The data described in this handbook are purely a guide. TAU reserves the right to change them in any moment.

The manufacturer reserves the right to modify or improve products without prior notice. Any inaccuracies or errors found in this handbook will be corrected

in the next edition.

When opening the packing please check that the product is intact. Please recycle materials in compliance with current regulations.

This product may only be installed by a qualified fitter. The manufacturer declines all liability for damage to property and/or personal injury

deriving from the incorrect installation of the system or its non-compliance with current law (see Machinery Directive).

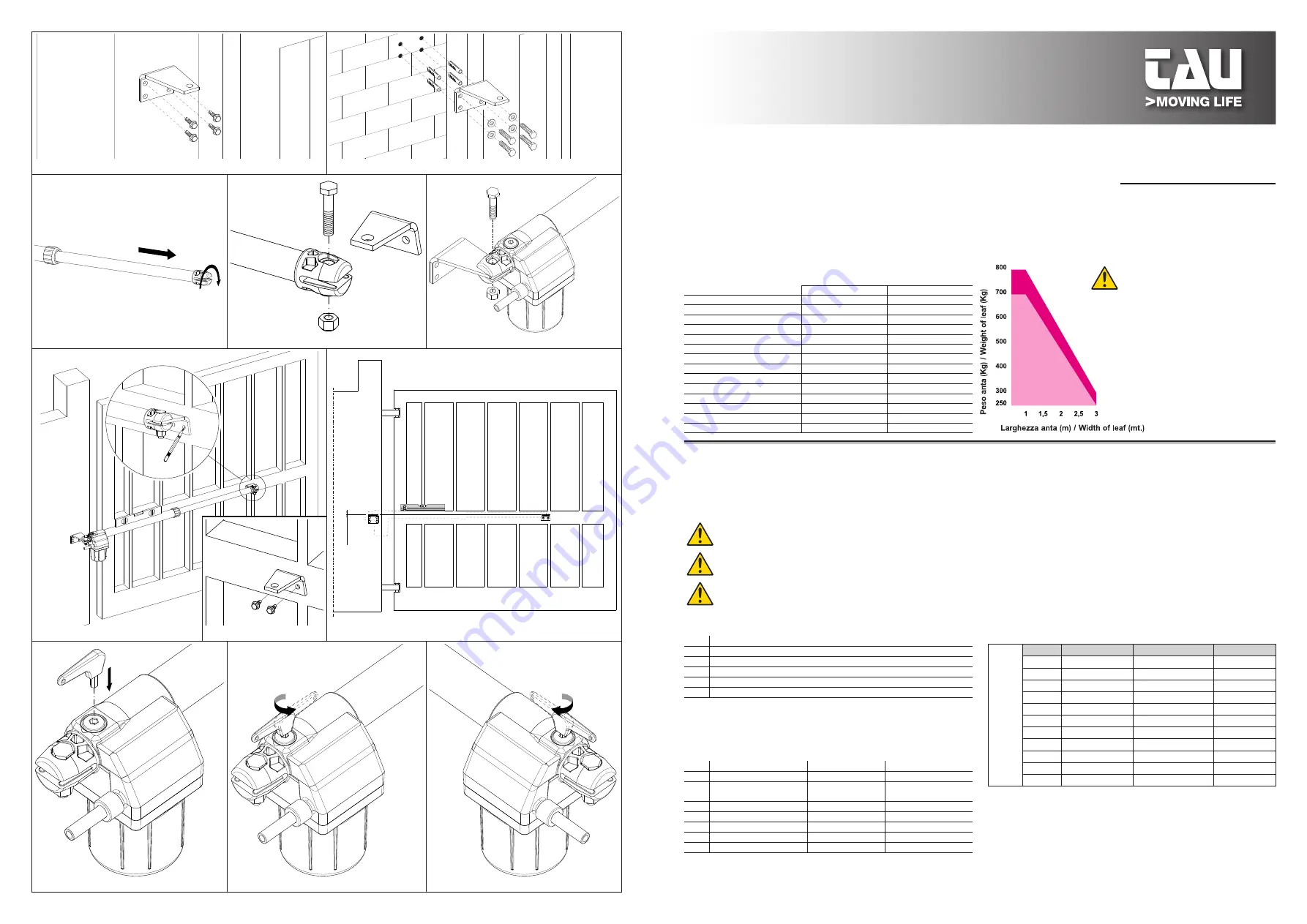

pict. 7

pict. 6

pict. 8

pict. 11

pict. 13

1

2

pict. 9

pict. 10

pict. 14

pict. 15

pict. 16

LEFT

180°

RIGHT

180°

0 mm

pict. 12

USE AND MAINTENANCE MANUAL

EKOSWING

Swing Gate Operator - Residential/Communities

English

TECHNICAL CHARACTERISTICS OF THE EKOSWING SERIES

EKOSWING

EKOSWING-B

Power input

230V AC ±10%

230V AC ±10%

Motor power input

230V AC ±10%

18V DC

Frequency

50/60 Hz

50/60 Hz

Capacitor

8 µf

-

Absorbed current (no load)

1,2 ÷ 1,7 A

0,6 A

Absorbed power (no load)

280 W

100 W

Motor speed (no load)

900 rpm

2100 rpm

Useful travel

443 mm

443 mm

Thermal protection trips at

150 °C (autoreset)

-

Reduction ratio

1/27

1/34

Operating temperature

from –20 °C to +55 °C from –20 °C to +55 °C

Weight

6,9 Kg

6,8 Kg

Motor IP

IP 53

IP 53

Work cycle

40 %

100 %

90° travel time

17 sec.

15 sec.

EK

OS

W

IN

G

EK

OS

W

ING

-B

For The installation of blank swing gates,

functioning cannot be guaranteed in the

presence of wind.

D_MNL0EKOSWING

23-11-2012 - Rev.05

DESCRIPTION

The

EKOSWING

automated system for swing gates is an electro-mechanical non-

reversing actuator that transmits motion to the leaf via a worm screw system.

The actuator is available in 12V DC and 230V AC versions.

The non-reversing system ensures the leaf is mechanically locked when the motor is

not operating. A convenient and safe release system with customised key makes it

possible to manually move the leaf in the event of a malfunction or of a power failure.

ATTENTION:

The correct operation and the declared specifications only apply if

TAU accessories and safety devices are used.

In the absence of a mechanical clutch, the use of a control unit with an

adjustable electronic clutch, or the installation of a sensitive edge, is

required in order to ensure crush-proof safety.

The EKOSWING automated system was designed and built for con-

trolling vehicle access. Avoid any other use whatever.

ACTUATOR PARTS (pict.1)

Pos. Description

1

Actuator

2

Release device

3

Rod

4

Wing connection bracket

5

Rear bracket

DIMENSIONS (pict

.2)

INSTALLATION (pict

.3)

Electrical set-up (standard system - EKOSWING)

Pos. Description

Cables (230V AC)

Cables (12V DC)

1 Actuator

4x1,5 mm²

2x2,5 mm² + 3x0,5 mm²

2 Control unit

3x1,5 mm²

(power supply)

3x1,5 mm²

(power supply)

3 TX photocells

4x0,5 mm²

4x0,5 mm²

4 RX photocells

2x0,5 mm²

2x0,5 mm²

5 Key-operated selector switch

3x0,5 mm²

3x0,5 mm²

6 Flashing light and aerial

2x1 mm² + 1RG58

2x1 mm² + 1RG58

7 Mechanical stops

-

-

Notes:

• Use suitable tubes and/or hoses to lay electric cables

• Choose short routes for cables and keep power cables separate from control

cables.

Preliminary checks

Prior to installing the automation, make all structural modifications in order to ensure

safety distances and protect and segregate areas in which people may be exposed to

the risk of crushing, shearing, dragging or similar dangers.

• Make sure the existing structure is sufficiently sturdy and stable;

• the mechanical parts must conform to the provisions of current Safety Standards;

• leaf length in compliance with the actuator specifications;

• regular and uniform movement of the leaves, without any friction and dragging

during their entire travel;

• stiff hinges in good conditions;

• presence of both opening and closing mechanical limit stops;

• presence of an efficient earthing for electrical connection of the actuator.

Perform any necessary metalwork job before installing the automated system.

The condition of the gate structure directly affects the reliability and safety of

the automated system.

Installation dimensions (pict.4)

Determine the fitting position of the actuator with reference to pict.4.

Check with care if the distance between the open leaf and any obstacles (walls, fenc-

es etc.) is higher than the actuator dimensions.

E

K

O

S

W

I

N

G

X°

A (mm)

B (mm)

C (mm)

90

150

200 ÷ 260

20 mm

90

200

160 ÷ 220

20 mm

90

250

120 ÷ 220

20 mm

90

300

85 ÷ 155

20 mm

100

150

175 ÷ 235

20 mm

100

180

140 ÷ 205

20 mm

100

200

120 ÷ 190

20 mm

100

230

95 ÷ 160

20 mm

110

175

120 ÷ 190

20 mm

110

200

95 ÷ 160

20 mm

110

225

60 ÷ 130

20 mm

When measurement “C” is greater/smaller than 20 mm, increase/diminish measure

-

ment “B” by the difference (e.g.: if C= 25mm, increase “B” by 5mm), making sure that

it does not exceed the limits shown in the table.

If the pillar dimensions or the hinge position do not allow the installation of the actua-

tor, a niche on the pillar, as shown in pict. 5, should be created in order to maintain

the A dimension as determined. The niche should be dimensioned in such a way to

enable easy installation, actuator rotation and operation of the release device.

GB - Translation of original instructions