0. GENERAL

IOM manual

–

SG series

6

Electrical hazard:

These are examples of other categories that can occur. They fall under the ordinary hazard

levels and may use complementing symbols:

➢

Crush hazard

➢

Cutting hazard

➢

Arc flash hazard

0.3.

Safety

WARNING:

➢

The operator must be aware of safety precautions to prevent physical injury.

➢

Pump must not be used if people are in water

➢

Leakage of pump lubricants may cause water pollution

➢

Proper plug must be provided according to local and national standards

➢

Never operate the pump suspended in air. The recoil may result in serious injury or

death

➢

Do not use the pump in explosion hazard zones.

➢

Any pressure-containing device can explode, rupture, or discharge its contents if it is

over-pressurized. Take all necessary measures to avoid over-pressurization.

➢

Operating, installing, or maintaining the unit in any way that is not covered in this

manual could cause death, serious personal injury, or damage to the equipment. This

includes any modification to the equipment or use of parts not provided by the

manufacturer. If there is a question regarding the intended use of the equipment,

please contact the manufacturer representative before proceeding.

➢

This manual clearly identifies accepted methods for disassembling units. These

methods must be adhered to. Trapped liquid can rapidly expand and result in a violent

explosion and injury. Never apply heat to impellers, propellers, or their retaining

devices to aid in their removal.

➢

Do not change the service application without the approval of an authorized Tapflo

representative.

➢

In case any instructions in this manual are unclear or any information is lacking, please

contact Tapflo before handling the pump.

CAUTION:

You must observe the instructions contained in this manual. Failure to do so could

result in physical injury, damage, or delays

0.4.

User safety

General safety rules

These safety rules apply:

➢

Always keep the work area clean.

➢

Pay attention to the risks presented by gas and vapours in the work area.

➢

Avoid all electrical dangers. Pay attention to the risks of electric shock or arc flash

hazards.

➢

Always bear in mind the risk of drowning, electrical accidents, and burn injuries.

NOTICE:

Never operate a unit unless safety devices are installed. Also see specific information

about safety devices in other chapters of this manual.

Содержание SG Series

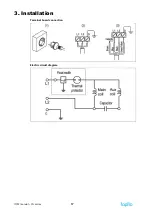

Страница 17: ...3 Installation IOM manual SG series 17 Terminal board connection Electric circuit diagram...

Страница 31: ......