W W W . T M G I N D U S T R I A L . C O M

P 2 0 / 4 1

T o l l F r e e : 1 - 8 7 7 - 7 6 1 - 2 8 1 9

MAINTENANCE INSTRUCTIONS

Read and follow all the maintenance instructions provided

in this manual to keep the machine in good operating

condition. Regular inspections and proper maintenance

are essential to preventing accidents and injuries. These

instructions will help you service the unit. Instructions are

for a person with some mechanical ability and training. No

attempt has been made to describe all basic steps like how

to loosen or tighten fasteners. Basic procedures such as

cycling systems and checking operation of the equipment

are not fully described since they are described in this

manual. Do not attempt to perform work beyond your ability

or at which you have no experience. If you need assistance,

call an authorized service center or contact the factory.

The motor on this machine contains high voltage. Disconnect

power at the receptacle before performing any electrical

repairs. Secure plug so that it cannot be accidentally plugged

in during service.

DAILY

On a daily basis, inspect the unit and check to be

certain that all systems are operating normally. Follow

detailed inspection and testing procedures as specified for

various components at regular intervals.

Replace any damaged or missing safety decal’s. They

are available from the factory.

Make sure all fasteners are securely tightened and all

safety locks, controls, knobs, hooks, pins and guards and

covers are in place and operating correctly.

Check for worn, damaged or missing parts. Replace

them before allowing the unit to be used.

MONTHLY

Check operation of the mount/demount tool holder.

The sliding table / carriage, clamps, bead breaking

head, and other working surfaces should be cleaned with a

vaporizing solvent every month.

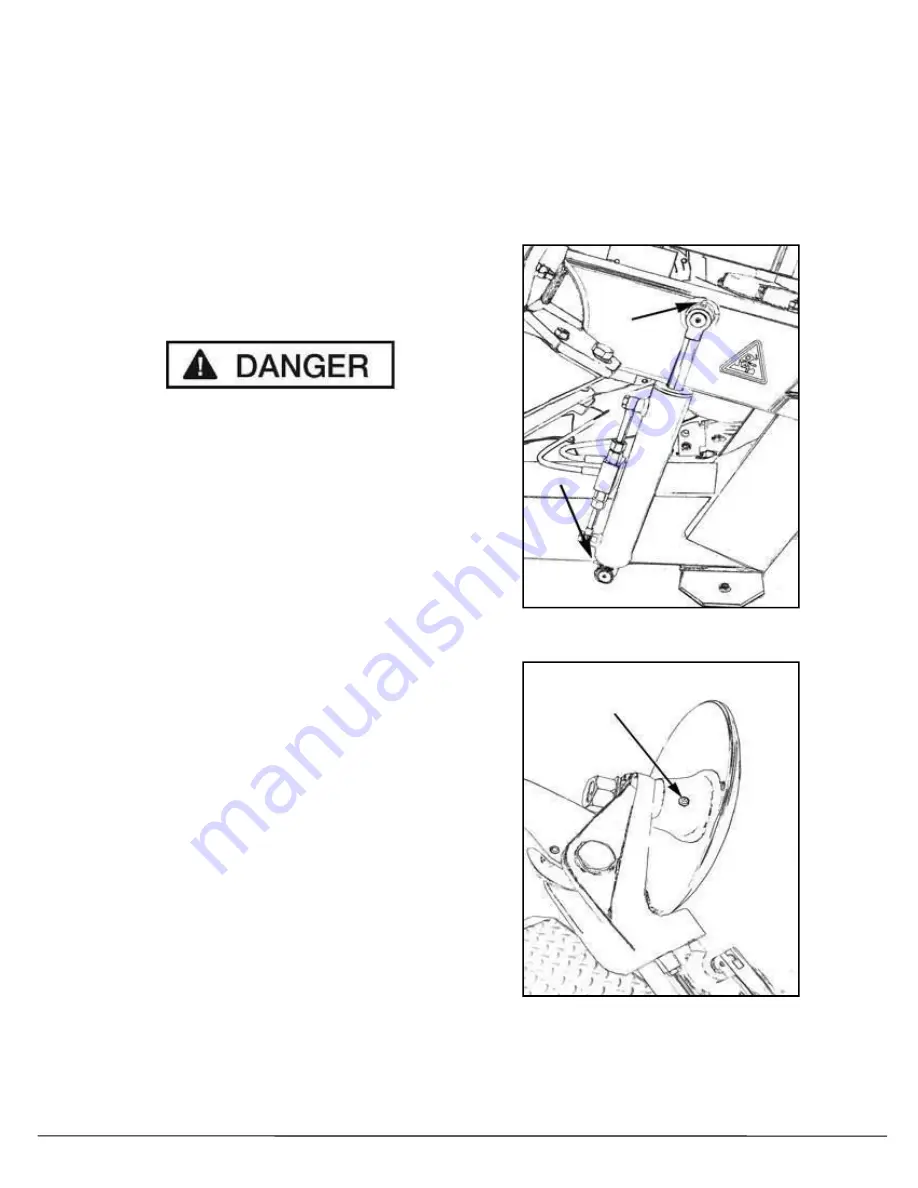

EVERY SIX WEEKS

Grease periodically the following parts, after having cleaned

them carefully with diesel oil:

Carriage slides.

Horizontal tool holding arm spindle.

Grease the horizontal arm lifting cylinder.

Grease the Bead Breaking Disc Shaft.