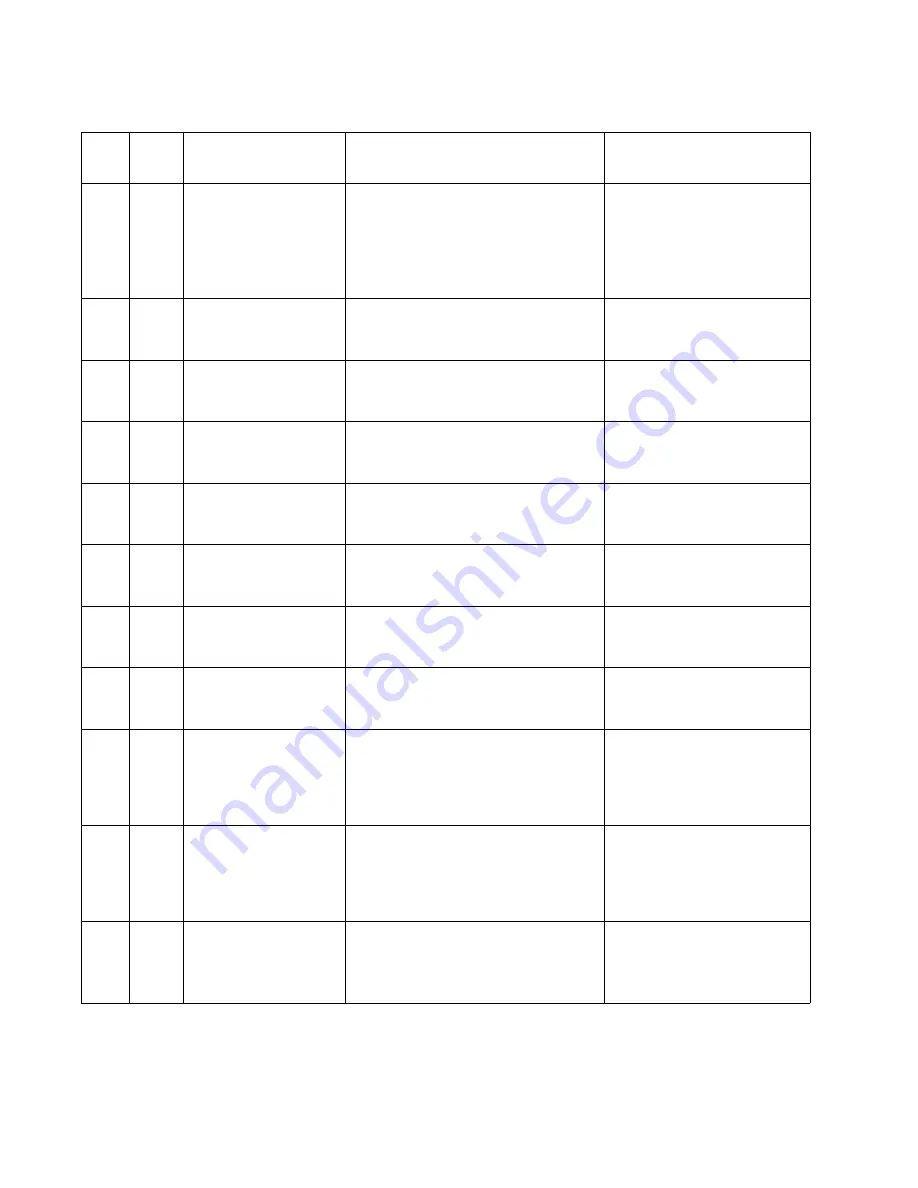

2-70

Service Manual

238

.07

Duplex doublefeed,

input, and exit sensors

are covered.

• Media left in the duplex and

Continue

selected.

• Sensor is having mechanical or

electrical problems.

• Remove any sheets from

the duplex option.

• Try the duplex option again.

If it fails, try another duplex

option, if available. If one is

not available, replace the

duplex option.

239

.00

Feed error in duplex

unit.

• Mechanical feed error due to belt

slipping.

• Timing error due to feed system.

Replace the duplex option.

239

.01

Jam declared by a smart

device. Immediate stop.

• Mechanical feed error due to belt

slipping.

• Timing error due to feed system.

Replace the duplex option.

239

.02

Jam declared by a smart

device. Homing allowed

stop.

• Mechanical feed error due to belt

slipping.

• Timing error due to feed system.

Replace the duplex option.

239

.03

Duplex did not send

device Controls

response.

• Mechanical feed error due to belt

slipping.

• Timing error due to feed system.

Replace the duplex option.

239

.04

Duplex did not send

Input Device Ready

response.

• Mechanical feed error due to belt

slipping.

• Timing error due to feed system.

Replace the duplex option.

239

.05

Duplex did not send

Page In Output Device

response.

• Mechanical feed error due to belt

slipping.

• Timing error due to feed system.

Replace the duplex option.

239

.06

Failed the last page of a

staple job.

• Mechanical feed error due to belt

slipping.

• Timing error due to feed system.

Replace the duplex option.

239

.07

Engine never sent

Select OUtput Device to

the duplex unit because

the page leaving the

duplex never sent Select

Input Device.

• Mechanical feed error due to belt

slipping.

• Timing error due to feed system.

Replace the duplex option.

239

.08

Engine never saw Input

Source Read on a page

to be picked from the

duplex unit that is

waiting on a page to

pass the input sensor.

• Mechanical feed error due to belt

slipping.

• Timing error due to feed system.

Replace the duplex option.

239

.11

Sheet picked from

duplex never made it to

the input sensor. Slow or

delayed feed from the

duplex unit.

• Mechanical feed error due to belt

slipping.

• Timing error due to feed system.

• Input sensor not working correctly.

Check duplex sensor cables for

correct installation. If no

problem is found with the

cables, replace the duplex

option.

User attendance messages—paper jams and paper handling errors (2

xx.xx

)

Error

code

Sub

codes

Description

Possible causes

Action

Содержание e-STUDIO500P

Страница 1: ...PRINTER P N 12G9609 e STUDIO500P ...

Страница 10: ...x Service Manual ...

Страница 15: ...Laser notices xv Japanese Laser Notice ...

Страница 16: ...xvi Service Manual Korean Laser Notice ...

Страница 22: ...1 2 S ervice Manual Configured model The following illustration shows a standard network printer ...

Страница 43: ...Diagnostic information 2 7 ...

Страница 159: ...Diagnostic information 2 123 ...

Страница 160: ...2 124 Service Manual ...

Страница 161: ...Diagnostic information 2 125 ...

Страница 181: ...Diagnostic aids 3 17 ...

Страница 205: ...Pages 3 42 through 3 44 have been removed from this document intentionally Diagnostic aids 3 41 ...

Страница 286: ...Connector locations and connections 5 1 5 Connector locations and connections Connections System board ...

Страница 297: ...5 12 Service Manual ...

Страница 298: ...Connector locations and connections 5 13 ...

Страница 299: ...5 14 Service Manual ...

Страница 301: ...6 2 Service Manual ...

Страница 303: ...7 2 Service Manual Assembly 1 Covers ...

Страница 305: ...7 4 Service Manual Assembly 2 Frame 1 ...

Страница 307: ...7 6 Service Manual Assembly 3 Frame 2 ...

Страница 309: ...7 8 Service Manual Assembly 4 Frame 3 ...

Страница 311: ...7 10 Service Manual Assembly 5 Printhead ...

Страница 313: ...7 12 Service Manual Assembly 6 Paper feed autocompensator ...

Страница 315: ...7 14 Service Manual 4061 xx0 Assembly 7 Paper feed multipurpose feeder ...

Страница 317: ...7 16 Service Manual Assembly 8 Paper feed alignment ...

Страница 319: ...Page 7 19 has been removed from this document intentionally 7 18 Service Manual ...

Страница 320: ...7 20 Service Manual Assembly 10 Integrated 500 sheet paper tray ...

Страница 322: ...7 22 Service Manual Assembly 11 Drives Main drive and developer drive ...

Страница 324: ...7 24 Service Manual Assembly 12 Hot roll fuser ...

Страница 326: ...7 26 Service Manual Assembly 13 Transfer charging ...

Страница 328: ...7 28 Service Manual Assembly 14 Electronics power supplies ...

Страница 330: ...7 30 Service Manual Note ...

Страница 332: ...7 32 Service Manual Assembly 16 Electronics shields ...

Страница 336: ...7 36 Service Manual Assembly 19 Cabling diagrams 3 ...

Страница 338: ...7 38 Service Manual Assembly 20 Cabling diagrams 4 ...

Страница 340: ...7 40 Service Manual Assembly 21 Cabling diagrams 5 ...

Страница 342: ...7 42 S ervice Manual THE FOLLOWING PAGE 7 43 HAS BEEN OMITTED FROM THIS MANUAL INTENTIONALLY ...

Страница 347: ...7 48 S ervice Manual Pages 7 49 through 7 57 of this manual have been omitted intentionally ...

Страница 348: ...7 58 Service Manual Assembly 35 High capacity feeder 1 ...

Страница 350: ...7 60 Service Manual Assembly 36 High capacity feeder 2 ...

Страница 354: ...7 64 S ervice Manual Pages 7 65 thru 7 70 ofthis manual were omitted intentionally ...

Страница 362: ...I 8 Service Manual ...

Страница 370: ...I 16 Service Manual ...