TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

TM

N

CO

V EYORS

7/21

9

•

Too tight of a belt will usually pulsate as it moves through the frame. Another indication that

a belt is too tight is when there is an above normal ampere draw. Excessive tension causes

increased wear and reduced belt life.

•

Too loose of a belt buckles as it leaves the infeed sprockets and as it contacts the drive sprockets.

This condition often causes jamming and can easily damage the belt.

MOTORS

1. CLEANING

- All motors should be kept free of dirt and grease accumulations. Open motors should be periodically

vacuumed to remove dust and dirt fromthe windings.

2. VENTILATION

- For best results motors should be operated in an area where adequate ventilation is available.

3. TEMPERATURE

- Most of todays smooth body T.E.N.V. and T.E.F.C. motors run hot to the touch. As long as

maximum ambient temperatures are not exceeded, and more importantly, ampere draw is within the allowable

range, there should be no need to worry. (Both of these limits are found on the motor nameplate.)

4. LUBRICATION

- Most electric motors are lubricated for life and under normal conditions require no more lubrication.

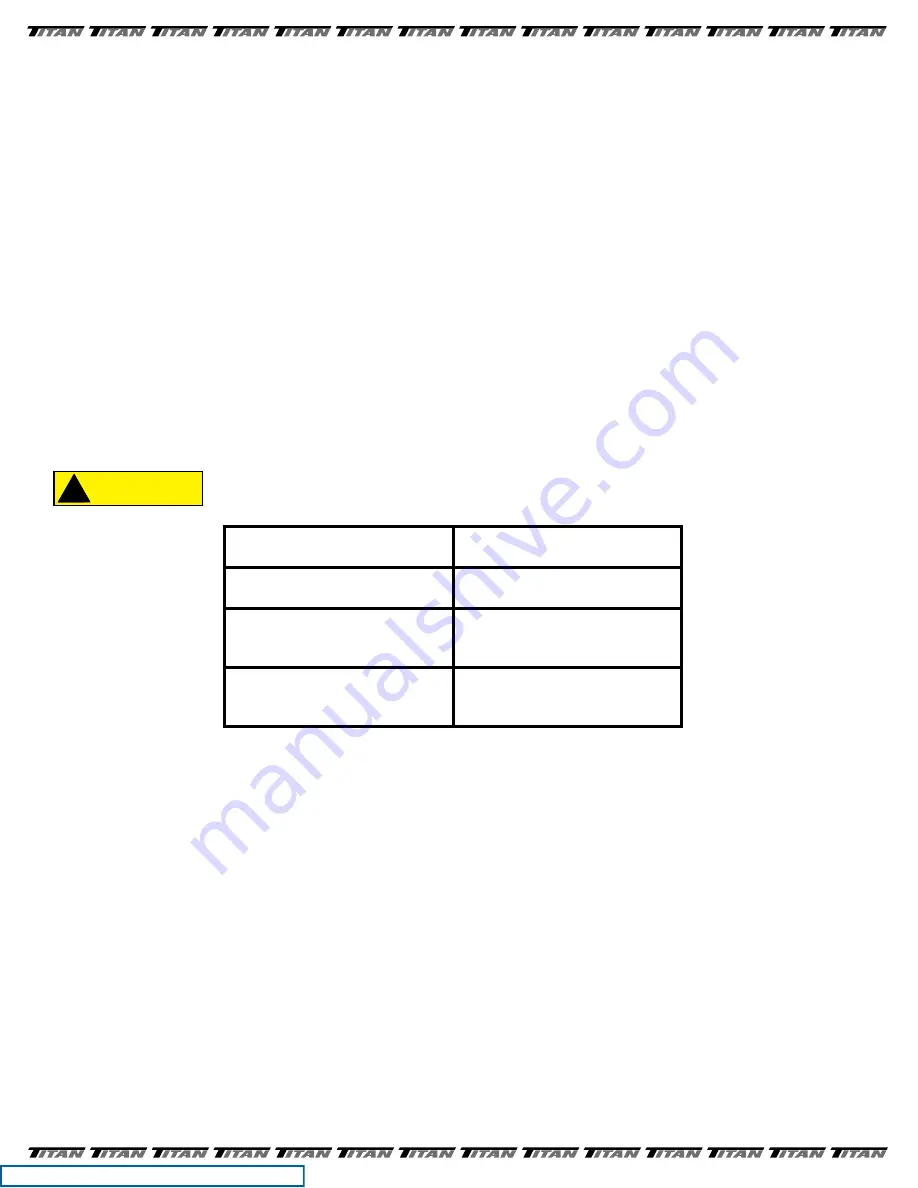

Under severe conditions where additional lubrication is required, use the following chart as a guide.

The following chart is based on motors with grease lubricated bearings, running at

speeds of 1750 R.P.M. or less, and operating within an ambient temperature range of

between 0 degrees F.

to 120 degrees F.

Typical lubricants that can be used:

Chevron Oil Co. - SRI #2

Gulf Refining Co. - Precision #2 or #3

Shell Oil Co. - Alvania #2, Dolium R

Mobile Oil Co. - Mobilux Grease #2

Texaco Inc. - Premium RB

Sinclair Refining Co. - A.F. #2

REDUCERS

The following reducer information is concerned primarily with worm gear reducers. If your conveyor is equipped with another

type, refer to the manufacturer’s recommendations for installation and maintenance sent along at time of shipment.

1.

ASSEMBLE / DISASSEMBLE MOTOR TO REDUCER

- Because many of today's motor keyways are cut with

a sidemill cutter, the following assembly instructions should be followed to insure a trouble-free fit between motor

and reducer. First, place the key into the reducer keyway. Second, line up the motor keyseat with the key and

push the motor shaft into the reducer bore. Third, finish assembly by bolting themotor to the reducer flange.

This insures that the key does not slide back in the motor keyseat. See

FIGURE 5

.

CAUTION

!

CONDITION

LUBRICATING

FREQUENCY

Normal 8 hr. day

Light Loads

2 to 3 years

Heavy 24 hr. Day

Heavy Loads

Dirty Conditions

1 Year

Extreme

Shock Loads

High Temperatures

3 to 6 Months

Go to Table of Contents