3.

MAINTENANCE

IOM manual Tapflo PTL Hose pumps

26

3.6.3.

Test run

We recommend you to conduct a test run of the pump before installing it in the system, so no

liquid gets wasted if the pump leaks or perhaps does not start accordingly to wrong assembly of

the pump.

After two weeks of operation retighten the nuts with appropriate torque.

3.7.

Casing emptying procedure

If you experienced hose rapture, take health and safety precautions appropriate to the pumped

liquid. Be prepared to pick up the leaked medium that fills the pump housing.

Make sure that suction and discharge valves are closed before draining.

Pump size

PTL9/13

PTL17

PTL25

PTL30

PTL45

Casing volume [L]

0.6

1.3

3.5

8

20

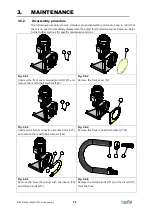

Fig. 3.7.1

Place a drip pan under the drain plug.

NOTE!

Make sure the drip pan is large enough to

contain the whole amount of lubricant that is inside

the pump.

Fig. 3.7.2

Unscrew the plug [33] and empty the pump form the

leaked medium.

NOTE!

If the pump is casing equipped any sensor

instead of plug, unscrew the sensor to drain the pump.

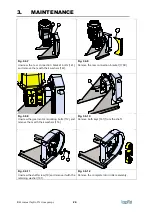

NOTE!

If the pump is oriented with the connections

facing upwards, you can initiate drainage by

unscrewing a few front cover bolts [141] located at the

bottom of the casing [11] and then pulling the front

cover [12].

Содержание PTL Series

Страница 63: ......