E7-1

7. LOADING THE RIBBON

ENGLISH VERSION EO1-33016

7. LOADING THE RIBBON

7. LOADING THE RIBBON

WARNING!

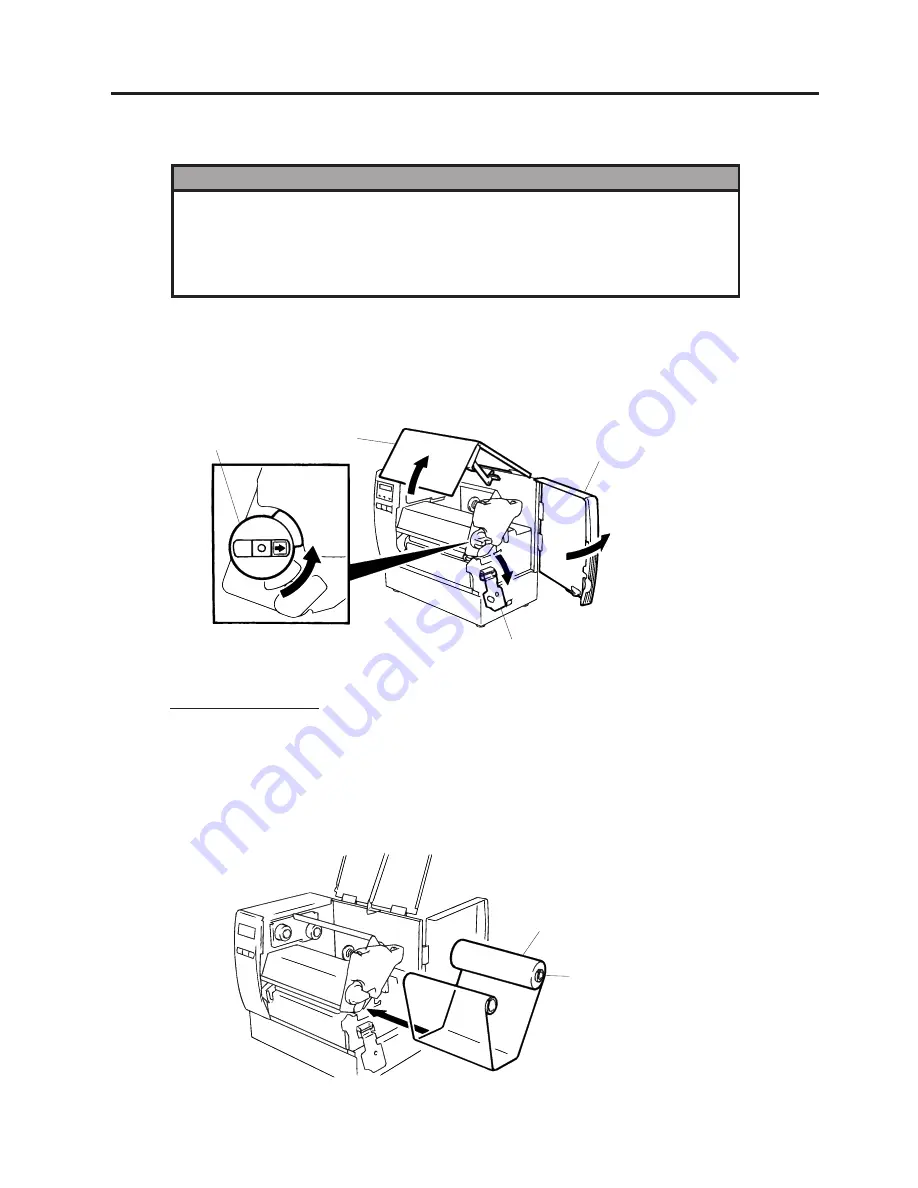

1. Do not touch moving parts. To reduce the risk that fingers, jewelry, clothing,

etc., be drawn into the moving parts, push the switch in the “OFF” position to

stop movement.

2. To avoid injury, be careful not to catch or jam your fingers while opening

or closing the cover.

Fig. 7-2

Head Lever Position

1

:

Labels or thin tag paper

2

:

Thick tag paper

OPEN: Ribbon/media replacement

3.

As Fig. 7-2 shows, unroll and loosen the ribbon a little.

4.

Insert the ribbon under the print block so that the ribbon supply end is positioned backside of the

printer.

Fig. 7-1

Ribbon

Ribbon Core

Right Side Cover

Top Cover

Head Lever

OPEN

Head Lock Plate

There are two types of media available for printing on, these are standard media and direct thermal media

(a chemically treated surface). DO NOT LOAD a ribbon when using a direct thermal media.

1.

Turn the power off and open both the top cover and the right side cover.

2.

Set the head lever to the “OPEN” position and release the head lock plate.

1

2

Содержание B-672-QQ

Страница 1: ...TEC Thermal Printer B 670 SERIES Owner s Manual ...

Страница 32: ......

Страница 33: ......

Страница 34: ...PRINTED IN JAPAN EO1 33016 E ...