Electric boilers MINI BTH

Installation & Operating Manual (Revision: May 2015),

8

The main air eliminator must be installed near

the outlet of the boiler on the highest point of the

main supply piping. It is imperativel to insure that

all air possibly located in the boiler be eliminated

at all time.

3.4.6 Circulating pump

The pump shall be selected such as to be able

to supply adequate flow in relation to the heating

distribution system on which it will be connected

and the heating capacity of the boiler installed.

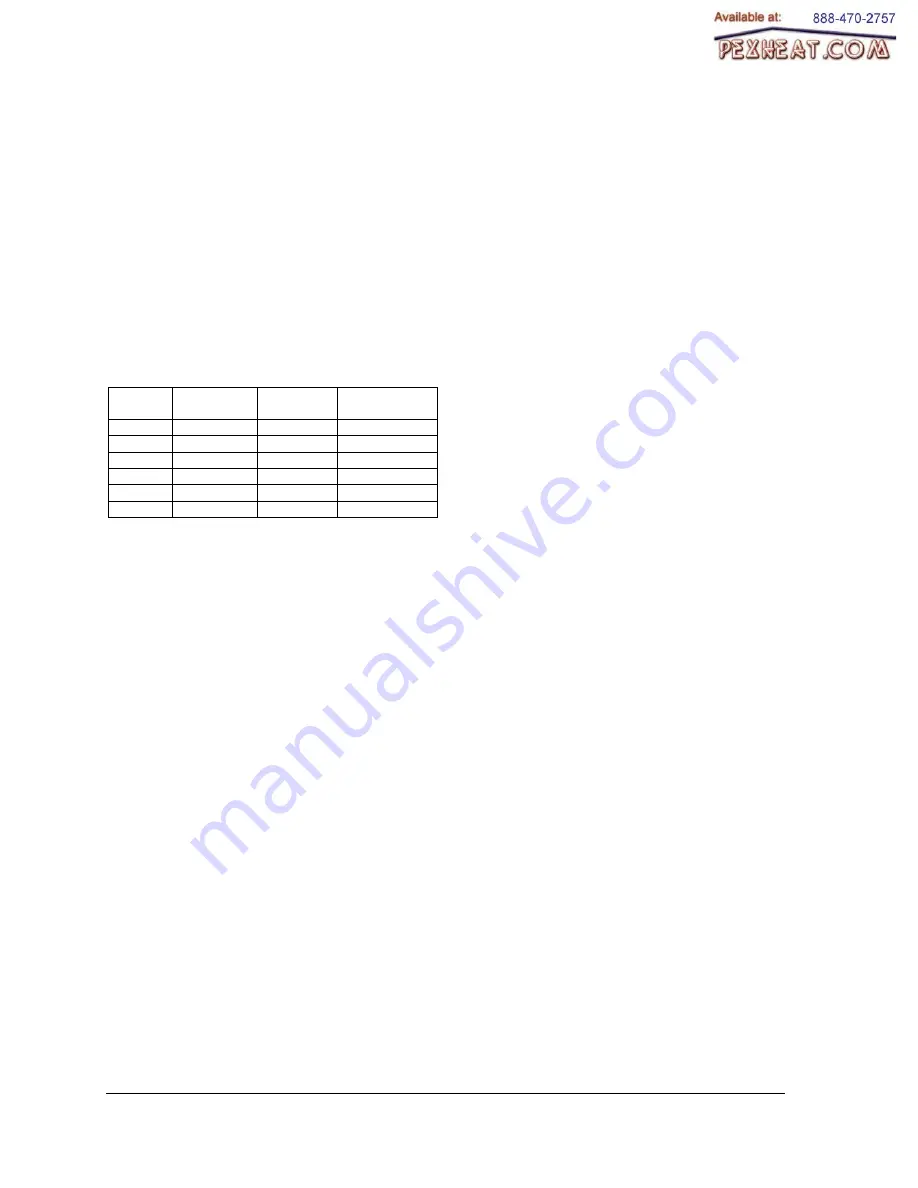

Table below will give you details on required

water flow for distribution systems having to

operate with a temperature differential of 10F

and 20F between their inlet and outlet

.

Model

Diff. 10°F

usgpm

Diff. 20°F

usgpm

Boiler press.

loss

3 kW

2.0

1.0

insignificant

4.5 kW

3.0

1.5

insignificant

6 kW

4.1

2.0

insignificant

7.5 kW

5.1

2.5

insignificant

9 kW

6.1

3.0

insignificant

12 kW

8.2

4.1

insignificant

Your heating wholesaler shall be able to

recommend the appropriate model for your

application.

The amperage drawn by the pump and other

120volts components must not exceed 15 amps.

3.4.7 Drain valve

Installed at the lowest point of the unit, it allows

the unit to be drained for the eventual

replacement of a defective component.

3.4.8 Strainer

This component could be required on old

heating distribution systems made of steel or

cast iron that could carry sediments and sludge.

If such sediments accumulate at the bottom of

the boiler it could be harmful to the heat transfer

of the elements and generate premature

failures.

3.5 ELECTRICAL CONNECTIONS

3.5.1 Main boiler supply

Boiler wiring and grounding must conform to the

National Electrical Code and to state or local

code

requirements.

The

latter

having

precedence.

The electrical supply can be done in two

different ways depending on the necessity of

supplying or not external accessories (such as a

pump) at 120Vac.

If the boiler electrical supply is on 208V, the

position of wire terminal on the transformer

connected to 240V will have to be changed to

208V.

Alternative #1: A 120VAC electrical supply is

required to serve external accessories

.

Electrical wiring must come from a 120/240

Vac/or 120/208Vac -

1ph “L1-N-L2-” circuit

protected by a properly sized breaker.

Alternative #2: No 120Vac electrical supply is

required to serve external accessories (pump

is supplied by a separate circuit)

Electrical wiring must come from a 240Vac or

208Vac- 1ph/

60hz “L1-L2” circuit protected by a

properly sized breaker.

Wire gage must be properly sized by a qualified

electrician in such a way as to meet the national

electrical code.

To do so, consult the boiler rating plate which

will indicate the amperage drawn by the boiler at

full capacity. Extra amperage will have to be

added if external electrical equipments are

connected to the boiler.

This value and the electrical code will be used to

determine the electric cable required together

with the appropriate breaker.

Many other factors must be taken into

consideration in the selection of the appropriate

electrical material such as the length and the

type of cable used, the environment where the

cable will be installed and the type of the over-

current protection used.

The main terminal block of the boiler is suitable

for #14 to #2 wires.

Supply cables can be made of Aluminum or

Copper and be rated for a minimum of 75

o

C

(165

o

F).

If aluminum cables are used, it shall be of an

adequate size (generally bigger) and particular

consideration will have to be respected such as

the use of DE-OX inhibitors in order to meet the

National electrical code.