Inspection before starting work

11

1

2

3

4

5

6

7

8

9

10

11

Chapter 1

4.

Inspection before starting work

Before starting work, execute inspection (including cleaning, lubrication) of each part.

Place

Checking

Covers

Are covers attached correctly?

Upper thread

Is thread passed to each part correctly?

Is tension adequate?

Does thread entwine around frame/drive system?

Under thread

Is under thread (bobbin case) set to rotary hook correctly?

Is tension adequate?

Needle

Is needle bent?

Is direction of needle correct?

Is needle broken?

Rotary hook (p.207)

Is cleaning/lubrication performed in adequate frequency?

Tension base switch (p.64)

Is the switch of head to use turned ON?

Is the switch of unused head turned OFF?

Needle bar suspension lever (p.65)

Is the lever of head to use set to ON?

Is the lever of unused head set to OFF?

Middle thread guide adjusting lever

Is position correct?

Jog remote-controller (p.25)

Is it contained in the pocket?

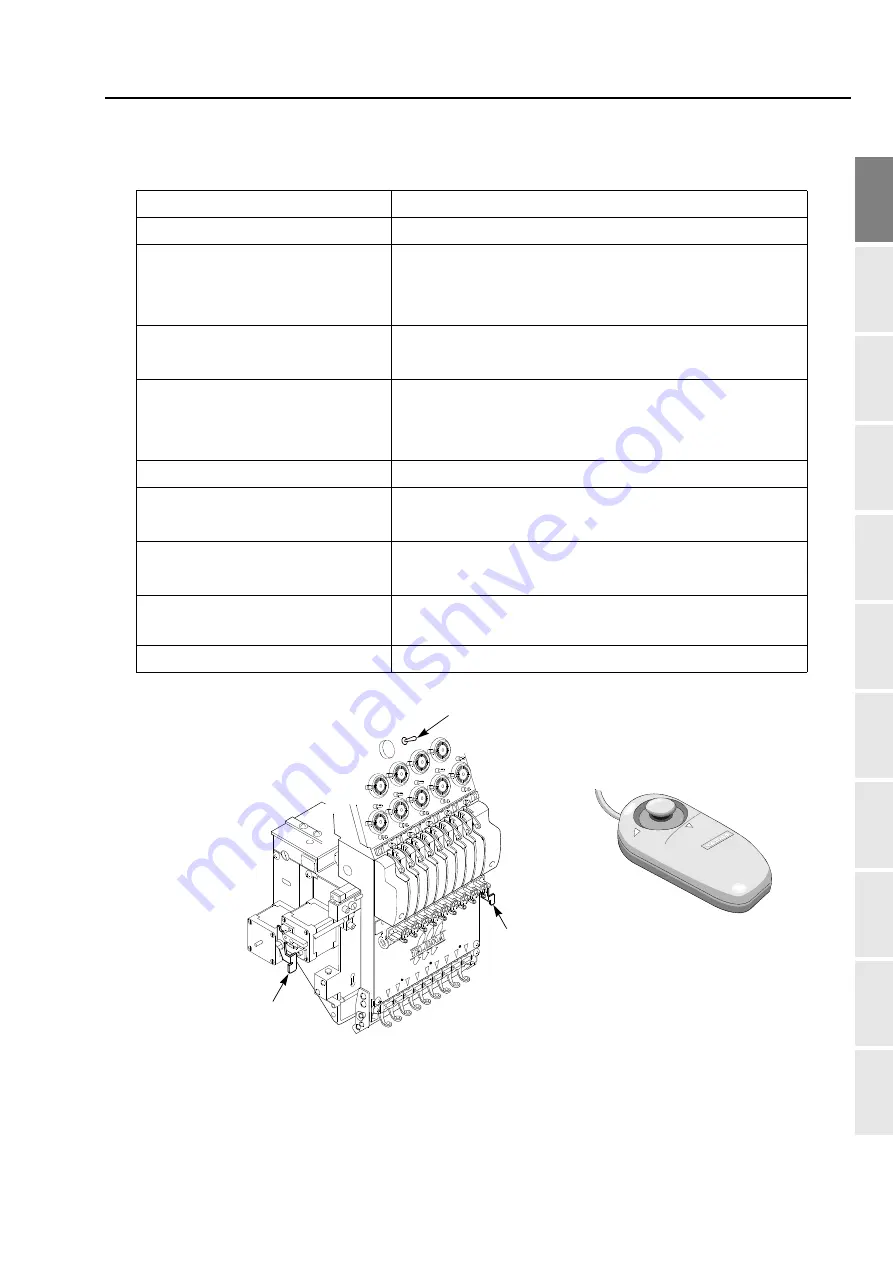

Tension base switch

Middle thread guide adjusting lever

Jog remote-controller

(Option for multi-head machine)

Needle bar suspension

lever

(Equipped to only multi-

head machine)

RR07

Содержание TEMX-C Series

Страница 13: ...To search from the menu key ...

Страница 25: ...Inspection before starting work 12 Chapter 1 ...

Страница 39: ...How to use each part 26 Chapter 2 ...

Страница 40: ... E 1 2 3 4 5 6 7 8 9 10 11 27 PT10 Chapter 3 Screen 1 Screen display 28 2 Message display 31 ...

Страница 104: ...To stop the machine 91 1 2 3 4 5 6 7 8 9 10 11 Chapter 5 PT10 4 To make Frame Limit Setting effective YES ...

Страница 147: ...Other functions that must be remembered 134 Chapter 5 ...

Страница 171: ...To move the frame to the position registered 158 Chapter 6 ...

Страница 189: ...Design stored in USB memory 176 Chapter 7 ...

Страница 204: ...Functions concerning optional device 191 1 2 3 4 5 6 7 8 9 10 11 Chapter 8 4 To use air compressor YES RR07 ...