7-2

OPERATOR CHECKLIST

Model C723

Operator Checklist

7

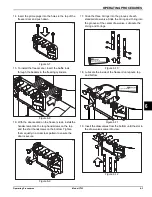

If your machine is air-cooled, check the condenser

for an accumulation of dirt and lint. Dirty

condensers will reduce the efficiency and capacity

of the machine. Condensers should be cleaned

monthly

with a soft brush.

Never

use

screwdrivers or other metal probes to clean

between the fins.

Note:

For machines equipped with an air filter, it will be

necessary to vacuum-clean the filters monthly.

WARNING!

Always disconnect electrical

power prior to cleaning the condenser. Failure to follow

this instruction may result in electrocution.

If your machine is water-cooled, check the water

lines for kinks or leaks. Kinks can occur when the

machine is moved back and forth for cleaning or

maintenance. Deteriorated or cracked water lines

should be replaced only by an authorized Taylor

distributor.

Winter Storage

If the place of business is to be closed during the winter

months, it is important to protect the freezer by following

certain precautions, particularly if the building is subject

to freezing conditions.

Disconnect the freezer from the main power source to

prevent possible electrical damage.

On water-cooled freezers, disconnect the water supply.

Relieve pressure on the spring in the water valve. Use air

pressure on the outlet side to blow out any water

remaining in the condenser.

This is extremely

important.

Failure to follow this procedure may cause

severe and costly damage to the refrigeration system.

Your local Taylor distributor can perform this winter

storage service for you.

Wrap detachable parts of the freezer such as dasher,

blades, dasher shaft, and freezer door, and place them in

a protected, dry place. Rubber trim parts and gaskets can

be protected by wrapping them with moisture-proof

paper. All parts should be thoroughly cleaned of dried mix

or lubrication, which can attract mice and other vermin.

It is recommended that a service technician perform

winter storage draining to ensure all water has been

removed. This will guard against freezing and rupturing

of the components.

Содержание C723

Страница 14: ...3 4 SAFETY Model C723 Safety 3 Notes ...

Страница 42: ...6 10 OPERATING PROCEDURES Model C723 Operating Procedures 6 Notes ...

Страница 48: ...9 2 PARTS REPLACEMENT SCHEDULE Model C723 Parts Replacement Schedule 9 Notes ...

Страница 52: ...10 4 LIMITED WARRANTY ON EQUIPMENT Model C723 Limited Warranty on Equipment 10 Notes ...

Страница 56: ...11 4 LIMITED WARRANTY ON PARTS Model C723 Limited Warranty on Parts 11 Notes ...