3.

MAINTENANCE

IOM manual Tapflo PTL Hose pumps

27

3.8.

Hose cleaning

The hose can be cleaned in place without disassembly. It can be done with water or any other

appropriate agent as long as it is compatible with the hose material. Check not only the chemical

compatibility but also the allowable temperature for the utilized hose.

3.9.

Hose replacement

The PTL pump hose is a consumable part that may break due to excessive wear, which can lead to

leakage inside the pump casing. The service life of the hose is affected by various factors such as

rotor speed, rollers adjustment, discharge pressure, pumped liquid abrasiveness, chemical

composition, and viscosity. Since it is impossible to definitively determine the lifetime of the hose,

it is important to schedule preventive maintenance.

The pump can be optionally equipped with a hose leak detector or that, when coupled with

appropriate automation, can immediately turn off the pump and display an alarm in case of hose

rupture. It is recommended to record and store information about operating conditions and the

number of working hours before the malfunction, and use it to schedule preventive maintenance.

The more uniform the pump operating conditions, the more repeatable the hose life will be. See

4.3

“

Hose leak detector

”

.

In order to avoid costly downtime of the pump, it is recommended to inspect the hose after about

90% of the lifetime of the first hose as part of preventive maintenance.

The hose can be replaced without the whole pump disassembly. However, if you experienced a

hose rapture, before starting of this procedure, drain the pump from leaked medium according to

section 3.7.

“

Casing emptying procedure

”

and clean it thoroughly according to section

3.10.

“

Pump

casing cleaning procedure

”

.

For proper pump operation, it is necessary to lubricate the hose. Failure to fulfil this requirement

result in generating increased temperature and reducing the working parts' lifespan.

NOTE!

Make sure that suction and discharge valves are closed before disconnecting of the pump

from installation.

NOTE!

Proceed with this procedure only after familiarizing oneself with the instructions at the

beginning of section

3.

“

Maintenance

”

and all safety instruction in chapter

1.8.

“

Health and safety

”

.

NOTE!

New hose must be lubricated prior to operation. Use only silicon grease LOCTITE

®

8104

™

.

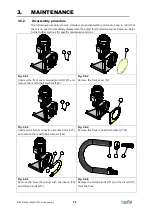

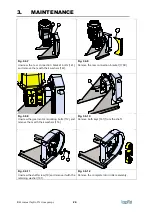

Fig. 3.9.1

Run the pump and position the rotor so

that only one roller is pressing against the hose.

Fig. 3.9.2

Disconnect power supply from the motor.

Unscrew the front cover mounting bolts [141] and

remove them with their washers [142].

Содержание PTL Series

Страница 63: ......