SYNCHRO EXCITE Class & Trend: Service & maintenance manual - rev. 2.0

Pagina 3.10

3.2.

BRAKE CONTROL

3.2.1.

M

ECHANICS

The motion of the pedals imparts a rotation to the primary shaft via the belts and pulley system.

The primary shaft is connected to the secondary shaft and so to the brake, by means of a belt. The

speed sensor (only on mains operated models) attached to the frame detects the heads of the screws

which secure the disk to the flywheel, and generates a signal proportional to the speed. On self

powered machine, the speed value is detected measuring a phase of the alternator.

3.2.2.

C

ONTROLS

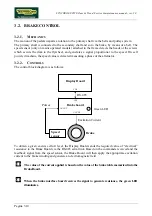

The control block diagram is as follows:

To obtain a given exercise effort level, the Display Board sends the required value of “electrical”

resistance to the Brake Board via the RS-485 serial link. Based on the commands received and the

feedback signal from the speed sensor, the Brake Board will then apply the appropriate excitation

current to the brake winding and generate an electromagnetic field.

The value of the current applied is based on the value of the brake table memorized into the

Brake Board.

When the brake interface board receives the signal to generate resistance, the green LED

illuminates.

Display Board

Brake board

RS-485

CN9

CN3

1-2/CN2

Brake

Excitation Current

3-4/CN2

Pulses

Speed

sensor

Green LED

Содержание Synchro Excite 500

Страница 1: ...SERVICE MAINTENANCE MANUAL REV 2 0 ...

Страница 2: ......

Страница 4: ......

Страница 10: ...SYNCHRO EXCITE Class Trend Service maintenance manual rev 2 0 Pagina vi Page intentionally left blank ...

Страница 48: ...SYNCHRO EXCITE Class Trend Service maintenance manual rev 2 0 Pagina 4 6 LIBYA DVB T ...

Страница 49: ...SYNCHRO EXCITE Class Trend Service maintenance manual rev 2 0 Page 4 7 Page intentionally left blank ...

Страница 50: ......

Страница 190: ...SYNCHRO EXCITE Class Trend Service maintenance manual rev 2 0 Pagina 9 50 Page intentionally left blank ...

Страница 201: ......