Installation, use and maintenance guide

COMPACT S22

–S26–S32 EVO5

Page

48

ENG

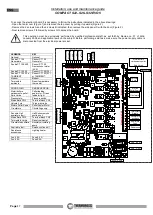

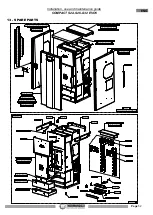

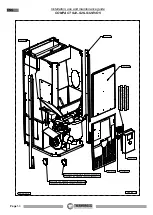

12 – INFORMATION FOR THE SKILLED TECHNICIAN

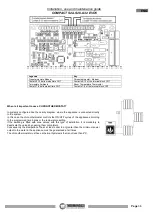

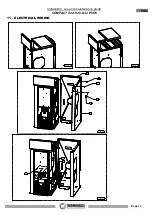

12.1 MAIN COMPONENTS AND THEIR POSITION

SMOKE PRESSURE SWITCH

This is a safety switch that stops the screw feeder motor whenever necessary. The main cause for the pressure switch tripping is a

blocked flue outlet or smoke exhaust pipe. Note that it is strictly forbidden to apply any kind of mesh screen to the end of the pipe.

When the holes of the mesh clog up they create a plug that trips the pressure switch which stops the pellet feeder.

SCREW FEEDER MOTOR

This motor is powered at regular on/off intervals controlled by a microprocessor. The operation of this motor is affected when: The

motor's thermal cutout trips; the pressure switch trips due to blocked smoke exhaust; the generator is shut down intentionally or the

heater shuts down because it runs out of pellets; the manual reset thermostat trips.

SMOKE SUCTION UNIT

This is activated when the start up signal is given. Initially it activates at the maximum capacity, and then self adjusts to the optimal

speed. To enable the evacuation of the smoke and for greater safety of the system, the smoke suction unit continues to operat e for

a preset period of time from when the appliance shuts off.

BRAZIER CLEANING MOTOR

This is a patented system that creates a continual movement of the combustion pellets inside the burner which consequently cleans

the burner.

SMOKE SENSOR

Continually detects the outgoing smoke temperature. It authorises the passage from the Start stage to the Work stage.

EXPANSION TANK

This is a safety device for the appliance used to compensate the increased water volume in the appliance due to its increasing

temperature (Attention: this tank is intended solely as protection for the appliance).

SAFETY THERMOSTAT WITH MANUAL RESET

When the temperature exceeds 98°C the pellet feed screw shuts down. After having verified and solved the causes for the

overtemperature, reactivate the appliance by unscrewing the plastic cover of the thermostat and press the button (the temperature

of the appliance must have dropped considerably).

SPARK PLUG

It is activated in the START phase. It heats the incoming air to the brazier up to 800°C, which promotes the first combustion of the

pellets in the brazier.

AUTOMATIC PURGE VALVE

The function of this valve is to eliminate air residues inside the appliance body without the need for manual intervention.

Consequently problems such as the following are eliminated:

• corrosive processes caused by the oxygen • noise generated by the passage of air in the tubes • air pockets in the heating bodies

• cavitation in the circulator pumps.

SAFETY VALVE CALIBRATED AT 3 BAR

When the calibrated pressure is reached, the valve opens and, by discharging to the atmosphere it prevents the pressure in th e

system from reaching dangerous limits for the generator and for the components of the system. If it trips verify the reasons and

solve the causes for the overpressure.

It is recommended to connect this valve to an outlet to avoid damaging the material around the appliance and to prevent damage

caused by hot water under pressure.

SYSTEM CIRCULATING PUMP

This device conveys hot water produced by the appliance to the usage points. The circulating pump signal appears to indicate that

it is operating.

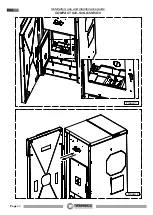

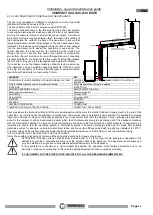

12.2 GUIDELINES FOR CORRECT INSTALLATION

• Read this instruction booklet.

• The appliance must always be switched off from the control panel. It is forbidden to switch off the appliance by means of the main

switch 0/I.

• The appliance must never be disconnected from the electrical power supply and the power supply must never be cut off during

normal operation. Whenever the appliance is deliberately disconnected from the electric power supply smoke could be emitted into

the room.