5. Maintenance and inspection

IOM manual

–

SG series

24

NOTICE:

➢

The drained oil must be disposed according

to national and local regulations.

➢

The gasket and the O-ring for the oil filler

plug must be replaced with a new part at

each oil inspection and change.

Model

Oil volume

SG

150 ml

5.5.

Disassembly and reassembly procedure

DANGER:

Disconnect and lock out electrical power before installing or servicing the unit

WARNING:

Make sure to perform a test operation when starting the pump after a reassembly

.

If the pump

was assembled improperly, it may leakage abnormal operation or electrical shock

.

CAUTION:

Wear protective gloves. A worn impeller and/or pump housing can have very sharp edges.

5.5.1.

Disassembly procedure

NOTICE:

➢

Before disassembling, make sure to drain the oil from the pump.

➢

Mechanical seal should be replaced only when broken or worn (see chapter

5.4.

Oil inspection and change

).

1. Suction cover [8] and pump casing [13] disassembly

Remove the bolt [1], washer [2], to remove the bottom plate [3]; then remove the screw

[5] and washer [6] to remove the stand [7], suction cover [8] and pump casing [13].

2. Impeller [12] disassembly

Remove the doomed nut [9], spring washer [10] and washer [11] to remove impeller [12],

washer [15], sand guard [16], shaft sleeve [17].

3. Rear wearing plate [14] disassembly

Remove the wearing plate [14] from the back casing [19].

4. Oil casing [19] and mechanical seal [22] disassembly

After removing the screw [18], remove the oil casing [19] (when doing this, be careful not

to damage sealing face of the mechanical seal [22]) and casing gasket [26]. Remove the

mechanical seal [22] from the main shaft.

NOTICE:

Mechanical seal replacement must be handled by the qualified staff, contact Tapflo

for more information.

Содержание SG Series

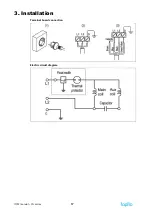

Страница 17: ...3 Installation IOM manual SG series 17 Terminal board connection Electric circuit diagram...

Страница 31: ......