36 Service Manual Assembly 19 Cabling diagrams 3 ...

Страница 338: ...7 38 Service Manual Assembly 20 Cabling diagrams 4 ...

Страница 340: ...7 40 Service Manual Assembly 21 Cabling diagrams 5 ...

Страница 342: ...7 42 S ervice Manual THE FOLLOWING PAGE 7 43 HAS BEEN OMITTED FROM THIS MANUAL INTENTIONALLY ...

Страница 347: ...7 48 S ervice Manual Pages 7 49 through 7 57 of this manual have been omitted intentionally ...

Страница 348: ...7 58 Service Manual Assembly 35 High capacity feeder 1 ...

Страница 350: ...7 60 Service Manual Assembly 36 High capacity feeder 2 ...

Страница 354: ...7 64 S ervice Manual Pages 7 65 thru 7 70 ofthis manual were omitted intentionally ...

Страница 362: ...I 8 Service Manual ...

Страница 370: ...I 16 Service Manual ...