4. Operating Instructions

Fill Verification

The Fill Verification option is a method of checking the filling of the wells in a

microplate. Possible errors with the dispensing system as well as the aspiration

system can be recognised.

The Fill Verification only works with the OVERFLOW wash procedure.

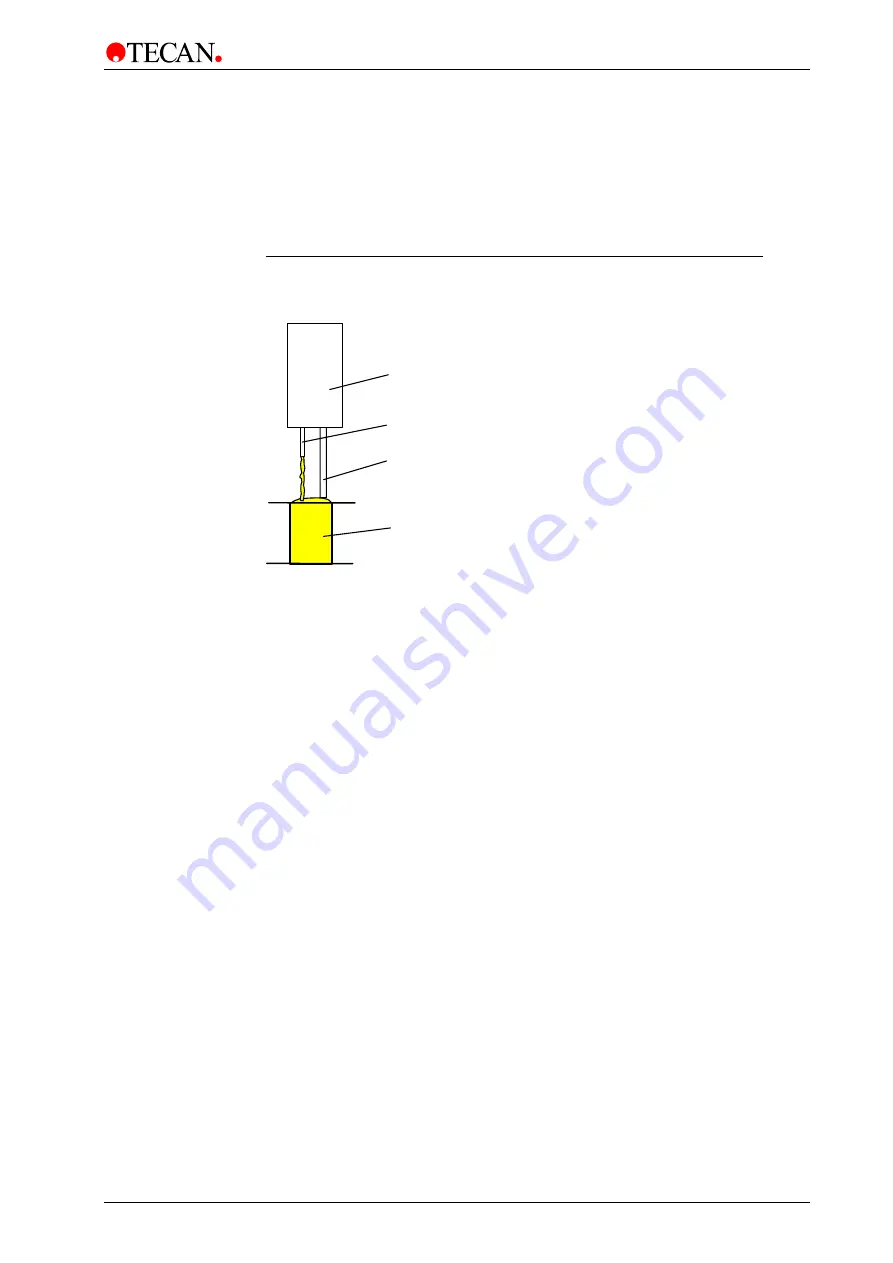

The wash buffer forms an electrical connection between the dispensing needles

and the aspirating needles. As soon as the wash liquid touches the aspirating

needles the electric circuit is closed.

Manifold

Dispensing needle

Aspirating needle

Well filled with washbuffer

The following errors can be detected using this method.

•

Fill Dispens Error

•

Fill Aspiration Error

•

Fill Function Error

Fill Dispens Error

The error messages

Inadequate

wash

,

Check

disp

path

are displayed.

These error messages appear if some of the needles are dispensing no or too

little solution. Possible errors could be a result of blocked dispensing needles,

bubbles in the dispensing channels, empty liquid bottles or the dispensing pump

no longer functions.

If no connection between the dispensing needles and the relevant aspirating

needles is made at least 30 µl before the end of the dispensing step, the wash

program will be interrupted.

Fill Aspiration Error

The error message

Fill

Asp

.

Err

. is displayed.

In order to prevent the wells from overflowing, the instrument checks when the

individual aspirating needles come into contact with the wash solution.

If this happens before

200

µl

has been dispensed into the wells the program is

stopped immediately. This can occur when the well was not or not completely

aspirated, due to a blocked aspirating needle / tube or the general aspiration

being too weak.

May 2003

Instructions for Use for Columbus Washer No. I 109 006 Rev No. 2.2

4-7