Quick Start Guide for Equipment Touch and

LS-1628 Unit Controller, Standard 3.1.5 Program

Introduction

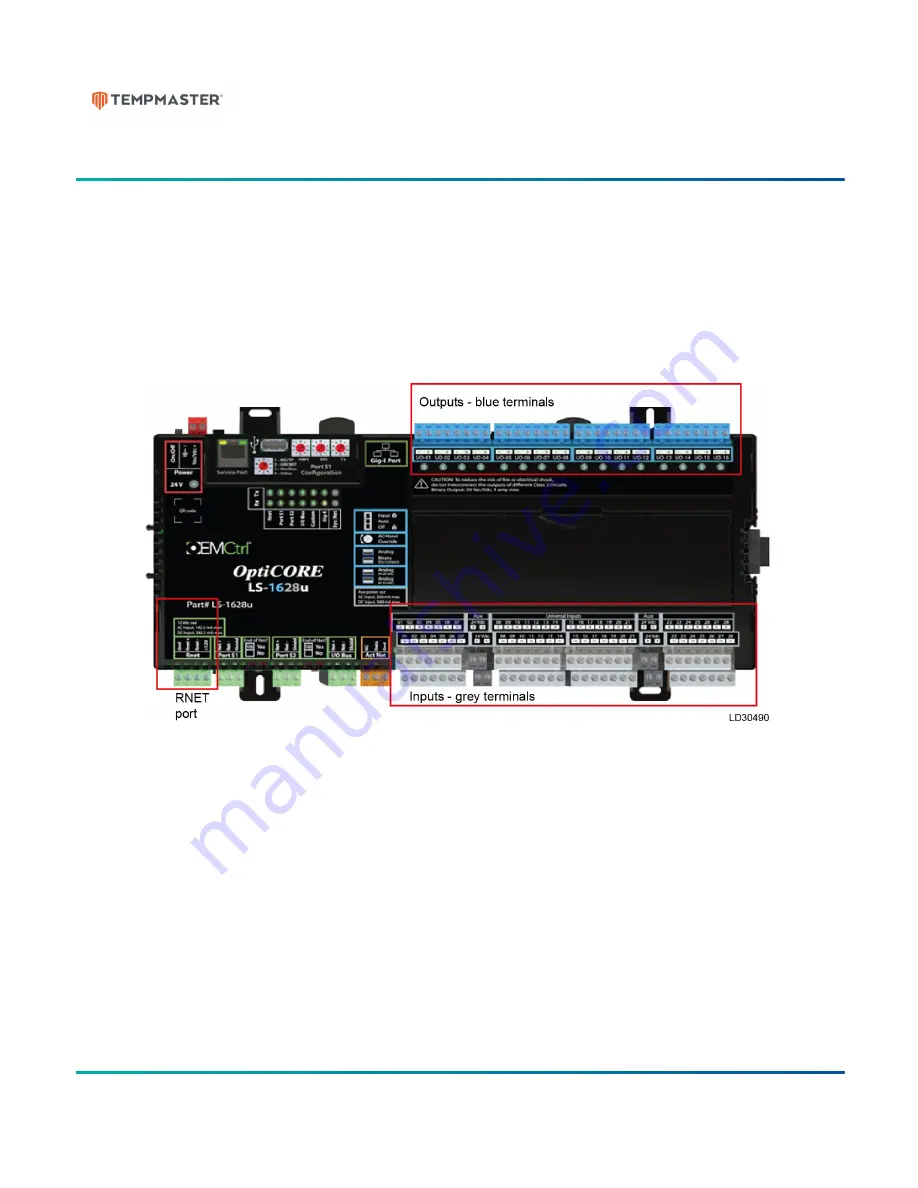

This start-up guide will guide you through the

necessary procedures to start-up the unit equipped

with an LS-1628 controller. Before turning on the

controller, be sure all wiring is completed and in

the proper location. All

input

connections (i.e. SAT

sensor) wire into the grey terminals located on the

bottom of the controller. All

output

connections

wire into the blue terminals located on top of the

controller.

Refer to the wiring diagram included with

the unit for the connections specific to this unit.

If installing a zone or room sensor, wire to TB5

terminal blocks, these will be factory wired to the

controller’s Rnet port located on bottom-left of the

controller.

Refer to the wiring diagram included with

the unit for the connections specific to this unit.

Figure 1: LS-1628 controller

Form Number: TPM54-SU2 (321) New Release

Issue Date: 2021-03-16