3. Installation

IOM manual

–

SG series

14

5. The discharge hose can be routed vertically or

horizontally but must be without sharp bends.

6. Use the shortest possible length of discharge

hose or piping and minimize the number of

bends. Makes sure that the end of the hose

(discharge side) is lifted above the water

surface. If the hose ending is submerged in

water, it may cause the water to flow back

when the pump is stopped. If the end of the

hose is located at lower level than the source

water surface, water may continue to flow out

even after the pump is stopped.

WARNING:

If an excessive amount of sediment is drawn into the pump, it may cause the pump to wear,

which can lead to current leakage or electrical shock.

NOTICE:

Appropriate hose or pipe materials must be provided by the user, for more information contact

Tapflo.

7. During operation the pump must be placed upright position. If there is a risk that the pump

could be buried under the sediment, place the pump on a base, e.g. concrete blocks.

3.5.

Electrical connections

ELECTRICAL HAZARD:

➢

A certified electrician must supervise all electrical work. Follow the national and local

regulations.

➢

Before starting to work on the unit, make sure that the unit and the control panel are

isolated from the power supply and cannot be energized. This applies to the control

circuit as well.

➢

Leakage into the electrical parts can damage it or blow the fuse.

➢

Keep

the end of the motor cable out of the water.

➢

Make sure that all unused conductors are insulated.

➢

There is a risk of electrical shock or explosion if the electrical connections are not

correctly carried out or if product is damaged.

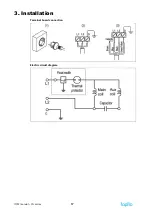

Содержание SG Series

Страница 17: ...3 Installation IOM manual SG series 17 Terminal board connection Electric circuit diagram...

Страница 31: ......