1-11

1. OUTLINE OF THE SYSTEM

EO10-33008

1. 5 ELCTRONICS SPECIFICATIONS

3

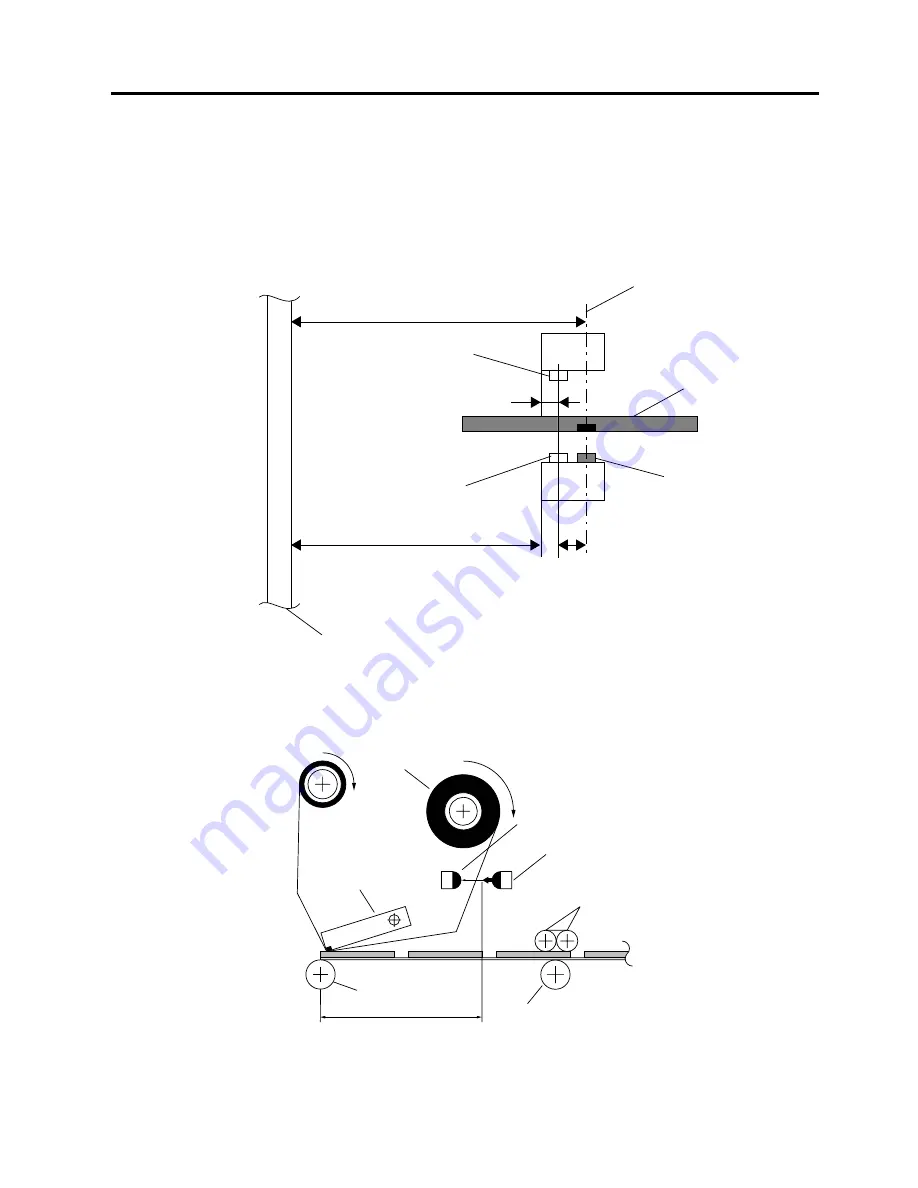

Media Sensor 2 (Fixed type)

Like media sensor 1, this sensor is comprised of the black mark sensor and the feed gap sensor.

If the detection point is positioned at the center of the media, there is no need to adjust the sensor

position.

■

Black Mark Sensor 2 (Reflective sensor)

This is a fixed sensor which detects black marks at the center of the tag paper.

■

Feed Gap Sensor 2 (Transmissive sensor)

This is a fixed sensor which detects label gaps at the center of the label.

Fig. 1-11

4

Ribbon end sensor (Transmissive sensor)

When printing in thermal transfer mode, this sensor detects the difference in potential between

the ribbon and the ribbon end to indicate the ribbon end. It is positioned 103.2 mm from the platen

and the detection point is 125.2 mm from the main frame.

Fig.1-12

143.7 mm

Center

19.1 mm

Tag Paper

Feed Gap Sensor 2

Feed Gap Sensor 2

10 mm

Black Mark Sensor 2

114.6 mm

Print Head

Ribbon

Ribbon End Sensor (LED)

Ribbon End Sensor (Tr)

Pinch

Roller

Platen

103.2 mm

Feed

Roller

Main Frame

Содержание B-880 series

Страница 3: ...TEC Thermal Printer B 870 880 QQ SERIES Owner s Manual ...

Страница 35: ......

Страница 36: ...PRINTED IN JAPAN EO1 33017 ...

Страница 56: ......

Страница 57: ......

Страница 58: ...PRINTED IN JAPAN EO10 33008 ...

Страница 146: ...6 59 6 DIAG TEST OPERATION EO18 33007 Fig 6 25 Bar code AUTO PRINT Fig 6 24 ...

Страница 176: ......

Страница 177: ......

Страница 178: ...PRINTED IN JAPAN EO18 33007 ...

Страница 179: ......

Страница 180: ......