2-110

Service Manual

Output expander service check

Service tip: The majority of the mechanical components can be observed during operation by removing the left,

right, and system board covers. The output expander functions without the covers installed.

Make sure the option is correctly installed before attempting to service the unit. No jumpers should be installed

at connector J6 on the output expander board.

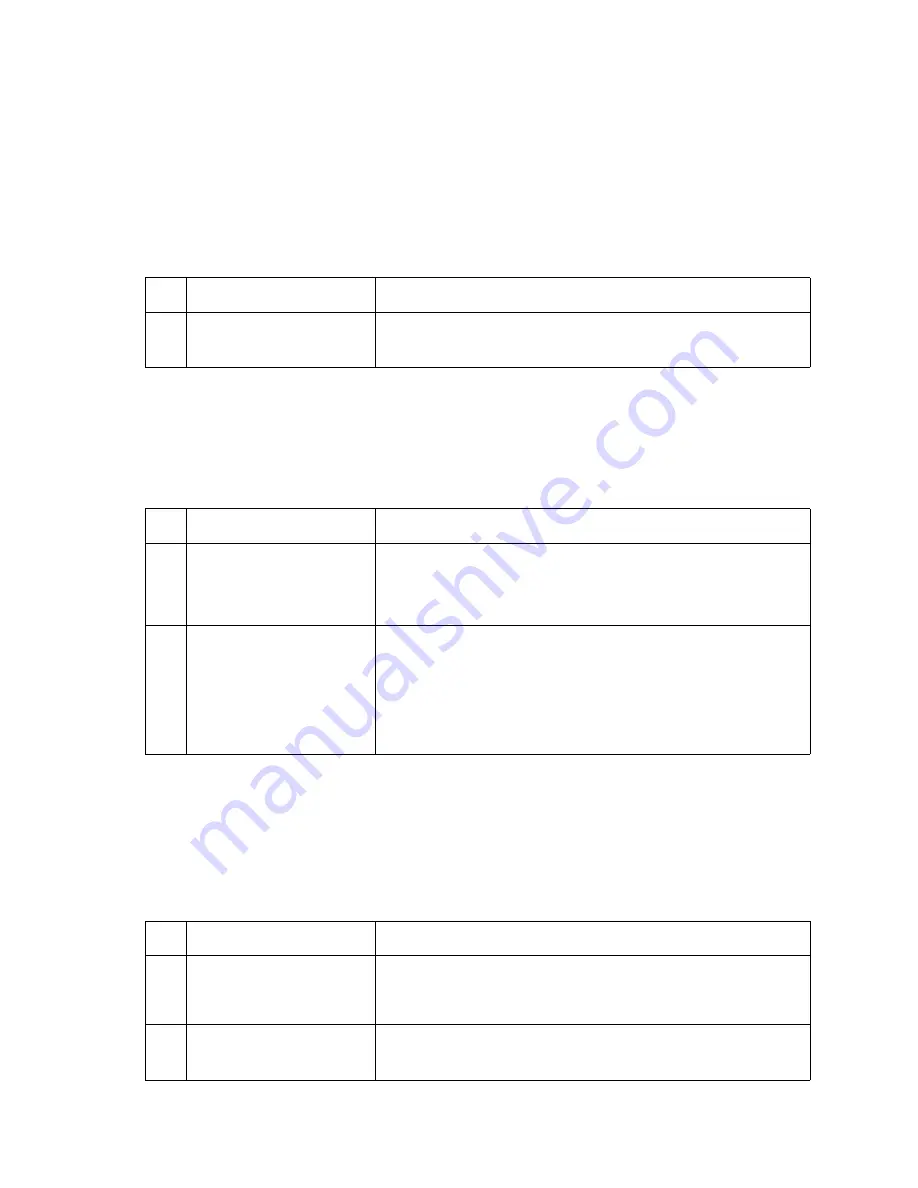

Problems with excessive static electricity buildup

Printer does not recognize one or more output expander options as being installed

Service tip: If more than a single output expander option is installed, check each one to see if the printer

recognizes any single option as being installed. If the printer recognizes any of the output expander options then

the base printer autoconnect system is operating correctly and the problem is in the unrecognized expander

option.

202.xx Paper Jam Open Rear Door

message displays; a sheet of paper is

jammed prior to the pass thru sensor flag

202.xx

Paper Jam Open Rear Door

message displays; a sheet of paper feeds out to

the standard bin even though bin

x

is selected; paper exits half way out of the redrive

Service tip: For this type of problem check the sub error codes. They can help isolate the problem. 202 Paper

Jam messages can also occur prior to the output expander pass thru sensor.

FRU

Action

1

Output expander control

board cover

Check the output expander control board cover to make sure the

ESD brush ground lead is firmly attached to the output expander

frame. Also make sure the ESD brush is not loose.

FRU

Action

1

Output expander option

Make sure the output expander option is the only option that is not

recognized by the base printer. If the output expander is the only

option not recognized by the printer, continue with step 2. If not,

check the autoconnects of the options not recognized and the

interconnect card and cable connections.

2

Output expander assembly

mechanical linkage

Check the autoconnects for damage, especially the connector pins.

Remove the left and right side covers. Remove the front control board

cover. Check the cables at J1A, J1B, J2A and J2B on the control

board to make sure they are attached securely and correctly.

Remove the output expander and check the voltages on the output

bin autoconnect located on the top left rear of the printer. Go to

“Autoconnect” on page 5-6

. If the voltages are correct and the

problem persists, replace the output expander option.

FRU

Action

1

Output expander drive belt

Pulley drive belt

Idler pulley belt tension

spring

Check to ensure the output expander drive belt is correctly installed

on the drive pulley and belt idler pulley. Check the belt tension spring

to make sure it is not loose or broken. Repair as necessary.

2

Mechanical linkage

DC motor assembly

If the DC motor is functioning properly check the gears, clutch, and

other linkage parts for correct operation and wear, broken gear teeth,

or damaged parts. If incorrect, replace the output expander option.

Содержание e-STUDIO500P

Страница 1: ...PRINTER P N 12G9609 e STUDIO500P ...

Страница 10: ...x Service Manual ...

Страница 15: ...Laser notices xv Japanese Laser Notice ...

Страница 16: ...xvi Service Manual Korean Laser Notice ...

Страница 22: ...1 2 S ervice Manual Configured model The following illustration shows a standard network printer ...

Страница 43: ...Diagnostic information 2 7 ...

Страница 159: ...Diagnostic information 2 123 ...

Страница 160: ...2 124 Service Manual ...

Страница 161: ...Diagnostic information 2 125 ...

Страница 181: ...Diagnostic aids 3 17 ...

Страница 205: ...Pages 3 42 through 3 44 have been removed from this document intentionally Diagnostic aids 3 41 ...

Страница 286: ...Connector locations and connections 5 1 5 Connector locations and connections Connections System board ...

Страница 297: ...5 12 Service Manual ...

Страница 298: ...Connector locations and connections 5 13 ...

Страница 299: ...5 14 Service Manual ...

Страница 301: ...6 2 Service Manual ...

Страница 303: ...7 2 Service Manual Assembly 1 Covers ...

Страница 305: ...7 4 Service Manual Assembly 2 Frame 1 ...

Страница 307: ...7 6 Service Manual Assembly 3 Frame 2 ...

Страница 309: ...7 8 Service Manual Assembly 4 Frame 3 ...

Страница 311: ...7 10 Service Manual Assembly 5 Printhead ...

Страница 313: ...7 12 Service Manual Assembly 6 Paper feed autocompensator ...

Страница 315: ...7 14 Service Manual 4061 xx0 Assembly 7 Paper feed multipurpose feeder ...

Страница 317: ...7 16 Service Manual Assembly 8 Paper feed alignment ...

Страница 319: ...Page 7 19 has been removed from this document intentionally 7 18 Service Manual ...

Страница 320: ...7 20 Service Manual Assembly 10 Integrated 500 sheet paper tray ...

Страница 322: ...7 22 Service Manual Assembly 11 Drives Main drive and developer drive ...

Страница 324: ...7 24 Service Manual Assembly 12 Hot roll fuser ...

Страница 326: ...7 26 Service Manual Assembly 13 Transfer charging ...

Страница 328: ...7 28 Service Manual Assembly 14 Electronics power supplies ...

Страница 330: ...7 30 Service Manual Note ...

Страница 332: ...7 32 Service Manual Assembly 16 Electronics shields ...

Страница 336: ...7 36 Service Manual Assembly 19 Cabling diagrams 3 ...

Страница 338: ...7 38 Service Manual Assembly 20 Cabling diagrams 4 ...

Страница 340: ...7 40 Service Manual Assembly 21 Cabling diagrams 5 ...

Страница 342: ...7 42 S ervice Manual THE FOLLOWING PAGE 7 43 HAS BEEN OMITTED FROM THIS MANUAL INTENTIONALLY ...

Страница 347: ...7 48 S ervice Manual Pages 7 49 through 7 57 of this manual have been omitted intentionally ...

Страница 348: ...7 58 Service Manual Assembly 35 High capacity feeder 1 ...

Страница 350: ...7 60 Service Manual Assembly 36 High capacity feeder 2 ...

Страница 354: ...7 64 S ervice Manual Pages 7 65 thru 7 70 ofthis manual were omitted intentionally ...

Страница 362: ...I 8 Service Manual ...

Страница 370: ...I 16 Service Manual ...