Diagnostic information

2-97

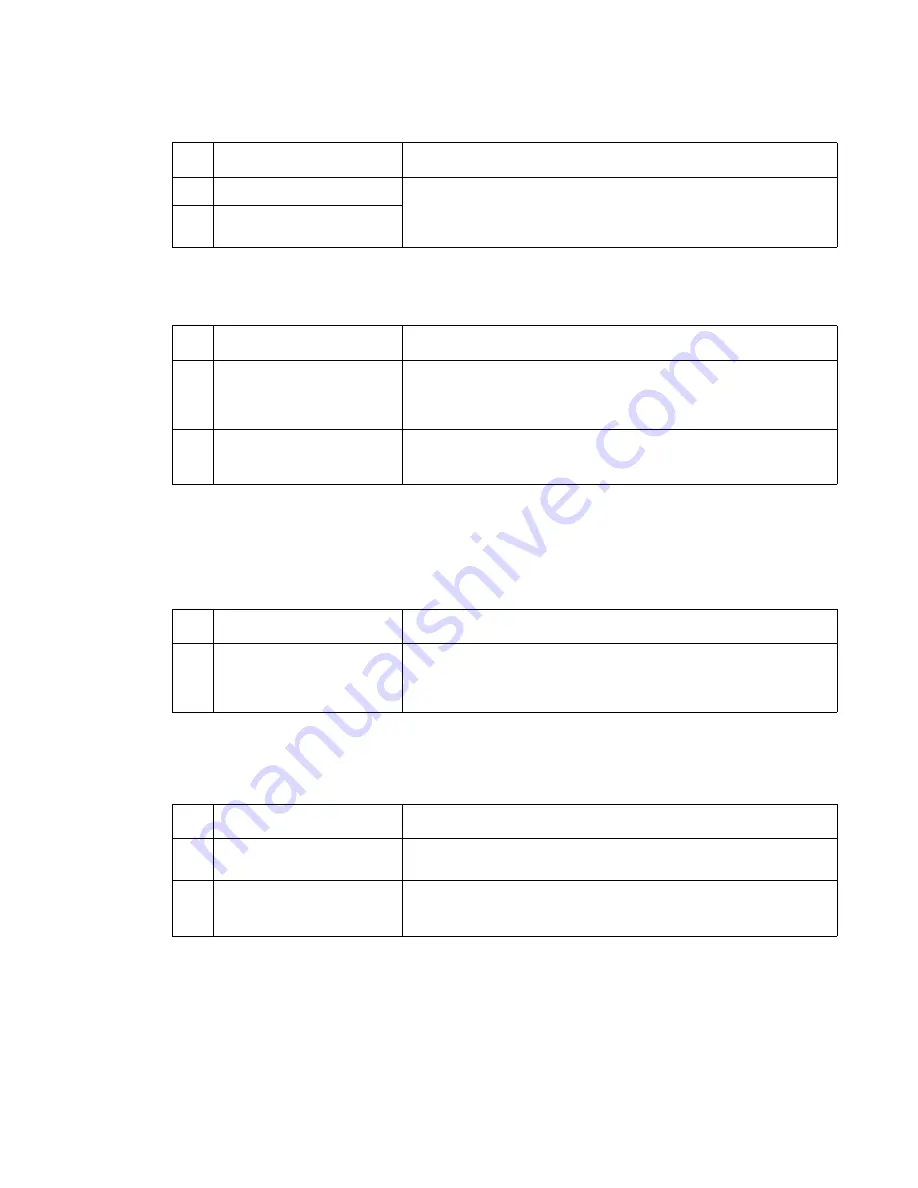

Tray

x

Empty

displays when there is paper in the high-capacity feeder input tray

The elevator tray fails to stop at the correct position and continues to drive into the

bottom frame

The elevator tray down button does not operate. The tray moves to the upper position

Service tip: Open the high-capacity feeder front door and check the black rubber bumper attached to the door

switch spring. Be sure the rubber button is centered and not touching the sides of the hole or the switch will not

function properly.

Paper from the high-capacity feeder input tray does not reach the pass thru sensor

Service tip: Be sure the paper in tray is within specifications.

FRU

Action

1

Paper out sensor flag

Check the paper out sensor flag for correct operation and installation.

If correct, replace the high-capacity feeder system board. (The paper

out sensor is mounted on the high-capacity feeder system board.)

2

Paper out sensor

(on option system board)

FRU

Action

1

Lower limit switch

Lower limit switch cable

Check continuity of the lower limit switch. If incorrect, replace the

switch. If correct, check the switch cable. If incorrect, replace the

cable. If correct, replace the high-capacity feeder option control

board.

2

High-capacity feeder

control board

Disconnect the lower limit switch cable and check the voltage at J2-1

(orange). The voltage measures approxi5 V dc. If incorrect,

replace the high-capacity feeder option control board.

FRU

Action

1

Lower limit switch

Lower limit switch cable

High-capacity feeder

control board

Check the lower limit switch to make sure it is not closed (normally

open). If incorrect, replace the switch. Check the lower limit switch

cable for a short between pins 1 and 2. If incorrect, replace the cable.

If correct, replace the high-capacity feeder control board.

FRU

Action

1

Autocompensator

assembly

Check the autocompensator pick arm rollers for sign of glazing, toner

or other buildup. Replace as necessary.

2

Wear strips

Check the wear strips for glazing or contamination. Replace as

required. It is advisable to replace all four wear strips at the same

time.

Содержание e-STUDIO500P

Страница 1: ...PRINTER P N 12G9609 e STUDIO500P ...

Страница 10: ...x Service Manual ...

Страница 15: ...Laser notices xv Japanese Laser Notice ...

Страница 16: ...xvi Service Manual Korean Laser Notice ...

Страница 22: ...1 2 S ervice Manual Configured model The following illustration shows a standard network printer ...

Страница 43: ...Diagnostic information 2 7 ...

Страница 159: ...Diagnostic information 2 123 ...

Страница 160: ...2 124 Service Manual ...

Страница 161: ...Diagnostic information 2 125 ...

Страница 181: ...Diagnostic aids 3 17 ...

Страница 205: ...Pages 3 42 through 3 44 have been removed from this document intentionally Diagnostic aids 3 41 ...

Страница 286: ...Connector locations and connections 5 1 5 Connector locations and connections Connections System board ...

Страница 297: ...5 12 Service Manual ...

Страница 298: ...Connector locations and connections 5 13 ...

Страница 299: ...5 14 Service Manual ...

Страница 301: ...6 2 Service Manual ...

Страница 303: ...7 2 Service Manual Assembly 1 Covers ...

Страница 305: ...7 4 Service Manual Assembly 2 Frame 1 ...

Страница 307: ...7 6 Service Manual Assembly 3 Frame 2 ...

Страница 309: ...7 8 Service Manual Assembly 4 Frame 3 ...

Страница 311: ...7 10 Service Manual Assembly 5 Printhead ...

Страница 313: ...7 12 Service Manual Assembly 6 Paper feed autocompensator ...

Страница 315: ...7 14 Service Manual 4061 xx0 Assembly 7 Paper feed multipurpose feeder ...

Страница 317: ...7 16 Service Manual Assembly 8 Paper feed alignment ...

Страница 319: ...Page 7 19 has been removed from this document intentionally 7 18 Service Manual ...

Страница 320: ...7 20 Service Manual Assembly 10 Integrated 500 sheet paper tray ...

Страница 322: ...7 22 Service Manual Assembly 11 Drives Main drive and developer drive ...

Страница 324: ...7 24 Service Manual Assembly 12 Hot roll fuser ...

Страница 326: ...7 26 Service Manual Assembly 13 Transfer charging ...

Страница 328: ...7 28 Service Manual Assembly 14 Electronics power supplies ...

Страница 330: ...7 30 Service Manual Note ...

Страница 332: ...7 32 Service Manual Assembly 16 Electronics shields ...

Страница 336: ...7 36 Service Manual Assembly 19 Cabling diagrams 3 ...

Страница 338: ...7 38 Service Manual Assembly 20 Cabling diagrams 4 ...

Страница 340: ...7 40 Service Manual Assembly 21 Cabling diagrams 5 ...

Страница 342: ...7 42 S ervice Manual THE FOLLOWING PAGE 7 43 HAS BEEN OMITTED FROM THIS MANUAL INTENTIONALLY ...

Страница 347: ...7 48 S ervice Manual Pages 7 49 through 7 57 of this manual have been omitted intentionally ...

Страница 348: ...7 58 Service Manual Assembly 35 High capacity feeder 1 ...

Страница 350: ...7 60 Service Manual Assembly 36 High capacity feeder 2 ...

Страница 354: ...7 64 S ervice Manual Pages 7 65 thru 7 70 ofthis manual were omitted intentionally ...

Страница 362: ...I 8 Service Manual ...

Страница 370: ...I 16 Service Manual ...