Refrigeration Service Operations

110

4. Use the appropriate Allen tool to loosen the

coupling mounting screw.

5. Once the center screw has been loosened,

back the head against the tool and it should

push the coupling off the crankshaft as you

continuing turning the center screw in a

counter-clockwise direction. Using this tool

will prevent the coupling from popping off

because the center bolt and flatwasher will

hold it in place.

Compressor Coupling Installation

(Model 30)

In a tapered fit joint the entire twisting load

should be handled by the friction fit between the

two tapered parts. The key is only a backup and is

used to index the parts correctly. When a taper fit

is machined and assembled properly a key is not

needed. In fact, if the key is not installed correctly

it may be worse than no key at all! If the key does

not fit easily into the keyway, it will push the

tapered components apart and the reduced friction

could lead to slippage and premature failure.

The following procedure requires the key to be

fitted after the tapers are pulled together with

20 ft-lb (27 N•m) torque. This insures that the key

cannot hold the tapers apart when the final bolt

torque is applied.

Use the following procedure to install a

compressor coupling on the compressor

crankshaft.

1. Clean the compressor shaft taper and coupling

bore taper with a solvent that leaves no oily

residue (such as naphtha, lacquer thinner,

brake cleaner or the like).

2. Inspect both mating surfaces for burrs,

oxidation and other surface imperfections.

Dress with crocus cloth if necessary and

re-clean as required.

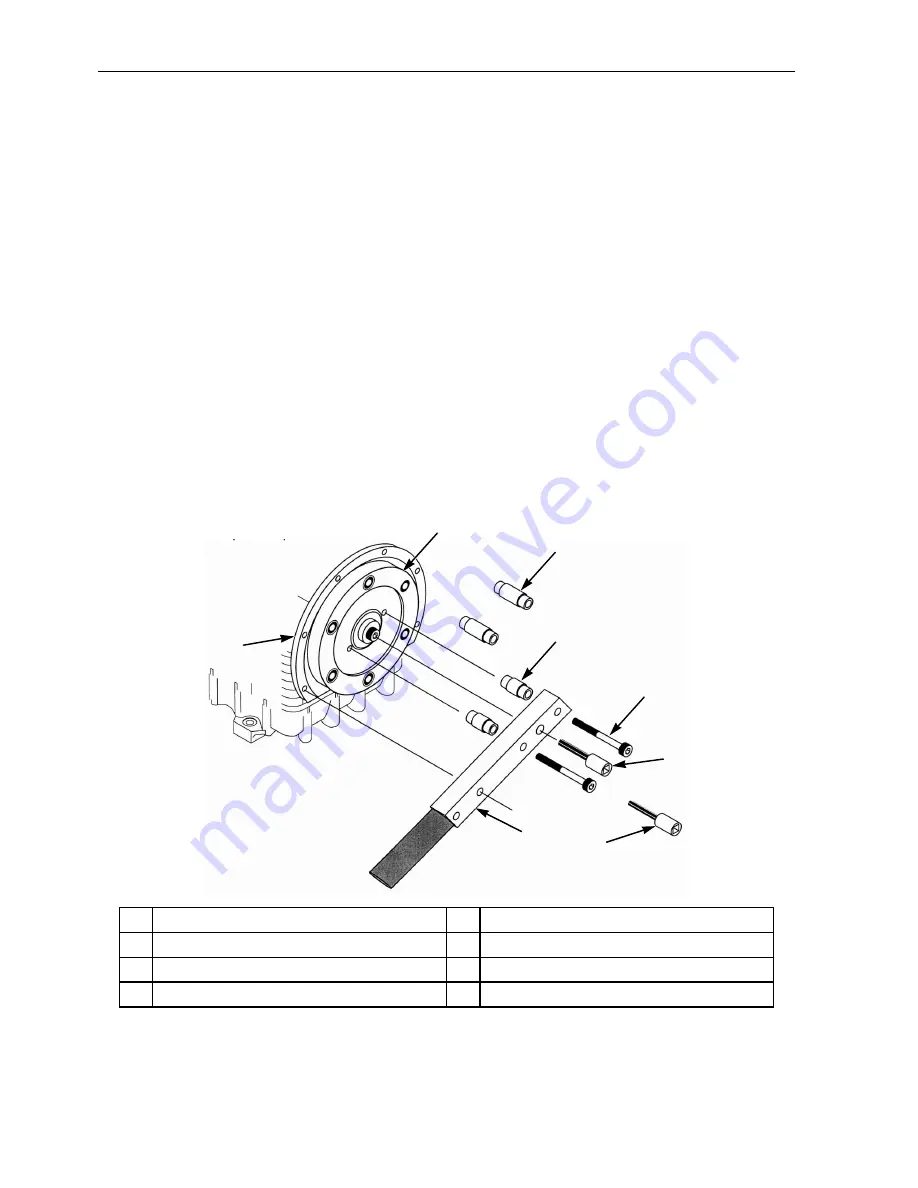

AGA1059

1

3

4

8

5

6

7

2

1.

Coupling

5.

10 mm Allen Tool (for large shaft compressor)

2.

Long Spacers (supplied with tool)

6.

5/16 Allen Tool (for small shaft compressors)

3.

Short Spacers (supplied with tool)

7.

Coupling Removal Tool (P/N 204-991)

4.

Socket Head Bolts (supplied with tool)

8.

Engine Mounting Flange

Figure 95: Compressor Coupling Removal Tool

Содержание SB-210

Страница 4: ...4 ...

Страница 12: ...List of Figures 12 ...

Страница 31: ...Unit Description 31 Unit Photos Figure 6 Front View AJA1617 ...

Страница 32: ...Unit Description 32 1 Defrost Damper 2 X430L Compressor 3 TK 486 Engine Figure 7 Back View 2 3 1 AJA1930 ...

Страница 36: ...Unit Description 36 ...

Страница 49: ...Operating Instructions 49 Figure 32 Viewing Sensors Screen Sequence ...

Страница 54: ...Operating Instructions 54 Figure 40 Datalogger Screen Sequence ...

Страница 101: ...Engine Maintenance 101 ...

Страница 102: ...Engine Maintenance 102 ...

Страница 140: ...Electric Standby Diagnosis 140 ...

Страница 150: ...Index 150 ...

Страница 152: ...Wiring Diagram Index 152 ...

Страница 153: ...153 Model 30 and 50 Schematic Diagram Page 1 of 3 ...

Страница 154: ...154 Model 30 and 50 Schematic Diagram Page 2 of 3 ...

Страница 155: ...155 Model 30 and 50 Schematic Diagram Page 3of 3 ...

Страница 156: ...156 Model 30 and 50 Wiring Diagram Page 1 of 4 ...

Страница 157: ...157 Model 30 and 50 Wiring Diagram Page 2 of 4 ...

Страница 158: ...158 Model 30 and 50 Wiring Diagram Page 3 of 4 ...

Страница 159: ...159 Model 30 and 50 Wiring Diagram Page 4 of 4 ...