5-4

USER INTERFACE

Model C612

User Interface

5

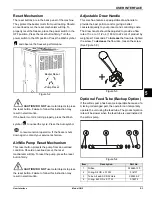

The feed tube serves two purposes. One end of the tube

has a hole and the other end does not.

1. Normal Operation

During normal operation the end of the feed tube with

the hole is placed into the mix inlet hole. Every time

the draw handle is raised, new mix and air from the

hopper flow into the freezing cylinder. This keeps the

freezing cylinder properly loaded and maintains

overrun.

2. Long

No Sale

Periods

During long

no sale

periods, the machine can be

placed in the Standby mode. This maintains product

temperatures below 40°F (4.4°C) in both the hopper

and the freezing cylinder and helps prevent

overbeating and product breakdown.

To place the machine in the Standby mode, press the

STANDBY key. Remove the air orifice. Lubricate the

O-rings on the end of the feed tube without the hole.

Place that end of the tube into the mix inlet hole. This will

prevent any mix from entering the freezing cylinder.

Note:

The air orifice is used to meter a certain amount

of air into the freezing cylinder. The air orifice maintains

overrun and allows enough mix to enter the freezing

cylinder after a draw.

Operating Screen Descriptions

The fluorescent display in the center of the control panel

is normally blank during the daily operation of the

machine. The display is activated when the SEL symbol

or the Manager's Menu is selected. The display screen

will also alert the operator of specific faults detected by

the control.

Power Up

When the machine is powered, the control system will

initialize to perform a system check. The screen will

display INITIALIZING. There are four types of data the

system will check: LANGUAGE, SYSTEM DATA,

CONFIG DATA, and LOCKOUT DATA.

During the INITIALIZING... LANGUAGE screen, the

alarm will be on. If the system detects corrupt data during

INITIALIZING, the following display will alert the operator

that the control settings may have been changed:

See NVRAM FAULT for instructions if the above

message appears on the screen.

Once the system has initialized, the SAFETY TIMEOUT

screen will display and the alarm will be on.

The SAFETY TIMEOUT screen will be displayed with the

alarm on for 60 seconds or until any control symbol is

selected.

After the safety timeout has been completed and the

power switch is OFF, the following screen is displayed:

Power Switch ON

When the power switch is placed in the ON position, the

control panel press keys become operative. The

fluorescent display will either be blank or indicate that the

machine has been cleaned.

Brush-Clean Counter

The brush-clean counter (item 9 on page 5-1) will display

the number of hours since the freezer was last

brush-cleaned. After hour 99, it will change to a letter and

a number. (Example: A0, A1, B0, B1, etc.)

NVRAM FAULT

RESET TO DEFAULTS

PRESS SEL KEY

SAFETY TIMEOUT

ANY KEY ABORTS

POWER SWITCH OFF

- = - = - = - = - = -

UNIT CLEANED

UNIT CLEANED

Содержание C612

Страница 8: ...1 4 TO THE INSTALLER Model C612 To the Installer 1 Notes...

Страница 54: ...9 2 PARTS REPLACEMENT SCHEDULE Model C612 Parts Replacement Schedule 9 Notes...

Страница 58: ...10 4 LIMITED WARRANTY ON EQUIPMENT Model C612 Limited Warranty on Equipment 10 Notes...

Страница 62: ...11 4 LIMITED WARRANTY ON PARTS Model C612 Limited Warranty on Parts 11 Notes...